Cutter wear state evaluation method based on optimal characteristics and lion group optimization SVM (Support Vector Machine)

A tool wear and state evaluation technology, applied in the direction of manufacturing tools, metal processing machinery parts, measuring/indicating equipment, etc., can solve the problems of increased tool cost, decreased workpiece quality, and single feature value extraction, so as to improve production efficiency, The effect of small redundancy, improving evaluation speed and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings:

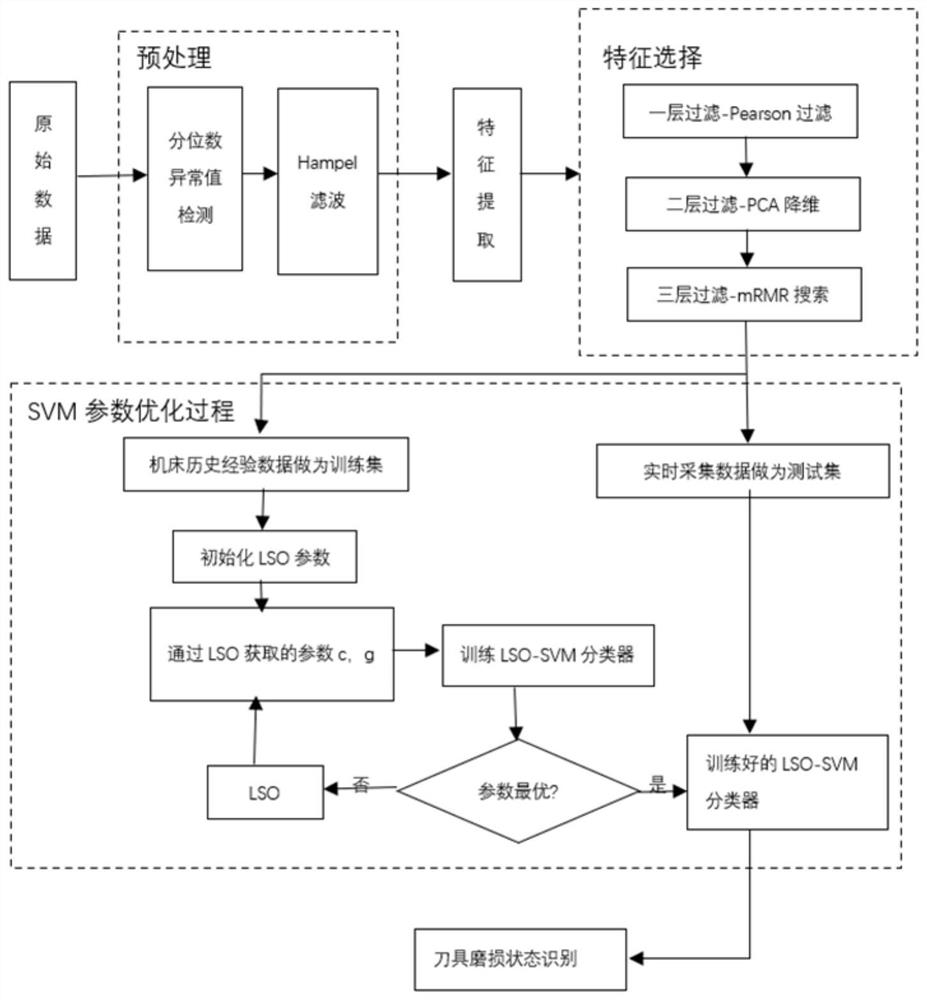

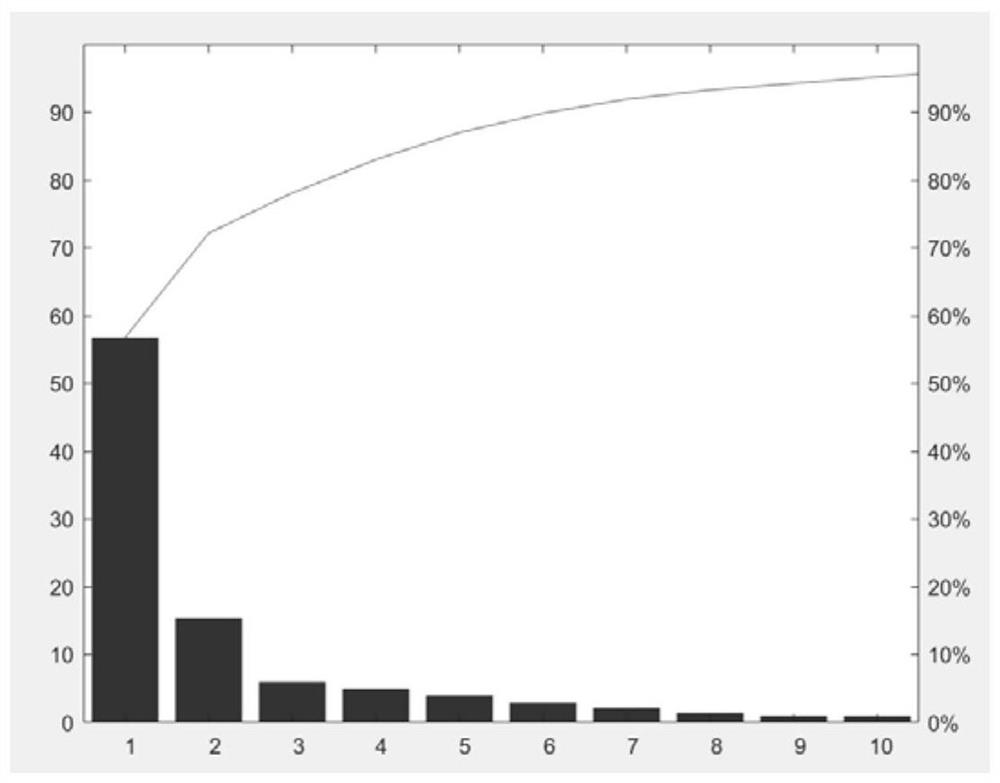

[0042] A method for evaluating the state of tool wear based on optimal features and lion group optimization SVM, comprising the following steps:

