Assembly type wavy perforated profiled aluminum plate mounting device

An installation device and wave-shaped technology, which is applied to building components, covering/lining, walls, etc., can solve the problems of large aluminum plate, affecting viewing, easy deformation, etc., and achieve high installation efficiency, good appearance and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

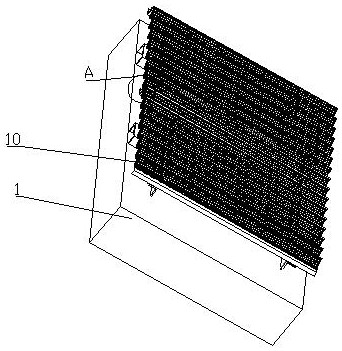

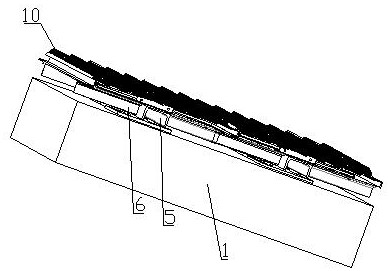

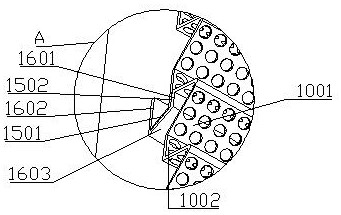

[0028] see Figure 1 to Figure 6 , the present invention provides an assembly type corrugated perforated aluminum plate installation device, which includes two sets of galvanized steel plates symmetrical to each other, each galvanized steel plate set includes two symmetrical galvanized steel plates 3, which run through the galvanized steel plates 3 The four corners of the side wall are provided with expansion bolts 2, and the galvanized steel sheets 3 are all fixed on the wall surface 1 through the expansion bolts 2, and both sides of the galvanized steel sheet 3 are symmetrically provided with galvanized angle steel-4, which are located in the same group of two A galvanized channel steel 5 is arranged between the galvanized steel plates 3, and the galvanized channel steel 5 is located between two galvanized angle steels-4, and galvanized angle steels are fixedly arranged on two opposite side walls of the galvanized steel channel steel 5 2. 6. There are symmetrical L-shaped pe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap