Steel guide wheel for slicer

A slicer and guide wheel technology, applied in the direction of working accessories, fine working devices, stone processing equipment, etc., can solve the problems of short service life of guide wheels, no research on guide wheels, and affect product quality, so as to reduce production and processing Cost, improve product processing quality, improve the effect of precision and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

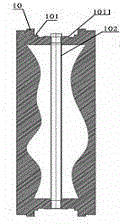

[0013] Such as figure 1 A rigid body guide wheel for a slicer shown includes a guide wheel main body 10 and a bearing bush hole 101, the guide wheel main body 10 is a cylindrical structure, the length of the guide wheel main body is 1060mm±0.3mm, and the guide wheel main body diameter is 330mm± 0.2mm; both ends of the main body of the guide wheel are respectively provided with a bearing hole 101 and a guide tube 102, and the guide tube 102 passes through the guide wheel to reach the bottom of the bearing hole at both ends.

[0014] As mentioned above, the maximum diameter of the bearing bush hole 101 at both ends of the main body of the guide wheel is 180mm-0.02mm, and the minimum diameter is 180mm-0.05mm.

[0015] The guide wheel is made of No. 45 steel material, and the overall mass is 193KG±2KG.

[0016] The concentricity of bearing bush holes at both ends of the guide wheel is ≤0.01mm, and the dynamic balance of the guide wheel is ≤8G.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com