Steel structure building surface mounting structure

A surface-mounted, steel-structured technology that is applied to building components, building structures, buildings, etc., and can solve problems such as difficulty in assembly and discrepancies between the actual assembly effect and the design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The following is attached Figure 1-7 The application is described in further detail.

[0052] The embodiment of the present application discloses a surface installation structure of a steel structure building.

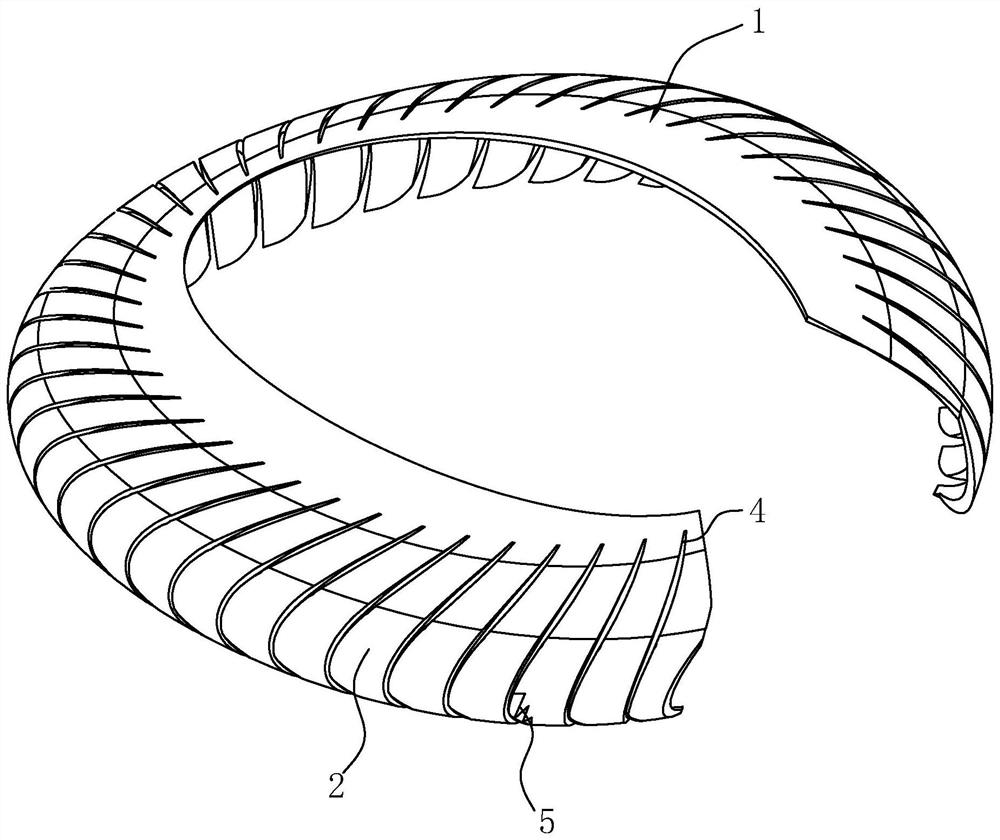

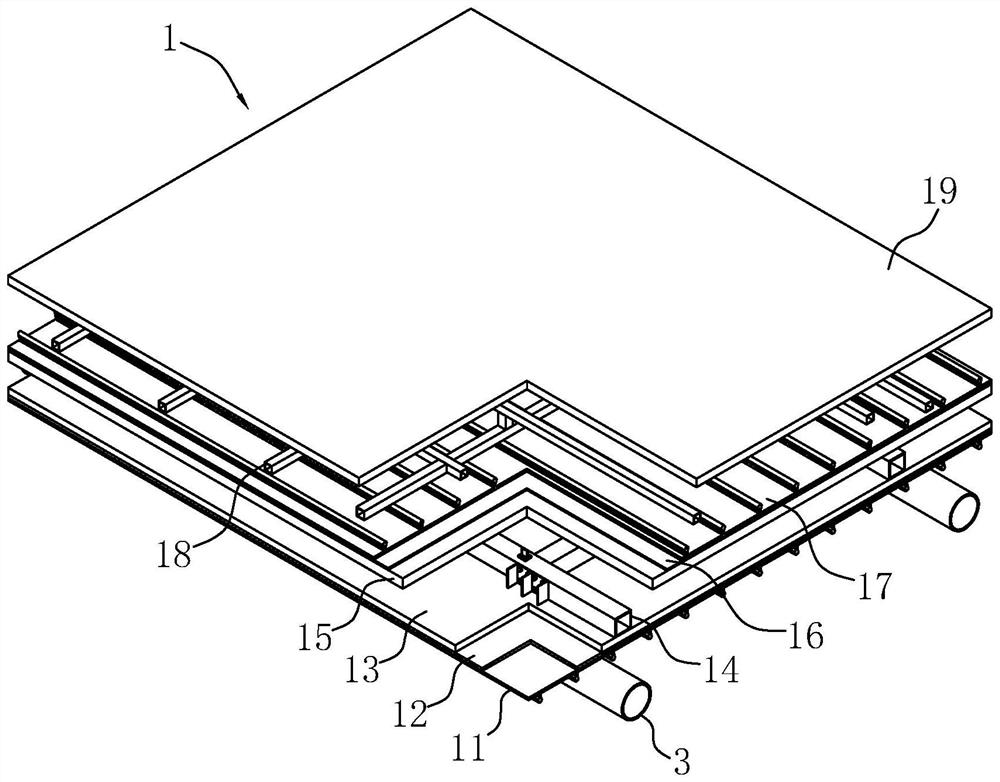

[0053] refer to figure 1 and figure 2 The surface installation structure of the steel structure building includes a steel frame 3, a roof 1 installed on