Electromagnetic induction heating aerosol forming device and application thereof

An electromagnetic induction heating and aerosol technology, applied in the direction of tobacco, etc., can solve the problems of difficult processing of small holes on the metal heating element and high cost, and achieve the effect of enhancing efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

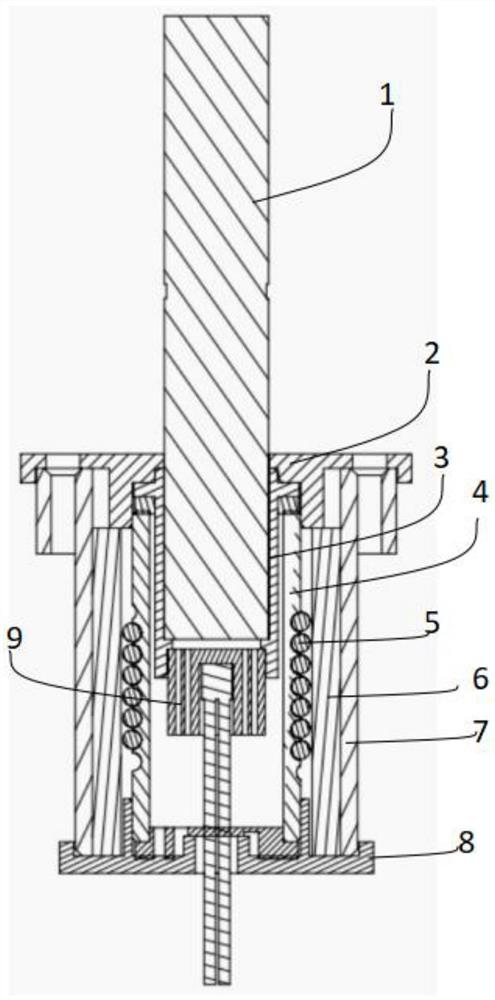

[0055] like figure 1 , an electromagnetic induction heating aerosol forming device, the aerosol forming device comprises: a casing 7, an upper cover 2, and a bottom cover 8. The shell 7 is provided with a heating element 9 , a cigarette cup 3 , a heat insulating element 6 , and an induction coil 5 . The aerosol forming device also includes: components such as a power supply and a control system, figure 1 not shown in.

[0056] Wherein, the shell 7 is clamped between the upper cover 2 and the bottom cover 8 . The tobacco cup 3 is arranged under the upper cover 2, and the tobacco cup 3 is used for accommodating cigarettes. The bottom of the smoke cup 3 has a cup hole.

