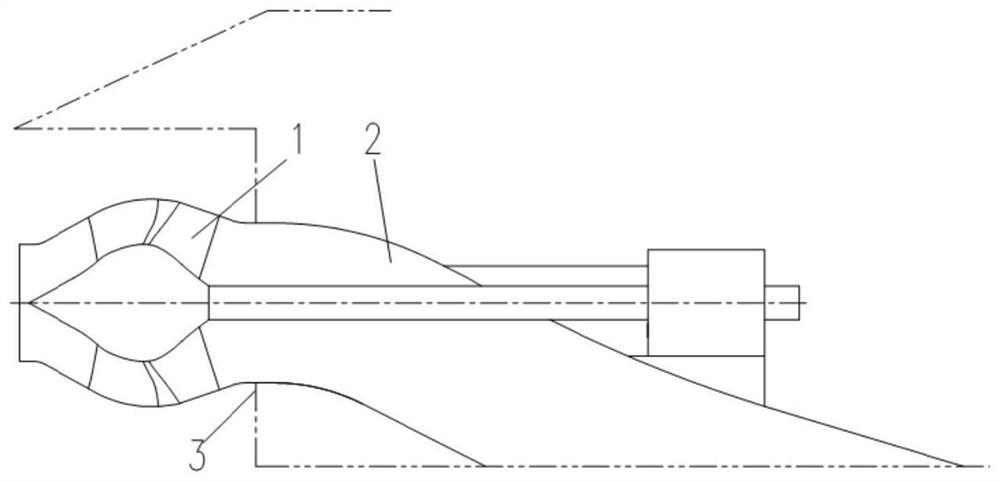

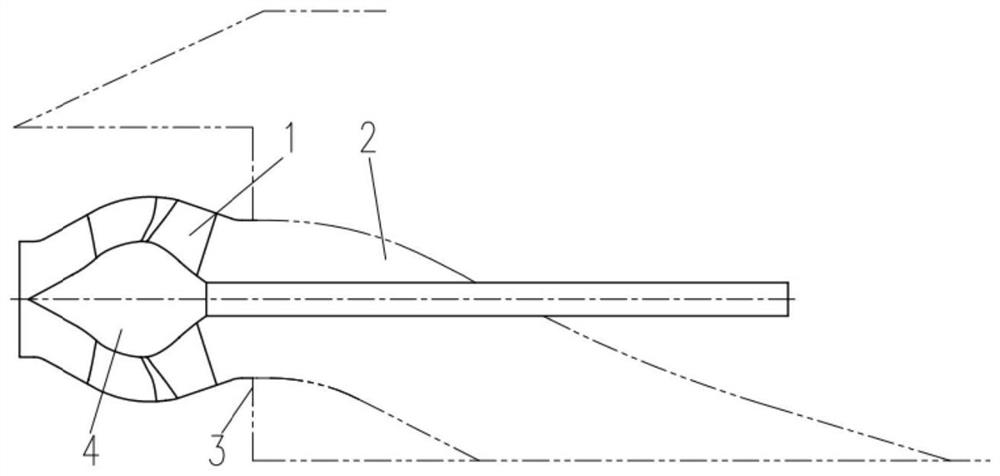

Self-circulation heat dissipation thrust bearing cavity structure of small and medium-sized water-jet thruster

A technology of water jet propulsion and thrust bearing, which is applied in ship propulsion, propulsion components, transmission devices with synchronous propulsion components, etc. Effect of heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the application clearer and easier to understand, preferred embodiments are described in detail below with accompanying drawings.

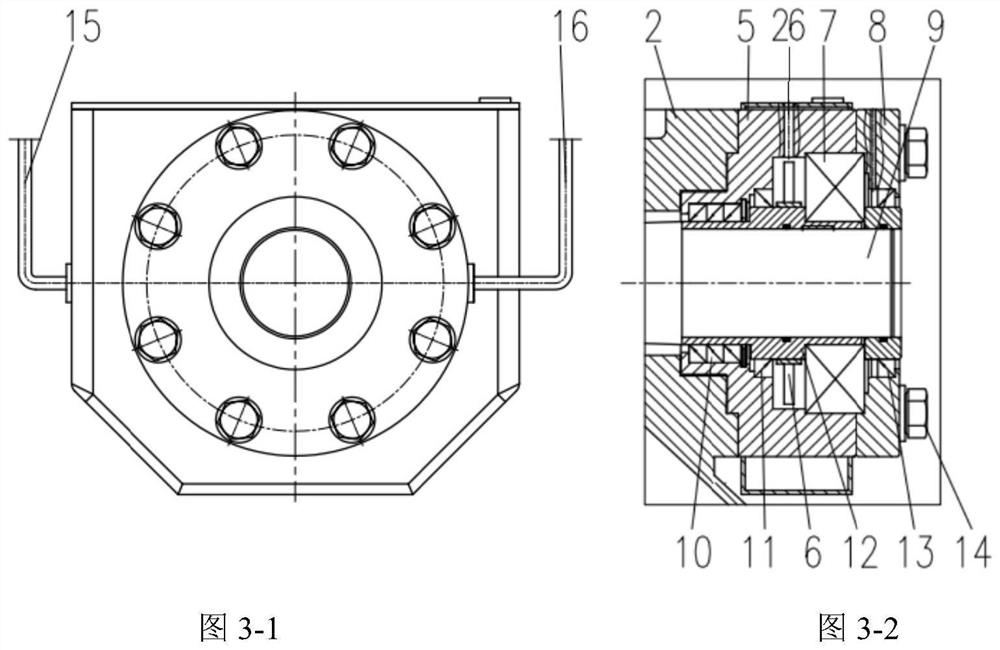

[0031] What this embodiment provides is the thrust bearing cavity structure of a small and medium-sized water jet propeller that can dissipate heat through self-circulation, (the right side referred to in this application refers to the direction of the source of the water flow, and the left side refers to the direction of the water jet after the reference), such as image 3 , Figure 4As shown, the heat dissipation bearing box 5 includes a bearing box 17 and a heat dissipation jacket 18, the heat dissipation jacket 18 is welded on the outer edge of the bearing box 17 or cast as one with the bearing box 17, and an outer cavity is formed between the heat dissipation jacket 18 and the bearing box 17 , the inside of the bearing box 17 is an inner cavity, the impeller shaft 9 is arranged in the inner cavity of the bearing box 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com