Hypersonic aircraft pulsating pressure test sensor optimization arrangement method

A hypersonic, pulsating pressure technology, used in aerodynamic testing, testing of machine/structural components, instruments, etc., can solve the problems of unreasonable sensor arrangement, complicated economic cost pulsating pressure test data, etc., to reduce economic costs, Reduce the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

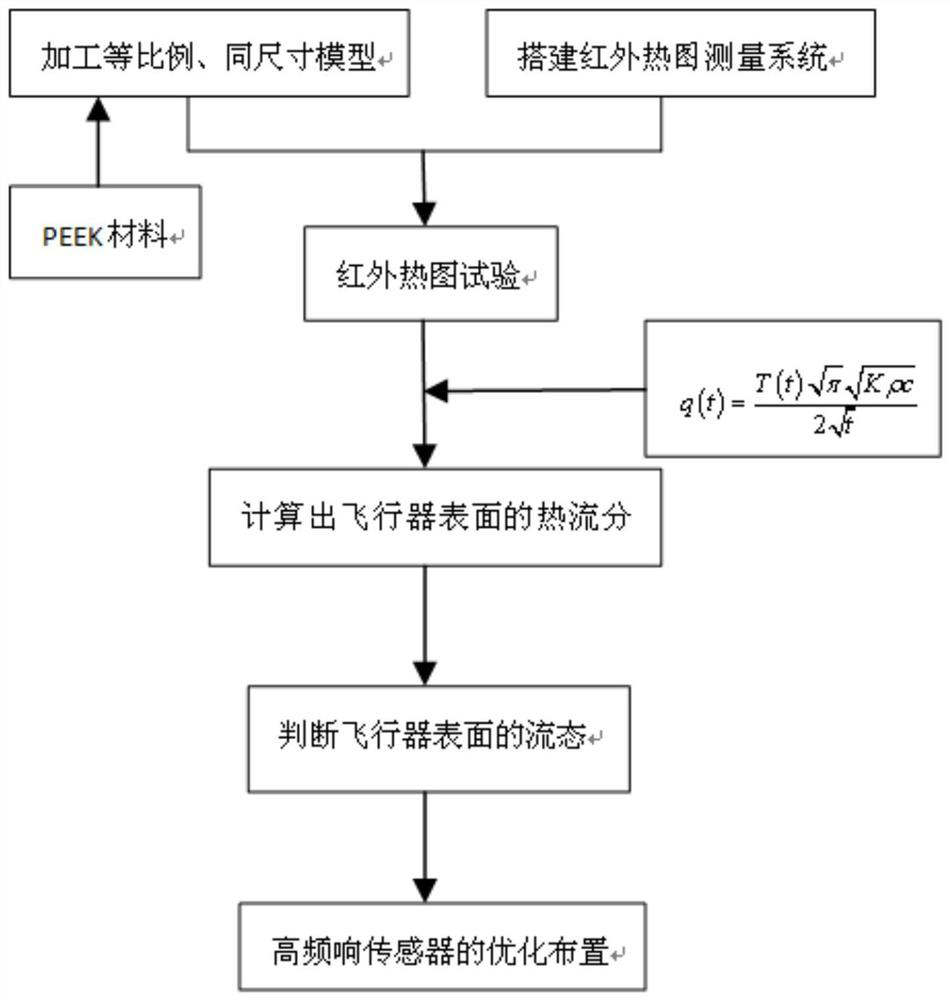

[0033] Such as figure 1 as shown,

[0034] This embodiment provides a method for optimizing the arrangement of hypersonic vehicle pulsation pressure test sensors, including the following steps:

[0035] Step 1, processing an aircraft model equal in proportion to the pulsation pressure test aircraft model and the same size as the model for the infrared heat map test;

