Device and method for measuring high-precision mounting flatness of cable saddle of suspension bridge

A measuring device and flatness technology, applied in the direction of measuring device, mechanical roughness/irregularity measurement, using fluid device, etc., can solve difficult to achieve construction processing, installation accuracy, measurement accuracy can not meet the requirements, and measurement accuracy is low and other problems, to achieve the effect of improving measurement accuracy and efficiency, low installation and manufacturing costs, and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with implementation examples and with reference to the accompanying drawings.

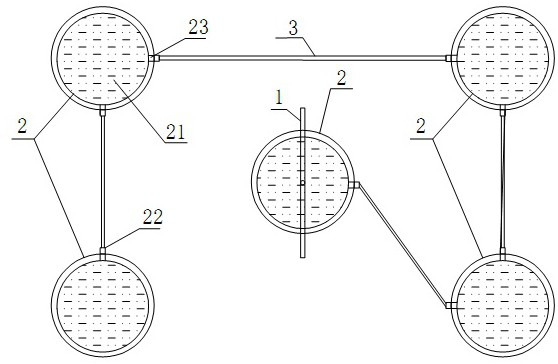

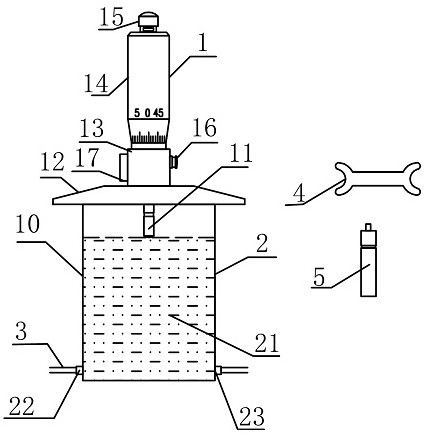

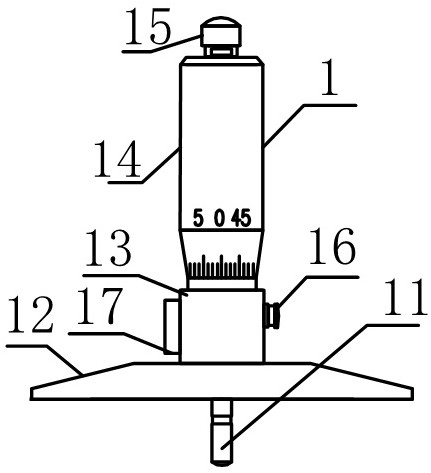

[0028] A high-precision installation flatness measurement device for suspension bridge saddles, including a depth micrometer 1, a stainless steel cup 2 and a connecting conduit 3, the depth micrometer 1 is composed of a measuring probe 11, a depth micrometer base 12, a fixed sleeve 13, and a micrometer cylinder 14 , a force measuring device 15, a locking device 16, and an electronic reading display device 17. Five stainless steel cups 2 of the same size and height are respectively placed at the four corners and the center of the top surface of the cable saddle grid. The bottom of the side wall is provided with a water inlet and outlet hole 23, and a connection buckle 22 is arranged on the outside of the water inlet and outlet hole 23. The connecting conduit 3 starts from the stainless steel cup 2 in the center and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com