Connection type movable box for logistics

A technology of connecting and moving boxes, which is applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc. It can solve the problems of sideways turning of moving boxes, dumping of internal materials, material damage, etc., and achieve the effect of avoiding connection breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

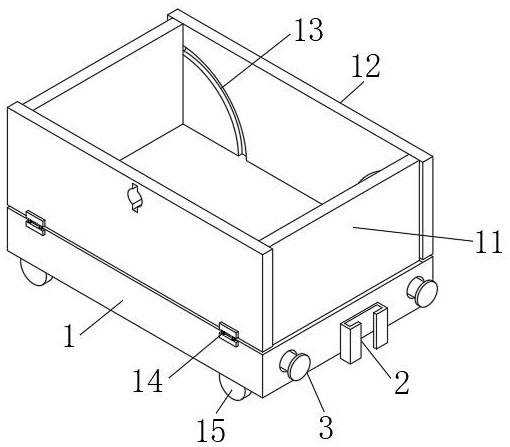

[0033]A connected mobile box for logistics, including a support base 1, the surface of the support base 1 is movably connected with a baffle plate 11 and a guard plate 12, the surface of the guard plate 12 is provided with a chute 13, and the outer surface of the support base 1 is fixed An adjustment block 14 is connected, the bottom end of the support base 1 is movably connected with a runner 15, the surface of the support base 1 is provided with an anti-dumping mechanism, the anti-dumping mechanism includes a connection groove 2, and the connection groove 2 is movably connected on the surface of the support base 1, The surface of the supporting base 1 is movably connected with a connecting block 21, the side of the connecting groove 2 close to the supporting base 1 is fixedly connected with a connecting rod 22, and the end of the connecting rod 22 away from the connecting groove 2 is fixedly connected with an adjusting rod 23, and the surface of the adjusting rod 23 is fixed. ...

Embodiment 2

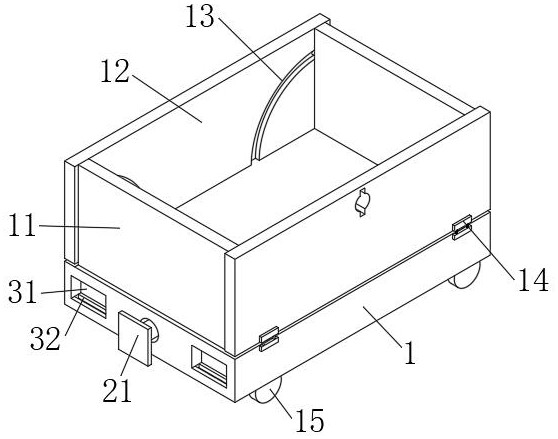

[0039] The same features of this embodiment and Embodiment 1 will not be repeated. The difference between this embodiment and Embodiment 1 is that in this embodiment, the support base 1 is provided with a protective mechanism, and the protective mechanism includes a telescopic rod 3, and the telescopic rod 3 Fixedly connected to the inner side of the support base 1, the surface of the support base 1 is provided with a movable groove 31, the inner wall of the movable groove 31 is provided with a limit groove 32, and the side of the connecting groove 2 close to the connecting rod 22 is fixedly connected with a rubber tube 33, the connecting groove The surface of 2 is fixedly connected with inserting rod 34, and the surface of inserting rod 34 is fixedly connected with retaining plate 35, and the inner side of connecting rod 22 is movably connected with limiting plate 36, and the surface of limiting plate 36 is fixedly connected with resisting spring 37, on telescopic rod 3 Under ...

Embodiment 3

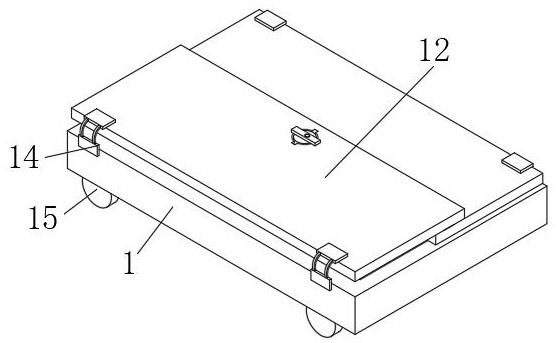

[0042] The same features of this embodiment and Embodiment 1 will not be described in detail. The difference between this embodiment and Embodiment 1 is that in this embodiment, the surface of the runner 15 is provided with a support mechanism. 4. Fixedly connected to one end of the runner 15 close to the support rod 28, the surface of the runner 15 is fixedly connected with a support leg 41, the surface of the support leg 41 is provided with a moving groove 42, and the inner side of the moving groove 42 is slidably connected with a pull rod 43. The surface of 4 is fixedly connected with clamping rod 44, and the surface of support rod 28 is provided with draw-in groove 45, and the outer surface of clamping rod 44 is slidably connected with ball 46, and the surface of ball 46 is fixedly connected with extension spring 47, and the surface of ball 46 is fixedly connected with extension spring 47. One end near the clamping rod 44 is fixedly connected with a stay cord 48, and throug...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap