Point inspection standard configuration method based on front point inspection and equipment point inspection system

A configuration method and spot inspection system technology, applied in database management systems, structured data retrieval, special data processing applications, etc., can solve the problem of low systematization of equipment spot checks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

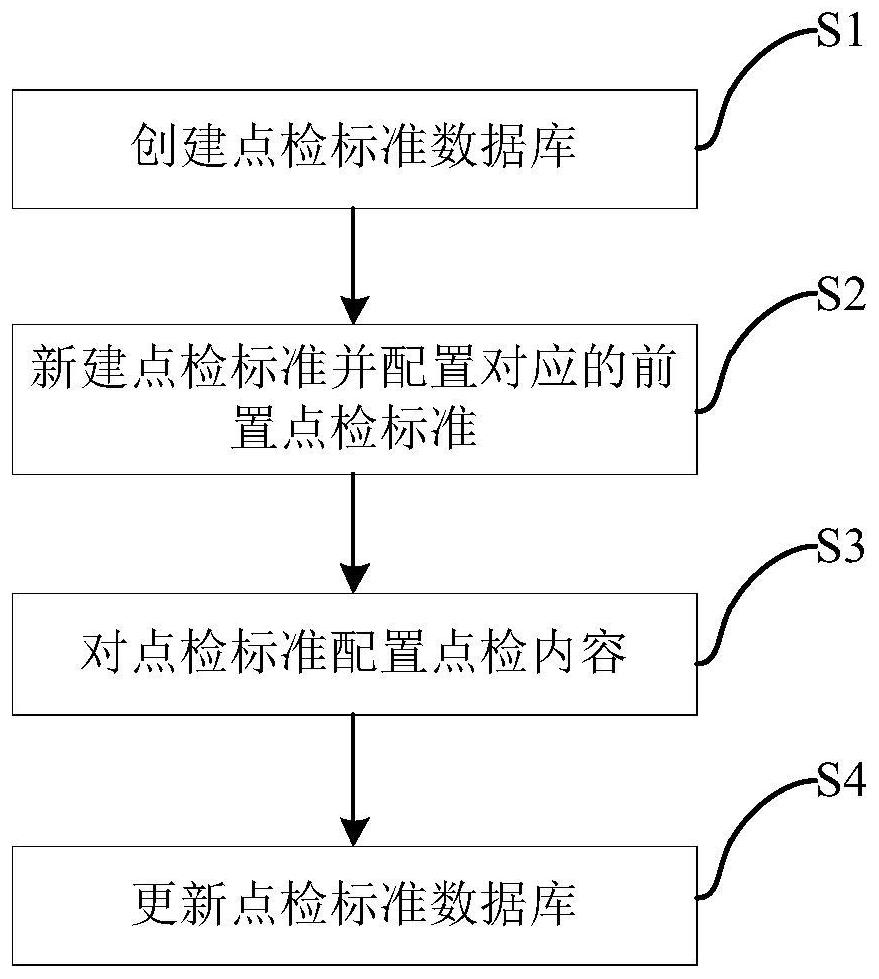

[0051] Such as figure 1 As shown in FIG. 2 , it is a flow chart of the inspection standard configuration method based on pre-inspection in this embodiment. This embodiment specifically includes the following steps:

[0052] S1: Create an inspection standard database.

[0053] Specifically, first of all, according to the inspection items of the equipment inspection (such as air compressor inspection, electric hoist crane inspection, electric welding machine inspection, etc.) , Whether the overload limiter is effective, whether the shell of the electric hoist reel is deformed, etc.) Create corresponding spot inspection standards. Described inspection standard comprises self-defined inspection standard and fixed inspection standard according to whether the user has modification authority, and described self-defined inspection standard is the user maintenance level, and in specific implementation, described self-defined inspection standard is input box The formation is provided...

Embodiment 2

[0081] An equipment inspection system in this embodiment can adopt the pre-inspection-based inspection standard configuration method described in Embodiment 1 to configure the inspection standards during equipment inspection, and configure the inspection standards based on the configured inspection standards. The equipment performs spot check work, so as to realize the systematization of equipment spot check work.

[0082] Such as Figure 4 Shown is a structural block diagram of an equipment inspection system in this embodiment. This implementation includes a spot check standard configuration module 1, a spot check database 2, an ID configuration module 3, an ID acquisition module 4, a matching module 5, a spot check record query module 61, a spot check entrance generation module 62, a spot check standard acquisition module 7, Display module 8 , data entry module 9 , learning prediction module 10 and to-do notification module 11 . in:

[0083] The inspection standard config...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com