An automatic installation dustproof ring device

An automatic installation and anti-dust ring technology, which is applied in the field of parts processing, can solve the problems of long time-consuming and low work efficiency, and achieve the effects of easy transportation, improved installation efficiency, and improved assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

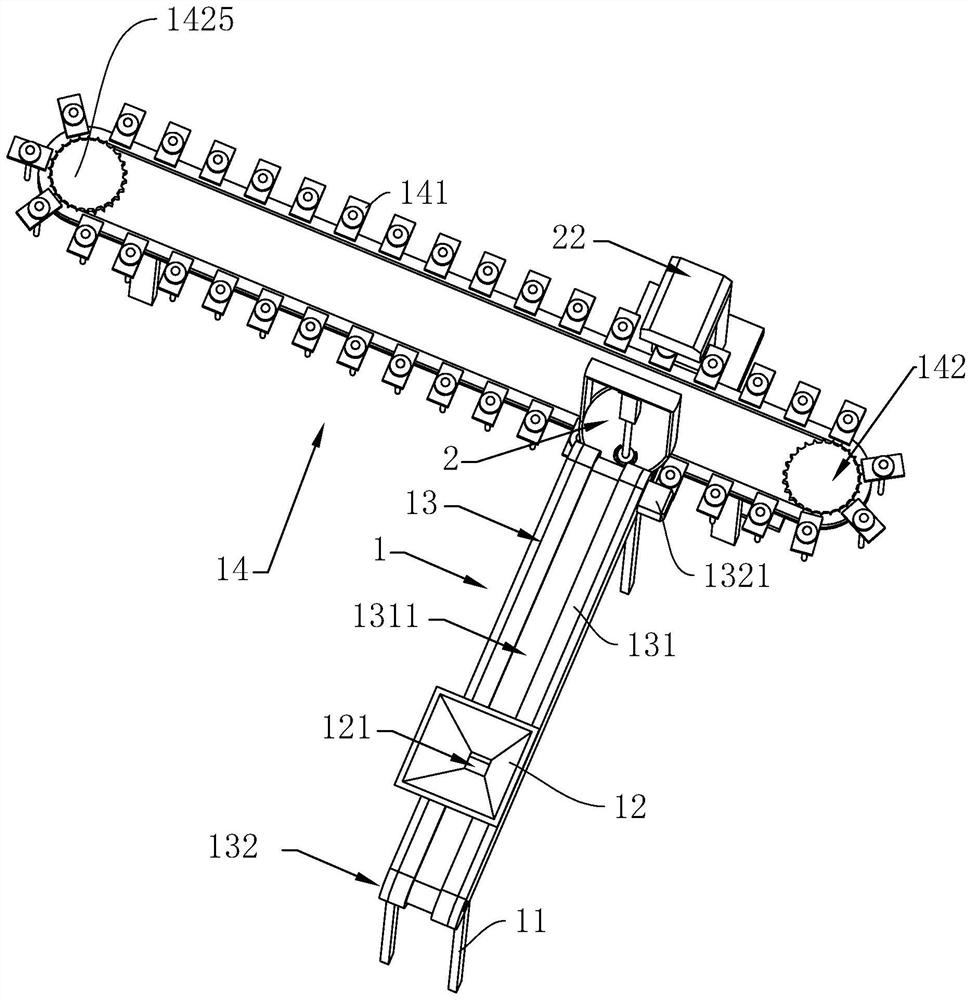

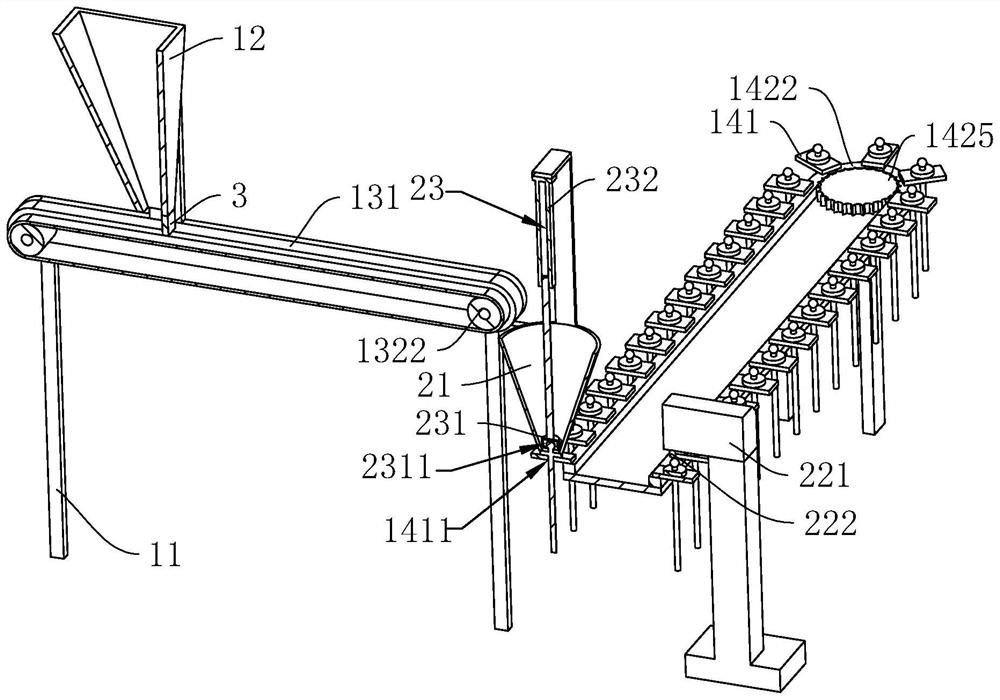

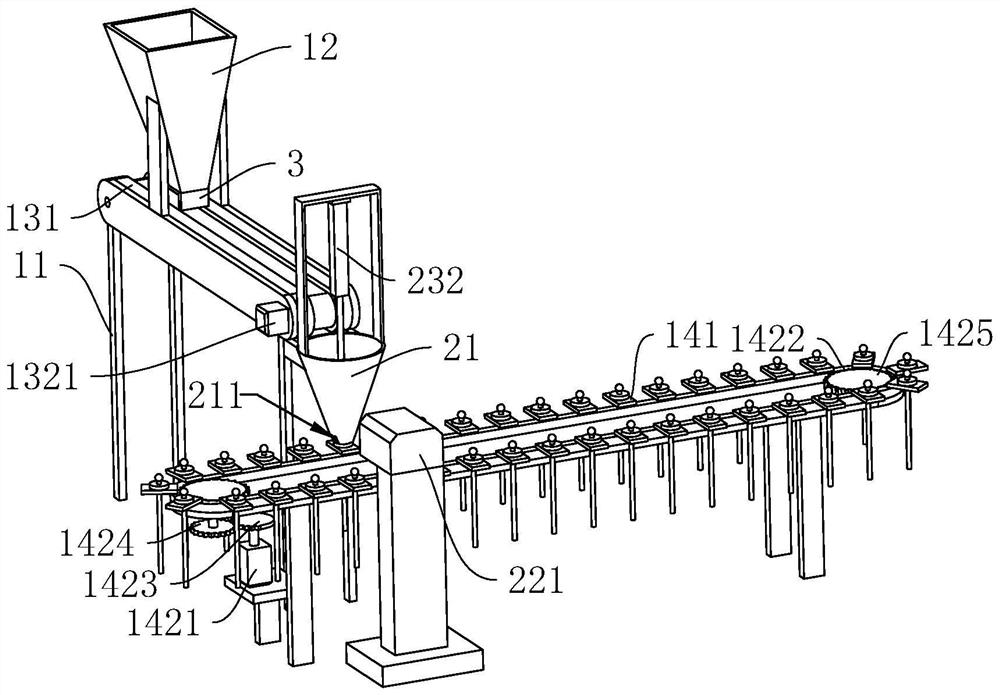

[0031] The following is combined with the attached Figure 1-3 The present invention will be further elaborated.

[0032] Embodiments of the present invention discloses an automatic installation of a dust ring device. Reference Figure 1 The automatic installation of the dust ring device includes the setting of the feeding member 1 and the installation member 2, the feeding member 1, which is convenient for the transport of the dust ring and the cable tie, and then facilitates the installation of the member 2 to assemble the dust ring and the cable tie, improve the assembly efficiency of the cable tie and the dust ring, and at the same time, reduce labor costs.

[0033] Reference Figure 1, the feeding member 1 includes a bracket 11, a storage hopper 12, a first feeding assembly 13 and a second feeding component 14, the storage hopper 12 is welded to the bracket 11, the storage hopper 12 is opened on the bottom wall of the discharge hole 121, the discharge hole 121 is used for the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com