the top of the steel frame 3, and a curtain wall 2 installed on the circumferential side wall of the steel frame 3. A gutter 4 for drainage is installed on the roof 1, and the curtain wall 2 is equipped with the curved curtain mechanism 5 that is used for moulding.

[0054] refer to figure 2 and image 3 , the part of the steel frame 3 located on the roof 1 is similar to a planar structure as a whole, and the roof 1 is partly an arc-shaped curved surface.

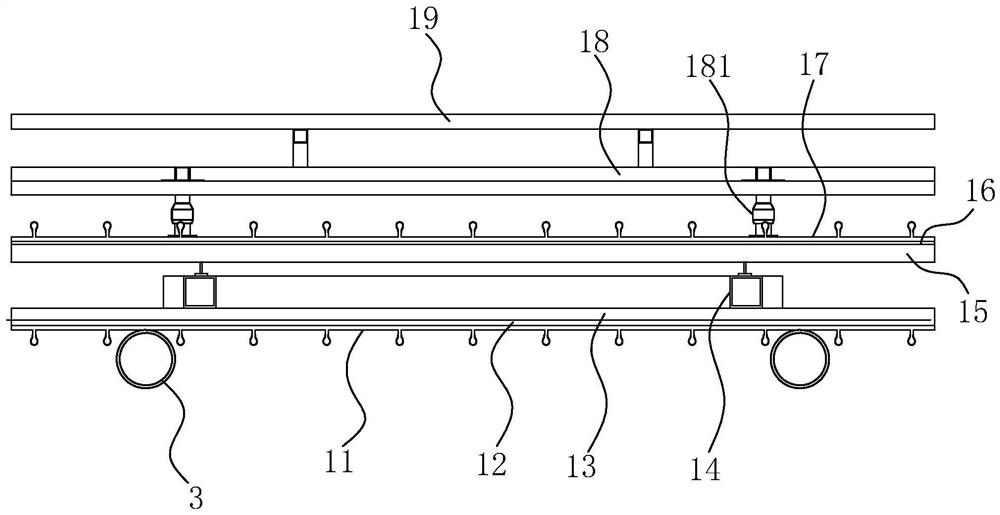

[0055] The roof 1 is supported and fixed on the steel frame 3. The roof 1 includes a bottom plate 11, a middle support plate 17 and a top plate 19 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Chord length | aaaaa | aaaaa |

| Bending radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com