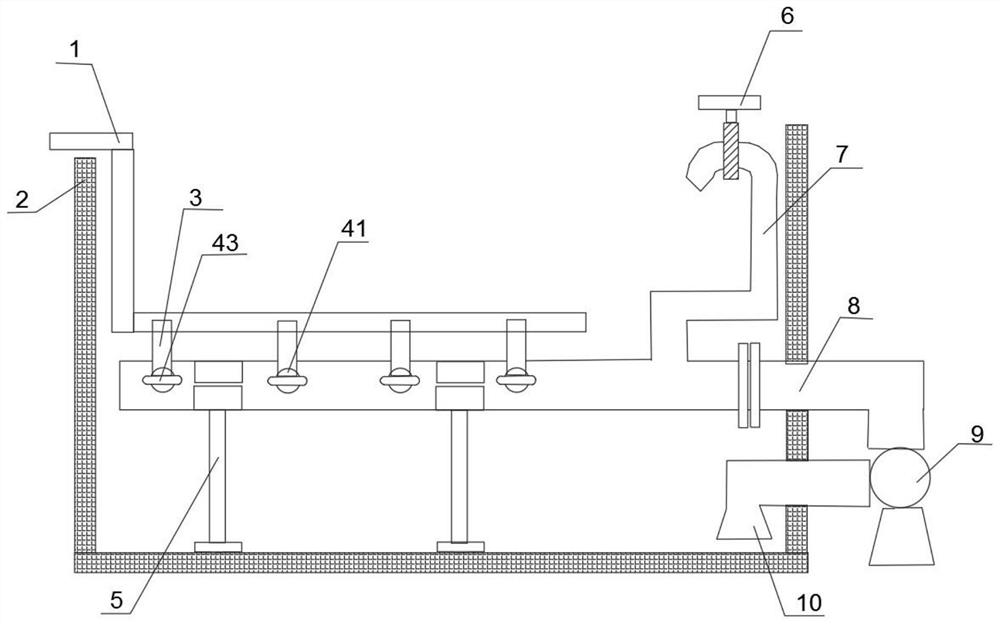

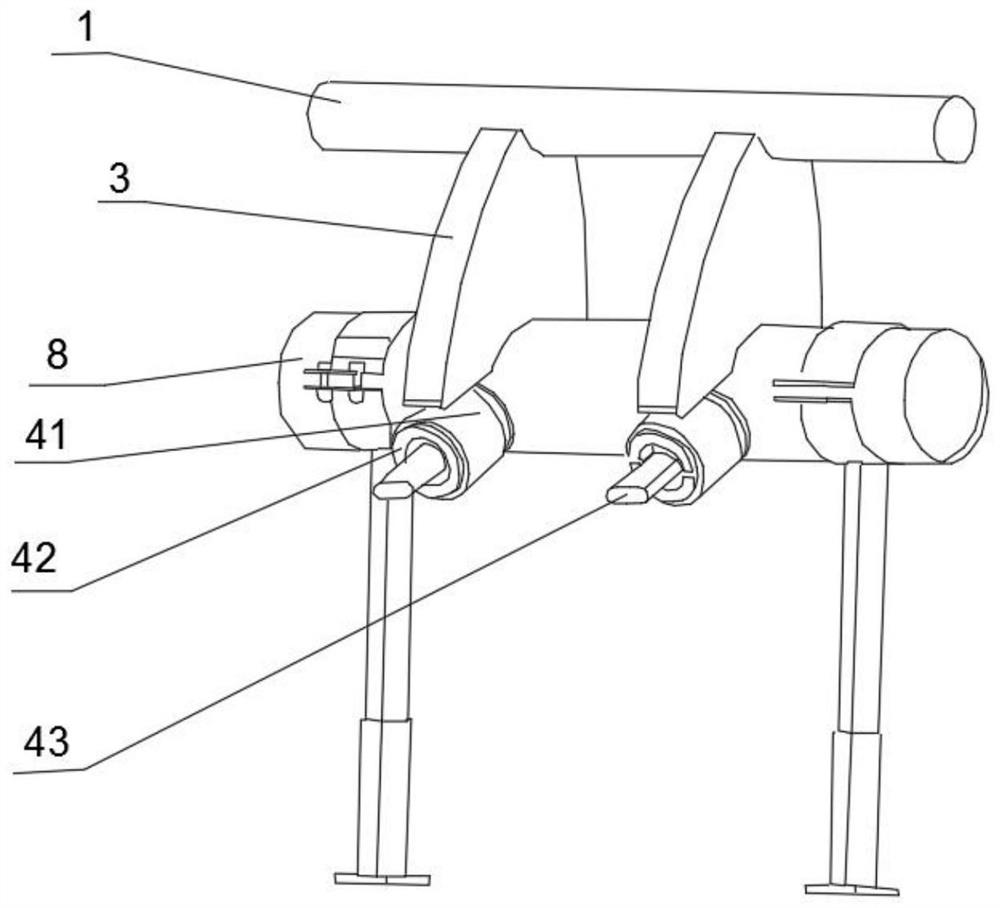

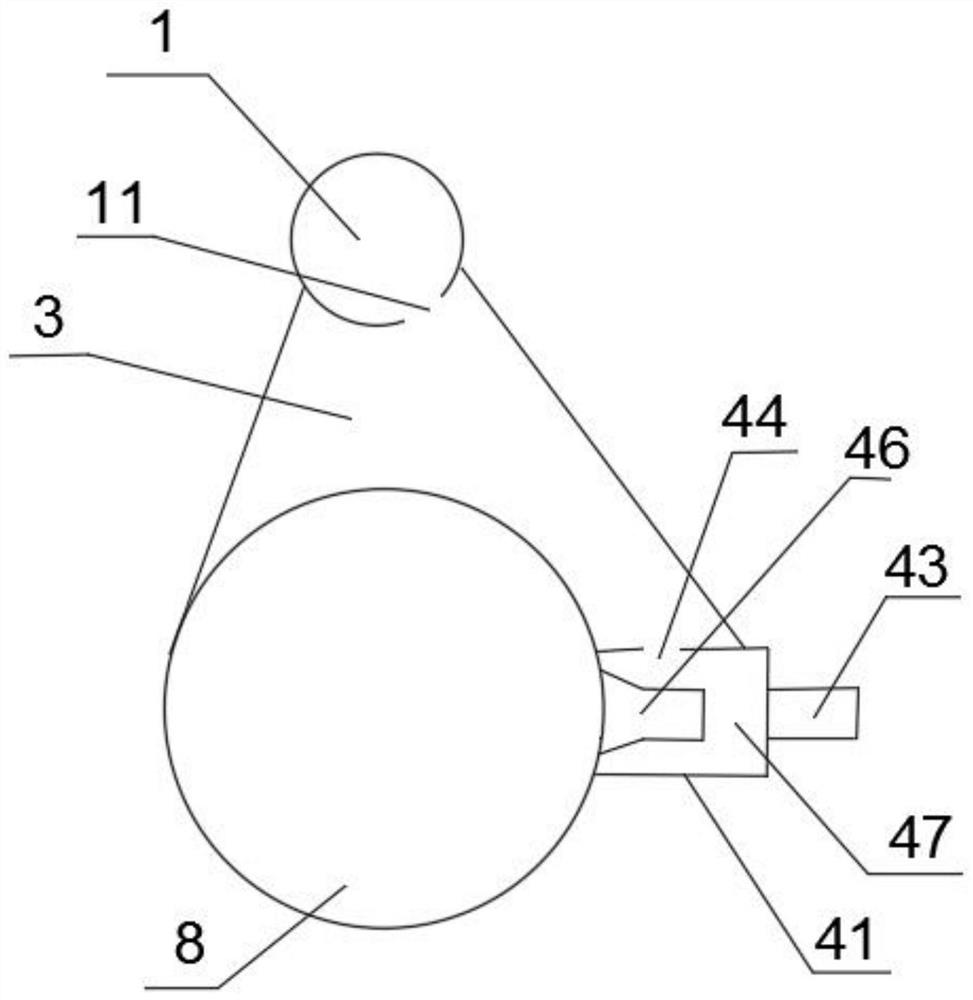

High-shear-force efficient jet aeration system and method

A high-efficiency jet flow and aeration system technology, applied in water aeration, chemical instruments and methods, sustainable biological treatment, etc., can solve the problem of enhancing liquid phase main turbulence and shear force, accelerating gas-liquid interface renewal, reducing liquid Film thickness and other issues, to achieve high total oxygen transfer efficiency, enhance turbulent flow and shear force, and save power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0072] For wastewater from a pharmaceutical factory, the theoretical oxygen demand AOR of the aeration tank is 225kgO2 / h, and the water depth of the aeration tank is 6.5m. The technological parameters of the new jet aerator, traditional jet aerator and microporous aeration using this technical solution are designed The comparison is as follows:

[0073]

[0074] Table 1: Comparison table of aeration process parameters of the new jet aerator, traditional jet aerator and microporous aerator of this technical solution;

[0075] From the above calculation and comparison, it can be seen that under the design condition of a water depth of 6.5m, the total power of the blower and the jet circulation pump of the new jet aerator system of this technical solution is basically the same as the power of the blower of the microporous aeration system, while the traditional jet aerator The total power of the air blower and the jet pump of the aeration system is about 25% higher than that of...

Embodiment example 2

[0078] For wastewater in a chemical industry park, the theoretical oxygen demand AOR of the aeration tank is 1000kgO2 / h, the water depth of the jet aeration tank is 8m, and the water depth of the microporous aeration tank is 6m for design;

[0079] The technical parameters of the new jet aerator, the traditional jet aerator and the microporous aeration are compared as follows:

[0080]

[0081] It can be seen from the above calculation and comparison that the jet aeration can operate well under the design condition of a water depth of 8m, and it is a simple and optimal economic water depth. When the water depth exceeds 8m, the selection range of the blower is small. In this implementation case, the total installed power of the blower and jet pump of the high-efficiency jet aeration system of this technical solution is 538kw, which is about 24.3% lower than the installed power of 711kw using a traditional jet aerator. The standard oxygen utilization rate increased from 32.3%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com