Improved structure of axial-flow type high-temperature smoke exhaust fan

A smoke exhaust fan, axial flow technology, applied to the components, heating methods, ventilation systems, etc. of the pumping device for elastic fluids, can solve the problems of high temperature and vulnerability of the fan, achieve stable water flow temperature, and avoid smoke Air overheating damages equipment and reduces difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

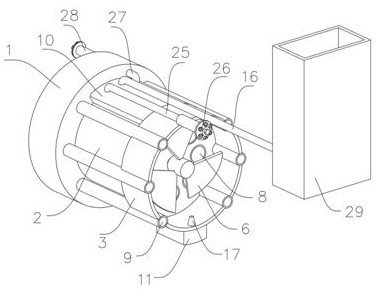

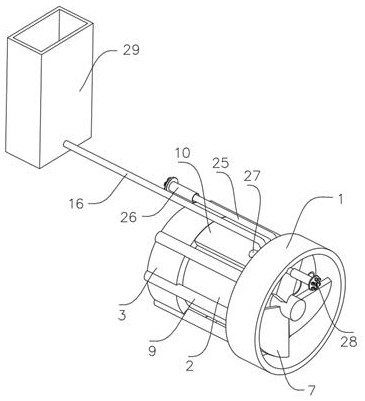

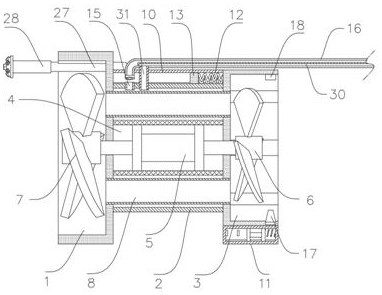

[0027] refer to Figure 1-7 , an improved structure of an axial-flow high-temperature smoke exhaust fan, including a front box 1, a pipe sleeve 2 fixed to the side wall of the front box 1, a rear box 3 fixed to the end of the pipe sleeve 2, the front box 1 and the rear box 3 The side walls of the machine cover 4 are fixed together, the inner wall of the machine cover 4 is fixed with a motor 5, the motor 5 is a double-headed motor, and the two output shafts of the motor 5 are respectively fixed with a rear blade 6 and a front blade 7, and the rear blade 6 and front fan blades 7 are respectively located in the rear box 3 and the front box 1, the output shaft of the motor 5 is sealed and penetrates through the rotation connection with the front box 1 and the rear box 3 to avoid water leakage, and the side wall of the front box 1 is inserted through and connected with the rear box. A plurality of inner through pipes 8 and outer through pipes 9 connected inside the box 3, the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com