Cutting device for aviation aluminum alloy plate machining

A technology of aluminum alloy sheet and cutting device, which is applied in shearing device, metal processing equipment, accessory device of shearing machine, etc., can solve the problem of low processing efficiency of aviation aluminum alloy sheet, processing loss of aviation aluminum alloy sheet, and waste of time and energy. and other problems to achieve the effect of reducing manual workload, improving cutting efficiency, and avoiding the deviation of the cutting knife

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The principles and features of the present invention will be described below with reference to the accompanying drawings, and the examples are only used to explain the invention, but not to limit the scope of the invention.

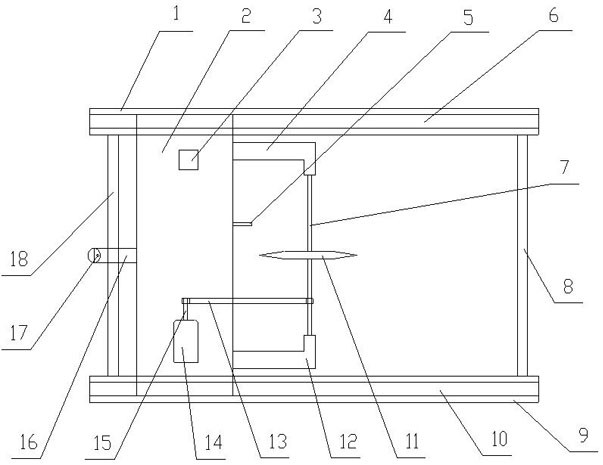

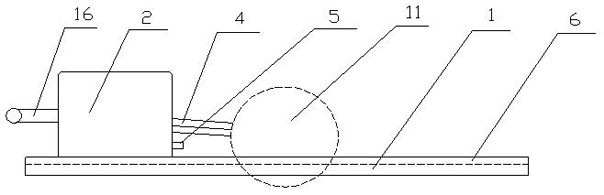

[0013] A cutting device for aerospace aluminum alloy sheet processing, comprising a base rail groove 1, a body 2, a controller 3, a rotating shaft seat 4, an infrared probe 5, a sliding rail 6, a rotating shaft 7, a support rod 8, a base rail Slot two 9, slide rail two 10, cutting knife 11, shaft seat two 12, belt 13, cutting motor 14, motor shaft 15, operating handle 16, switch 17 and support rod two 18, base rail groove one 1, support rod one 8. The base rail groove two 9 and the support rod two 18 are installed to form the base. The lower ends of the body 2 are provided with slide rail one 6 and slide rail two 10 corresponding to the base rail groove one 1 and the base rail groove two 9, and the rotating shaft seat one 4 and the rotating shaft s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com