Valve performance intelligent detection device and detection method

A technology of intelligent detection and performance, which is applied in the liquid/vacuum measurement of liquid tightness, and by measuring the acceleration and deceleration rate of the fluid, etc., can solve the problems of difficult to detect the valve body, high failure rate, affecting the detection efficiency, etc. The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

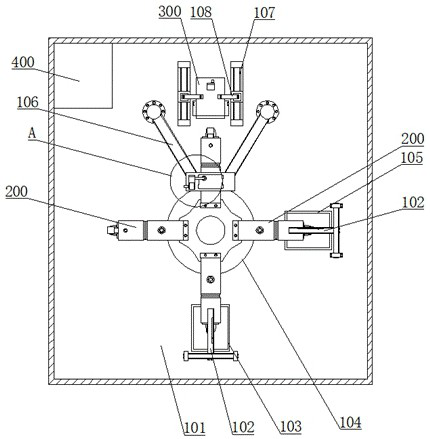

[0065] As shown in the figure, a valve performance intelligent detection device includes a body 101 and a control terminal 400. A rotating seat 104 is installed on the body 101. The rotating seat 104 is driven to rotate by a stepping motor, and the stepping motor is electrically connected to the control terminal 400. connected, the operating parameters of the stepper motor can be set through the control terminal 400 .

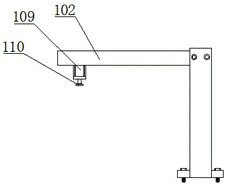

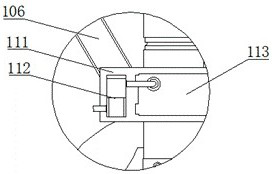

[0066] Several clamping arms 200 are evenly and fixedly installed along the ring on the rotating seat 104, and the valve body 206 can be clamped or unloaded through the clamping arms 200, and one end of the valve body 206 can be arranged on the body 101 through the clamping arms 200. The inflatable component is connected with the inflatable component, and the inflatable component is used to fill the detection gas into the valve body 206 . A drive mechanism one 107 is also installed on the body 101, and a detection assembly 300 is installed on the drive mechanis...

Embodiment 2

[0083] A detection method of a valve performance intelligent detection device, comprising the following steps:

[0084] S1. According to the size specification of the valve body 206 to be tested, adjust the position of the limit switch 224 and the unloading cylinder 220, and set the feed rate of the sliding seat 215 driven by the driving mechanism 217; install the corresponding type of connecting pipe 2 212;

[0085] S2. Insert the valve body 206 into the through hole. When the positioning block 207 is stuck into the groove on the surface of the valve body 206 under the elastic force of the spring 209, the electric gripper 205 is controlled to clamp the valve body 206 outside the through hole. ;

[0086] S3. Control the driving mechanism three to drive the connecting pipe 1 218 to rotate, and control the driving mechanism 2 217 to drive the sliding seat 215 to move toward the valve body 206; when one side of the sliding seat 215 contacts the limit switch 224, the driving mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com