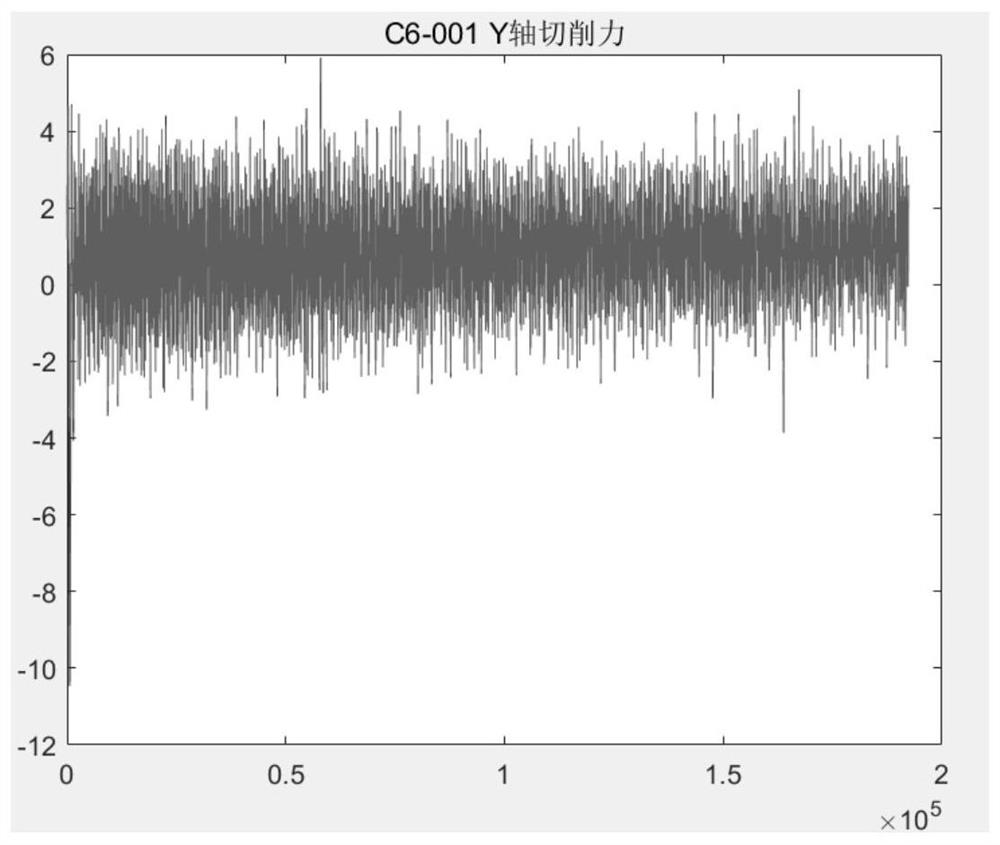

[0043] S1. Data preprocessing: Data preprocessing is performed on the CNC machine tool experience data set. The CNC machine tool experience data set includes sensor data and tool wear data of 7 channels. The sensor data of the 7 channels are in the x, y, and z directions respectively. Cutting force, vibration and acoustic emission signals in x, y, z directions;

[0044] S1.1, quantile outlier detection: first arrange all the values from small to large, and then divide them into 4 parts, and then set the upper quartile Q1, median Q2 and lower quartile Q3 in sequence, then Interquartile range IQR=Q3-Q1, then the basis for judging the abnormal value is the value greater than Q1+1.5×IRQ or less than Q3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com