Target-free lifting appliance positioning method for closed-loop control of automatic travelling crane

A technology of closed-loop control and positioning method, which is applied in the direction of comprehensive factory control, load hanging components, transportation and packaging, etc., and can solve problems such as difficult promotion, unsuitable installation conditions, discomfort, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

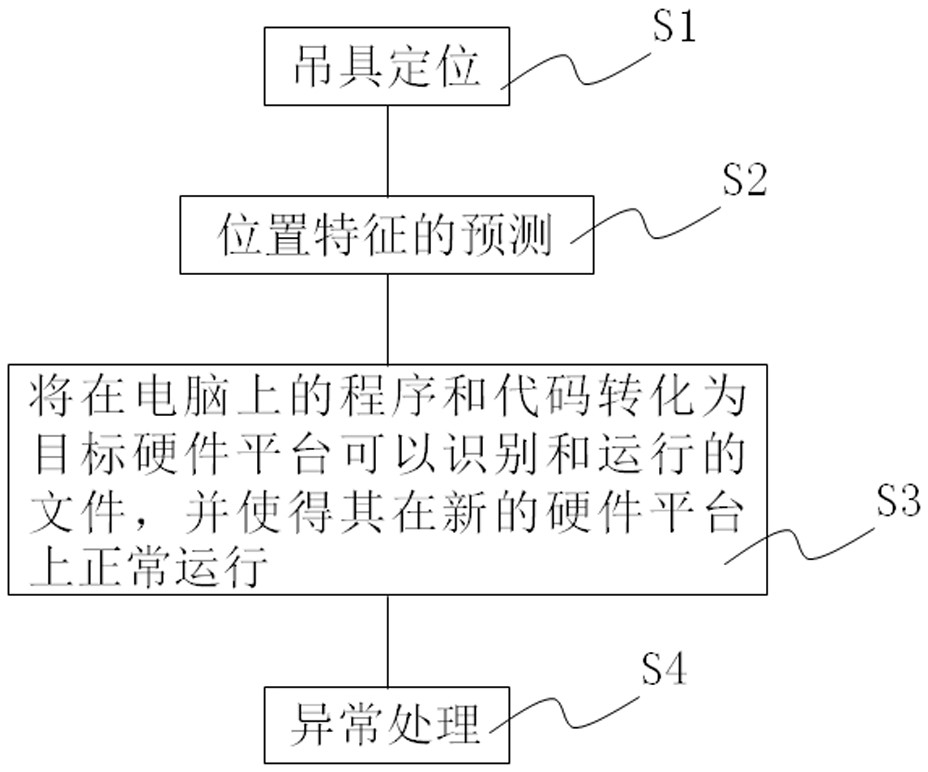

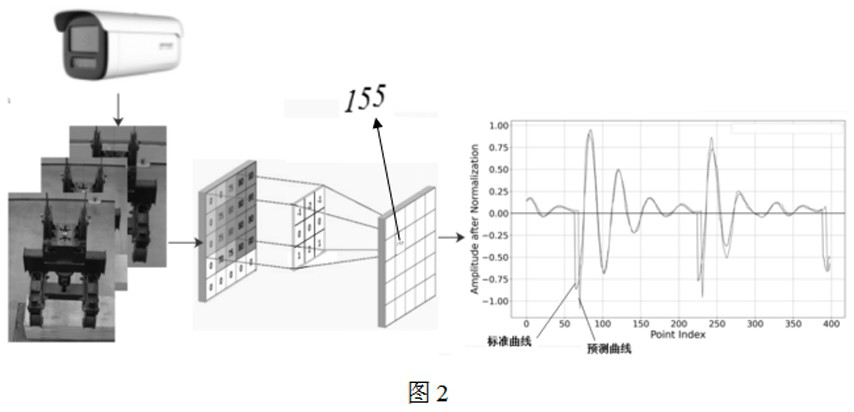

[0021] see Figure 1 to Figure 2 , the present invention provides a targetless spreader positioning method for automatic driving closed-loop control, comprising the following steps,

[0022] S1: Spreader positioning.

[0023] Since the spreader is diverse and the working conditions are also diverse, it is necessary to obtain the position characteristics of the spreader stably and reliably.

[0024] Specifically, the following steps are adopted to obtain the position features of the spreader, and step S1 further includes step S11: using the pulley...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com