Method for preparing plastic-free food paperboard

A technology for cardboard and food, applied in the direction of textiles, papermaking, papermaking, packaging paper, etc., can solve expensive problems and achieve the effect of preventing air from entering the reaction chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

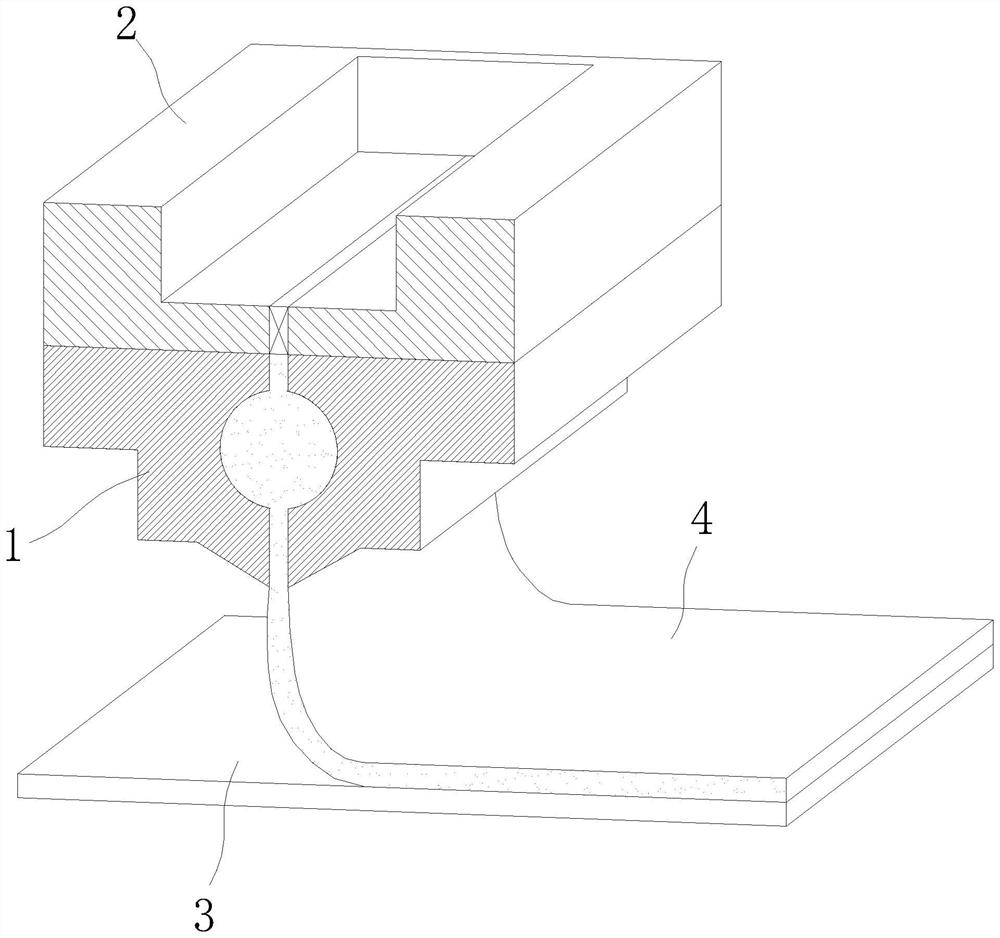

[0065] Specific embodiment one: please refer to Figure 1-9 A method for preparing plastic-free food jam, comprising the following steps:

