Code scanning equipment with automatic calibration camera and millimeter wave radar

A millimeter-wave radar and automatic calibration technology, which is applied to instruments, image analysis, image data processing, etc., can solve the problems of low calibration accuracy of cameras and millimeter-wave radar, heavy labor, and low accuracy of target simulation equipment placement. Achieve the effect of large stroke, high degree of automation and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

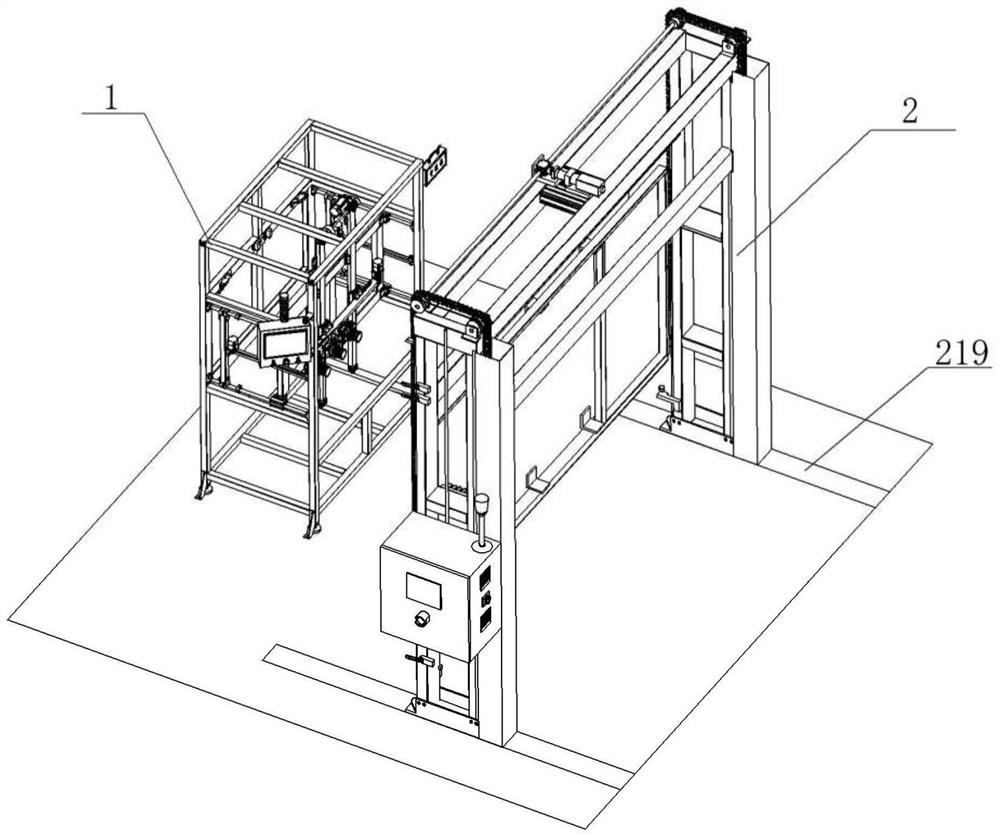

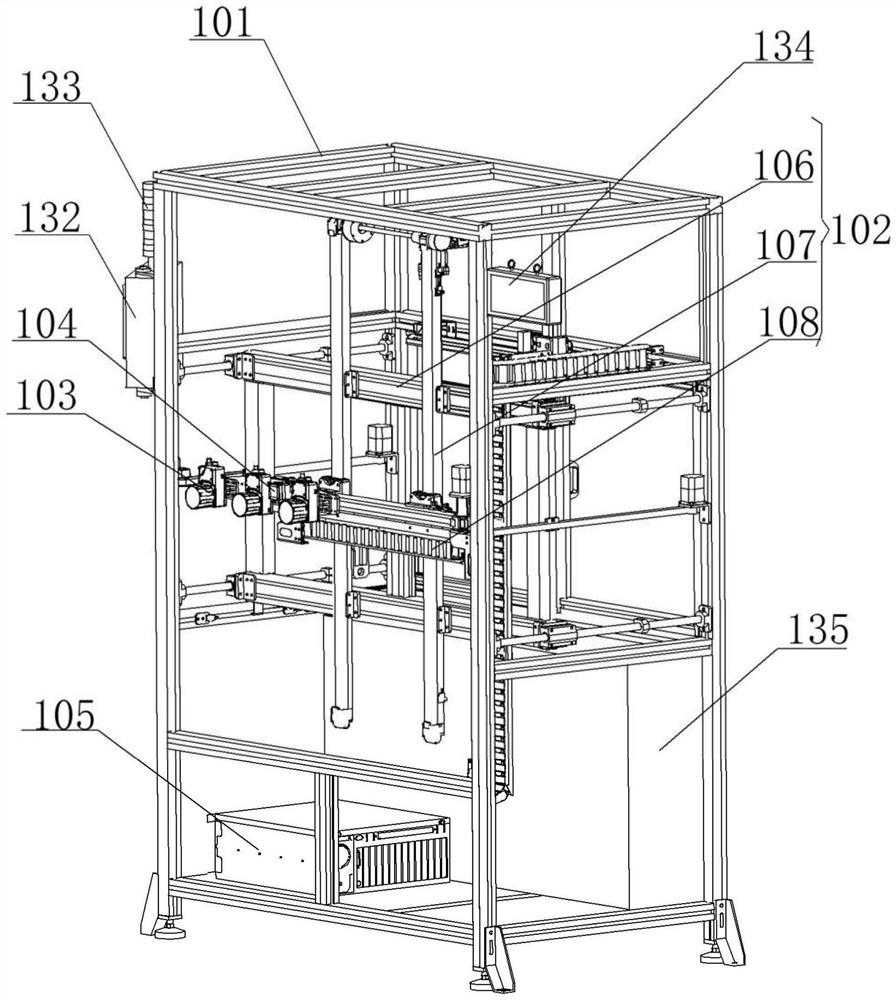

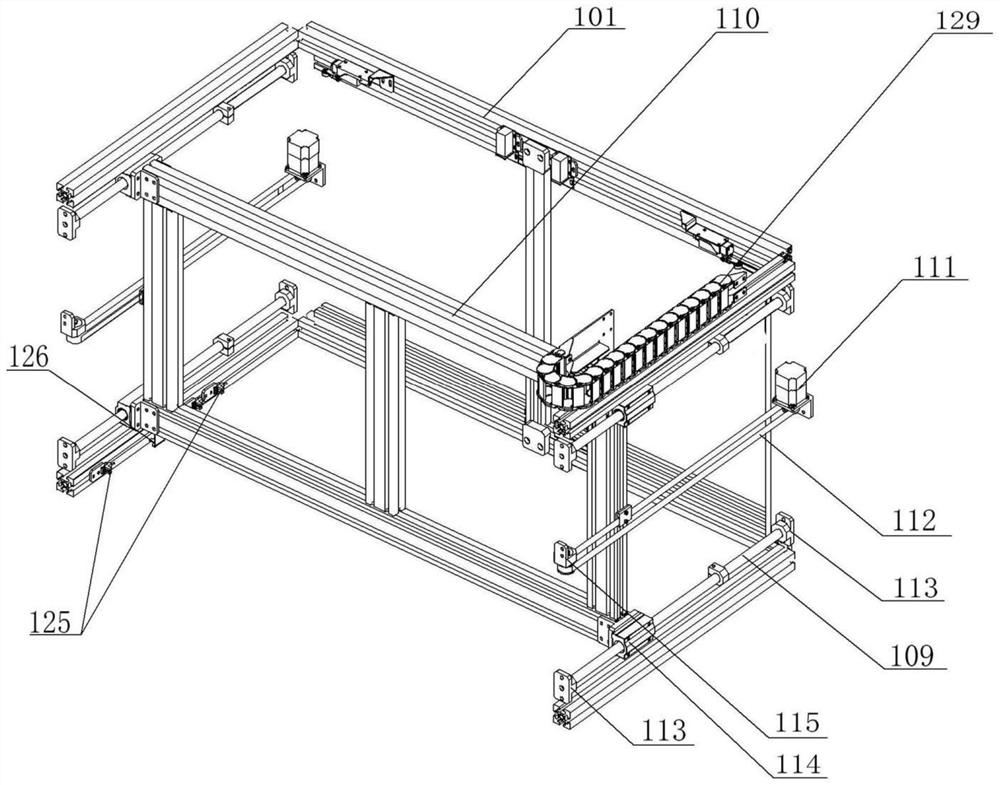

[0033] see Figure 1-8 Shown:

[0034] The present invention provides a code-scanning device with an automatic calibration camera and a millimeter-wave radar, comprising a code-scanning device 1 and a calibration device 2, the calibration device 2 being arranged in front of the code-scanning device 1; the code-scanning device 1 includes a frame body 101, a three-axis moving mechanism 102, a code scanning device 103, a millimeter-wave radar rangefinder 104, and an industrial computer 105; The shaft moving mechanism 102 is connected, and is driven by the three-axis moving mechanism 102 to move along the front and back, up and down, and left and right three axes; The millimeter-wave radar rangefinder 104 is connected to the industrial computer 105 respectively, and can be connected by wire or wireless communication. The industrial computer 105 is located at the bottom of the frame body 101; the calibration device 2 faces the code scanning device 103 and the millimeter-wave radar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com