Linear cutting machining method for whole-circumference outer contour metal sheet part

A metal thin plate and processing method technology, applied in the field of mechanical processing, can solve problems such as falling, joint marks, etc., and achieve the effects of improving the pass rate, improving processing efficiency, and simplifying the processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The wire cutting process of the entire circumference outer contour metal sheet part includes the following steps:

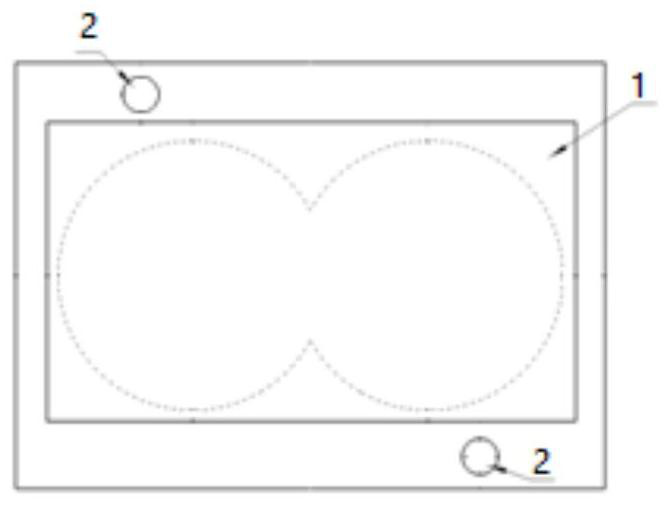

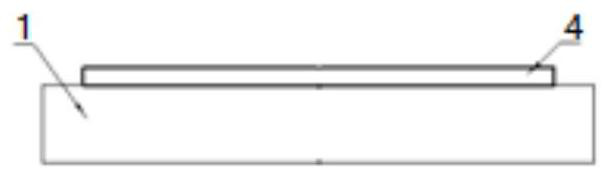

[0031] 1) Secure the machining substrate 1 to the wire cutting table, find the normal processing substrate 1, and the metal sheet 4 to be processed is fixed to the processing substrate 1, and the positioning hole to which the metal sheet 4 to be processed and the positioning hole of the processing substrate 1 is coincident;

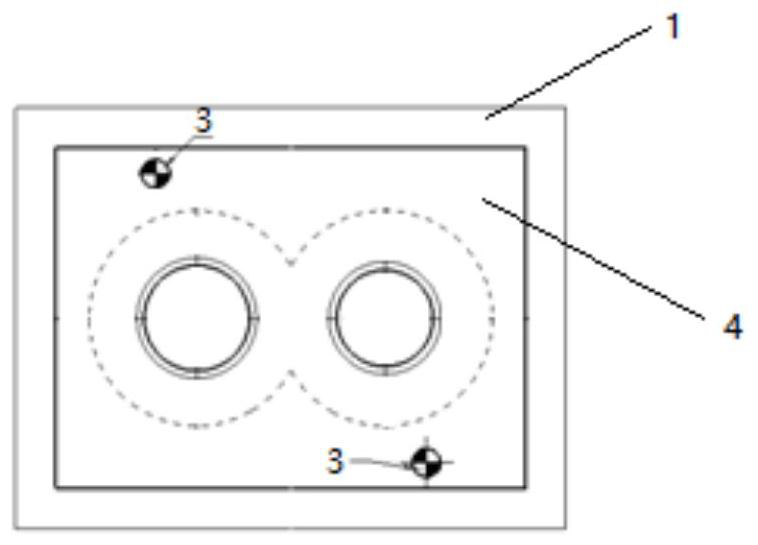

[0032] 2) See Figure 4 The first cut of partial circumferential contour is performed on the metal sheet 4 in the metal sheet 4 according to the third wire wire; the first cut is to cut the metal sheet entire circumference outer fluorescence first;

[0033] 3) See Figure 5 The first cutting of the circumferential outer contour of the first cut is coupled to the body of the metal sheet 4 to be processed, and the body to be processed the metal sheet 4 refers to a portion of the initial cooperation with the cut circumference outer contour, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com