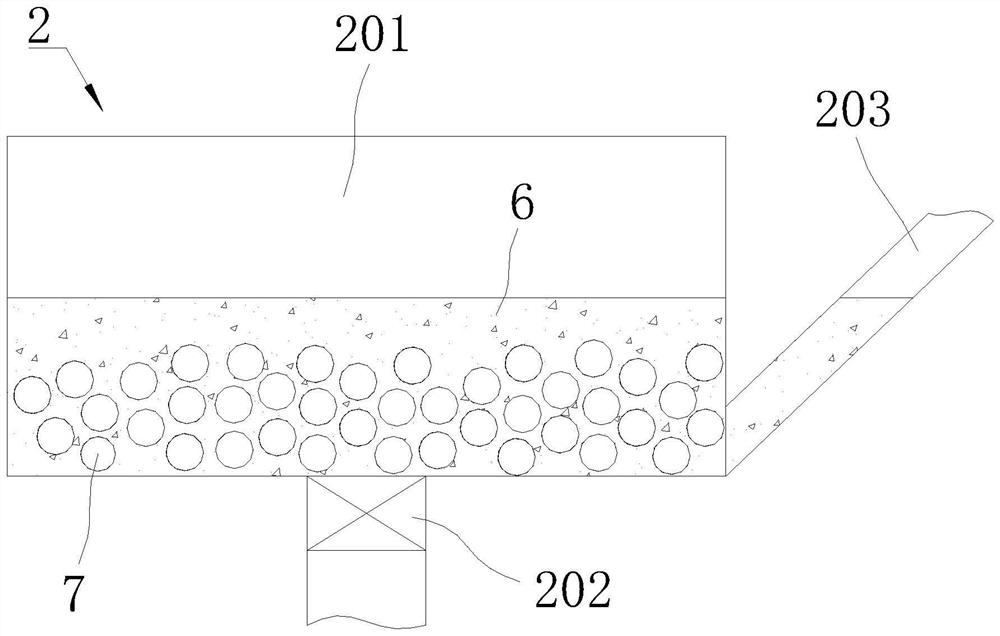

[0066] Using the above-mentioned equipment, according to the above-mentioned method, put 100-150 parts of pigments, 2-6 parts of dispersants, 1-5 parts of lubricants, 20-50 parts of adhesives, and 1-10 parts of auxiliary agents in parts by weight. In the reaction chamber 201, oil is passed into the reaction chamber 201 from the oil hole at the bottom of the reaction chamber 201 until the oil is immersed in all the raw materials, and the liquid level of the oil is higher than the raw materials by more than 2 cm. After standing for 2 hours, the entrained raw materials The air floats and discharges the air, so that the raw materials are stored in an environment insulated from the air.

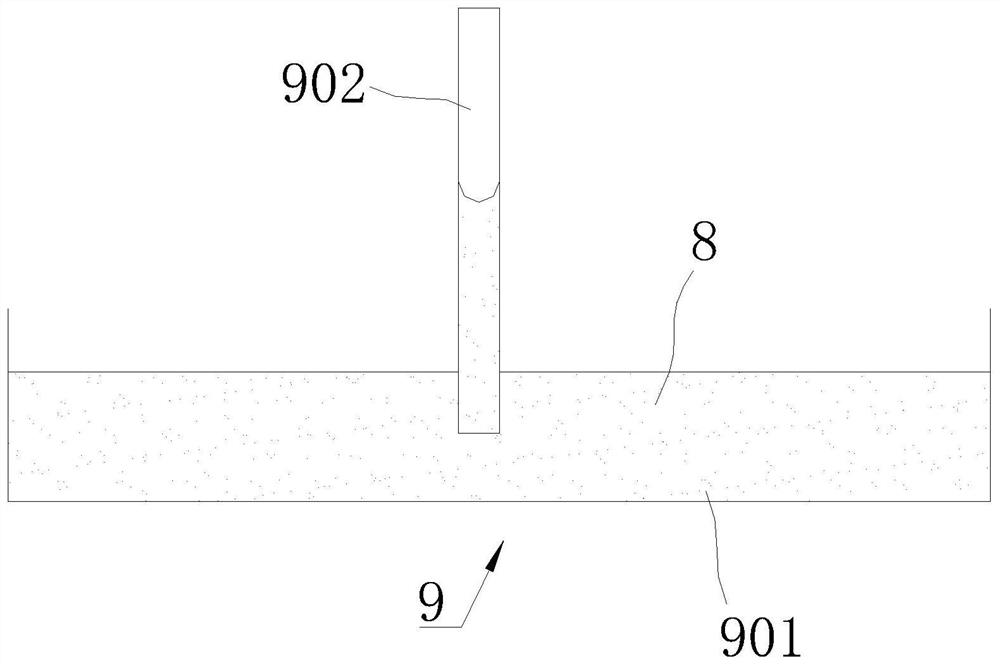

[0067] The box 901 is filled with water, and the lower end of the capillary 902 is inserted under the water surface. The water rises in the capillary 902 due...

specific Embodiment 2

[0076] Specific embodiment two: on the basis of specific embodiment one, please refer to Figure 10 A method for preparing plastic-free food jam, the drainage pipe 203 has a U-shaped trap 204; the bottom of the trap 204 is higher than the liquid level of the oil 6; the bottom of the trap 204 is lower at the height of the connecting port.

[0077] There is no water in the water trap 204 at first, when the capillary 902 continuously delivers water to the water trap, the upper limit of the water storage at the bend of the water trap 204 is reached, and the water is discharged into the reaction chamber 201. At the same time, the water trap 204 and The drainage tube 203 at the lower end also constitutes a siphon, which speeds up the delivery of water.

[0078] In addition, the water trap 204 is provided with a valve near the port of the reaction chamber 201. After the valve 202 in the reaction chamber 201 is opened, the valve is closed, and the valve is controlled by an external c...

specific Embodiment 3

[0079] Specific embodiment three: different from specific embodiment one, the coating 4 prepared in the reaction chamber 201 communicates with the temporary storage chamber of the applicator head 1 through the valve 202 located at the bottom side of the reaction chamber 201, and the valve 202 is a solenoid valve Combination with mechanical safety valve; forming electromagnetic safety valve, this electromagnetic safety valve is the prior art, has the common characteristics of electromagnetic valve and mechanical valve, that is, after the pressure received reaches or exceeds the set threshold, the valve opens, but The electromagnetic control valve is opened and no longer closed, and the valve changes from normally closed to normally open only after the pressure received reaches or exceeds the set threshold. When the upper opening of the electromagnetic safety valve receives the pressure of the complete coating 4 (the coating 4 in which the solid material 7 in the reaction chamber...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap