Surface area measuring method and system for rotating type container

A measurement method and surface area technology, applied in the field of surface area measurement, can solve the problems of low detection efficiency and high cost, and achieve the effects of increasing calculation speed, improving processing speed and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

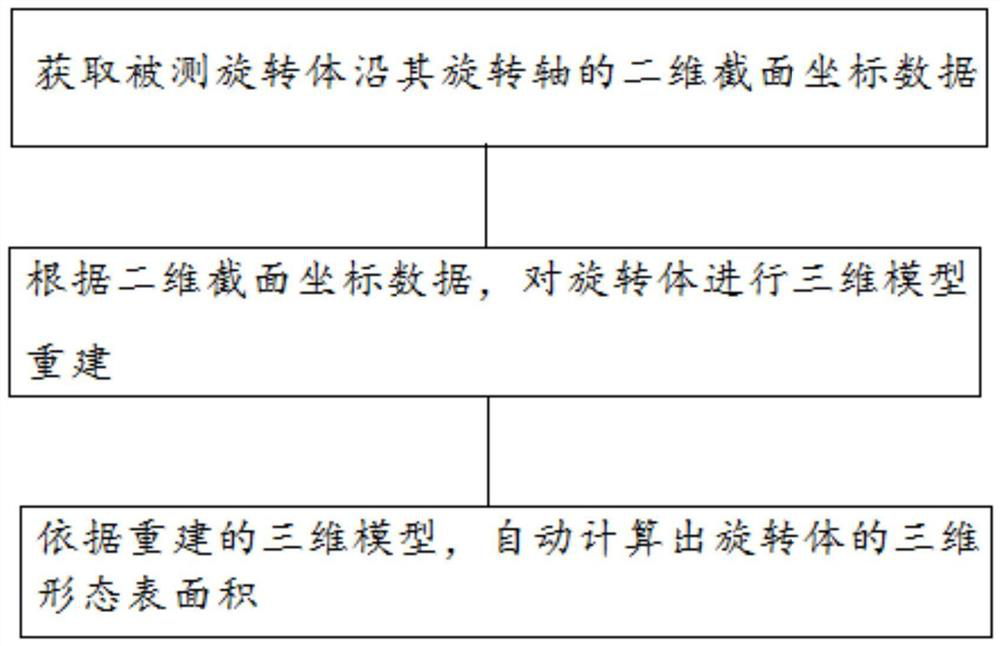

[0036] like figure 1 As shown, the present embodiment provides a method for measuring the surface area of a revolving container, including:

[0037] Obtain the two-dimensional cross-sectional coordinate data of the measured rotating body along its rotation axis;

[0038] According to the two-dimensional cross-section coordinate data, the three-dimensional model reconstruction of the rotating body is carried out;

[0039] According to the reconstructed 3D model, the 3D surface area of the rotating body is automatically calculated;

[0040] By obtaining the coordinate data of the two-dimensional section of the three-dimensional rotating body along its axis of rotation, the three-dimensional shape surface area is deduced by computer modeling. Compared with the existing three-dimensional surface area measuring device, while reducing the cost of the automatic measuring device, the measuring efficiency is improved.

[0041] In this embodiment, when obtaining the two-dimension...

Embodiment 2

[0055] This embodiment provides a surface area measurement system for a rotating container, including a data acquisition module, a three-dimensional reconstruction module and a surface area calculation module;

[0056] The data acquisition module is configured to: acquire two-dimensional cross-sectional coordinate data of the measured rotating body along its rotation axis;

[0057] The three-dimensional reconstruction module is configured to: perform three-dimensional model reconstruction on the rotating body according to the two-dimensional section coordinate data;

[0058] The surface area calculation module is configured to: automatically calculate the three-dimensional surface area of the rotating body according to the reconstructed three-dimensional model.

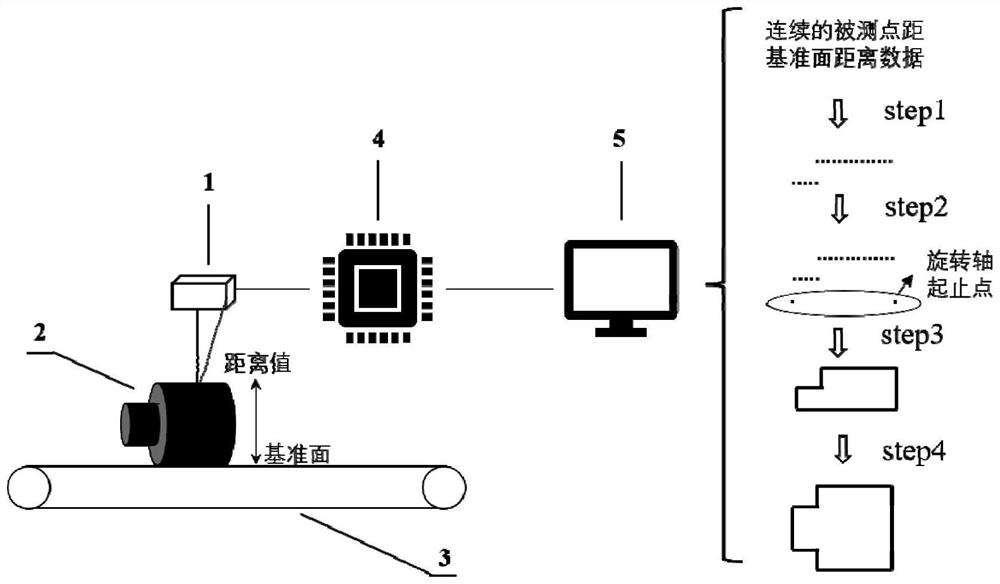

[0059] Specifically, such as figure 2 As shown, the data acquisition module can be set to a displacement sensor 1, and the three-dimensional reconstruction module and the surface area calculation module can be set...

Embodiment 3

[0068] This embodiment provides a computer-readable storage medium, on which a computer program is stored. When the program is executed by a processor, the steps of the method for measuring the surface area of a rotating container described in Embodiment 1 are realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com