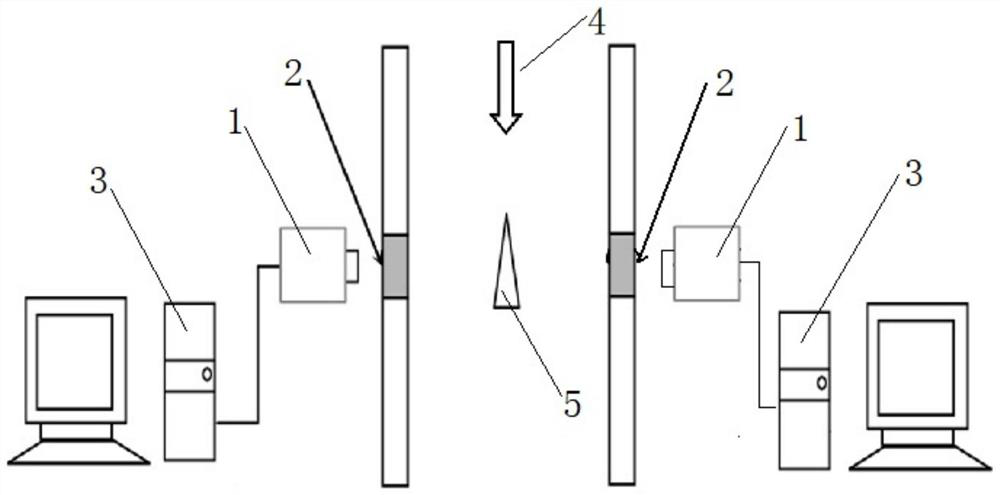

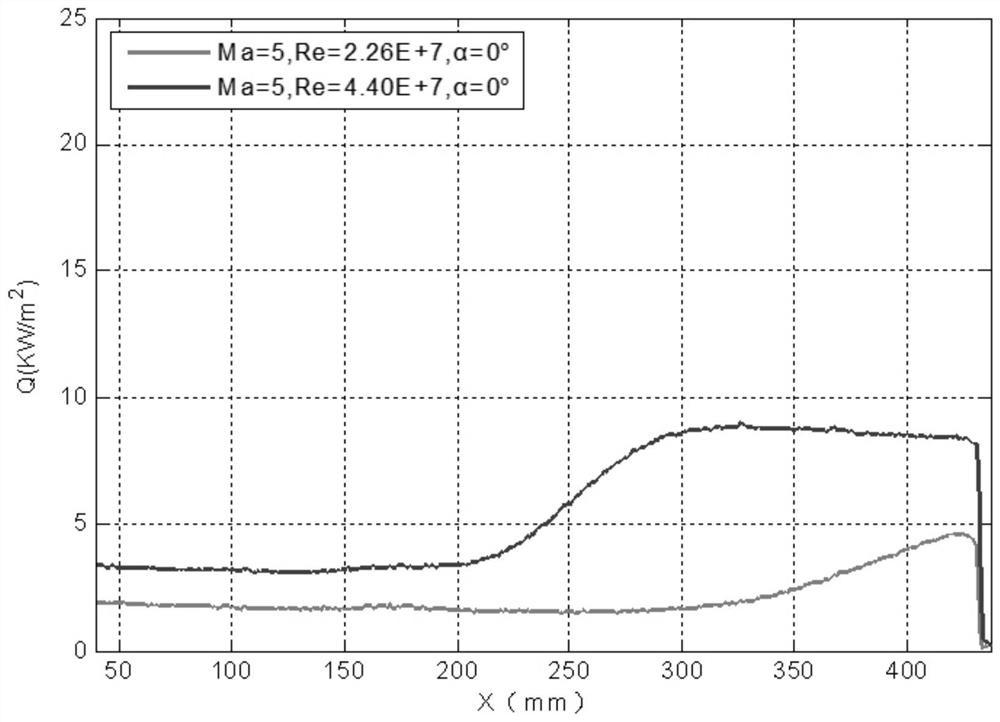

[0036] In this embodiment, the hypersonic wind tunnel test based on infrared heat map technology is to guide the optimal arrangement of high-frequency sensors for pulsation pressure tests. In particular, the principle of infrared heat map technology is to use the principle of thermal radiation to detect the radiation of objects To obtain the temperature of the surface of the model, it is required that the infrared test model material be selected from a specific PEEK material, which has high emissivity, is easy to process, and has stable thermal and physical parameters. Therefore, the present invention adopts th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com