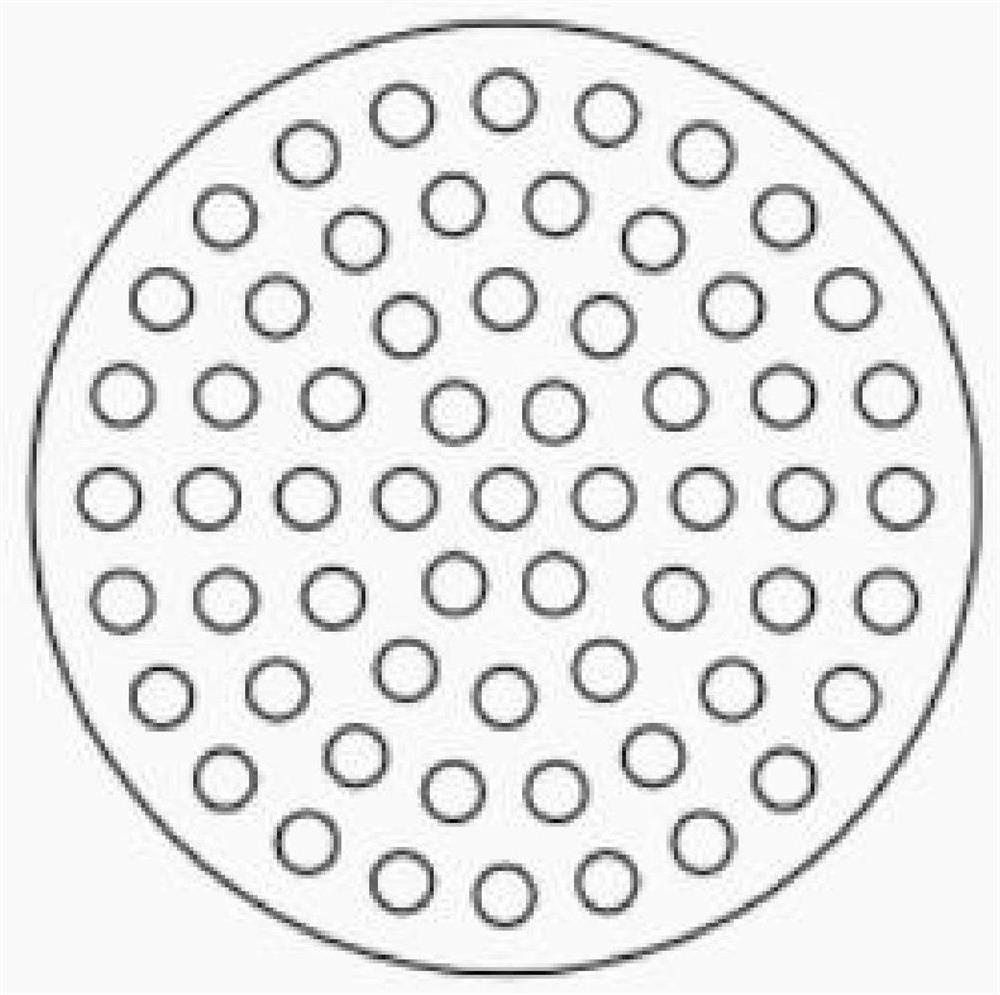

[0057] The heating element 9 contains ceramic material and soft magnetic material. In the first embodiment, the heating element 9 is an airflow heating element, which is clamped under the cup 3 , and the heating element 9 and the cup 3 are in airflow communication. In this embodiment, the heating element 9 ...

Embodiment 2

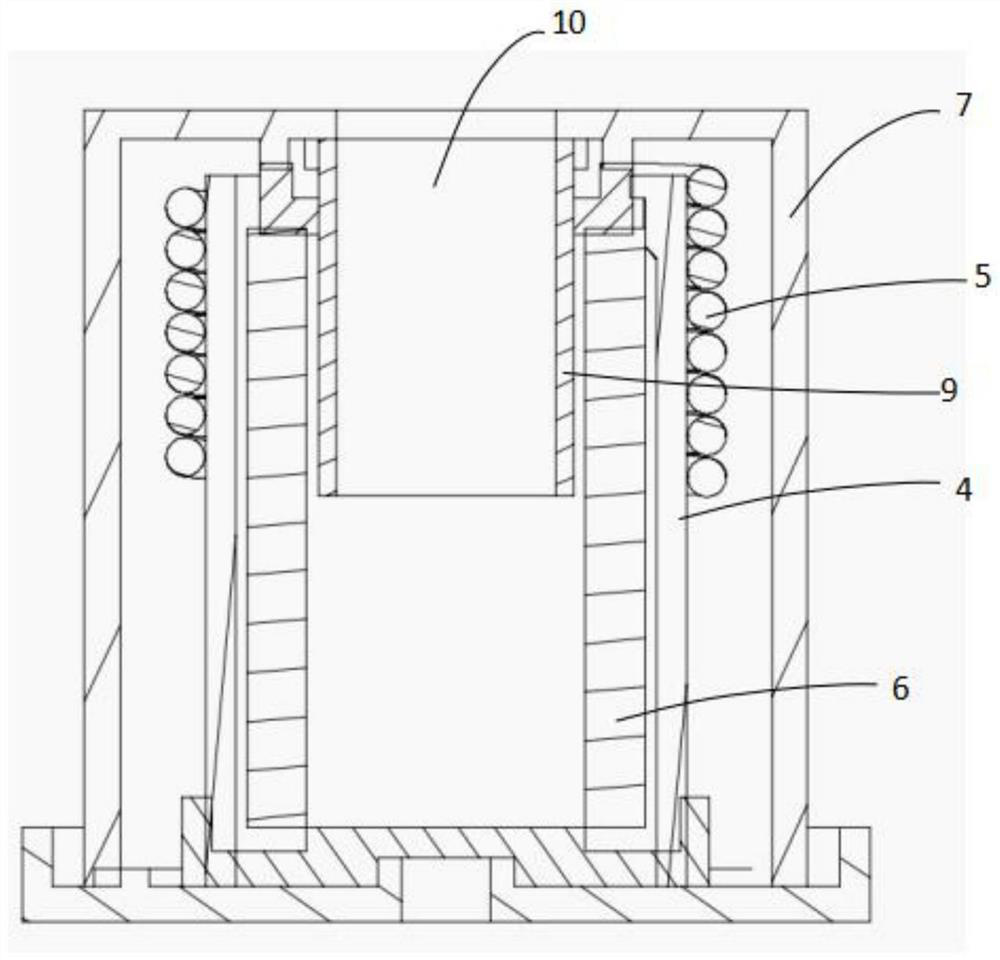

[0066] like figure 2 , an electromagnetic induction heating aerosol forming device, the aerosol forming device comprises: a housing 7 . The shell 7 is provided with a heating element 9 , a heat insulating element 6 , a coil fixing part 4 , and an induction coil 5 . The aerosol forming device also includes: components such as a power supply and a control system, figure 2 not shown in.

[0067] The difference from the aerosol forming device in Embodiment 1 is that in Embodiment 2, the heating element 9 is a circumferential heating pipe, which is arranged on the outer periphery of the cigarette accommodating chamber 10 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com