Static performance testing device suitable for multi-size static pressure air bearing

A test device and static performance technology, which is applied in the direction of mechanical bearing test, measuring device, and the use of stable tension/pressure test material strength, etc., can solve the problem of inability to adjust the angle of the decoupling ball, the loading deviation of the tested part, and the inability to achieve static Pressure air bearing static performance test and other issues, to achieve superior output continuity and precise control degree, to ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

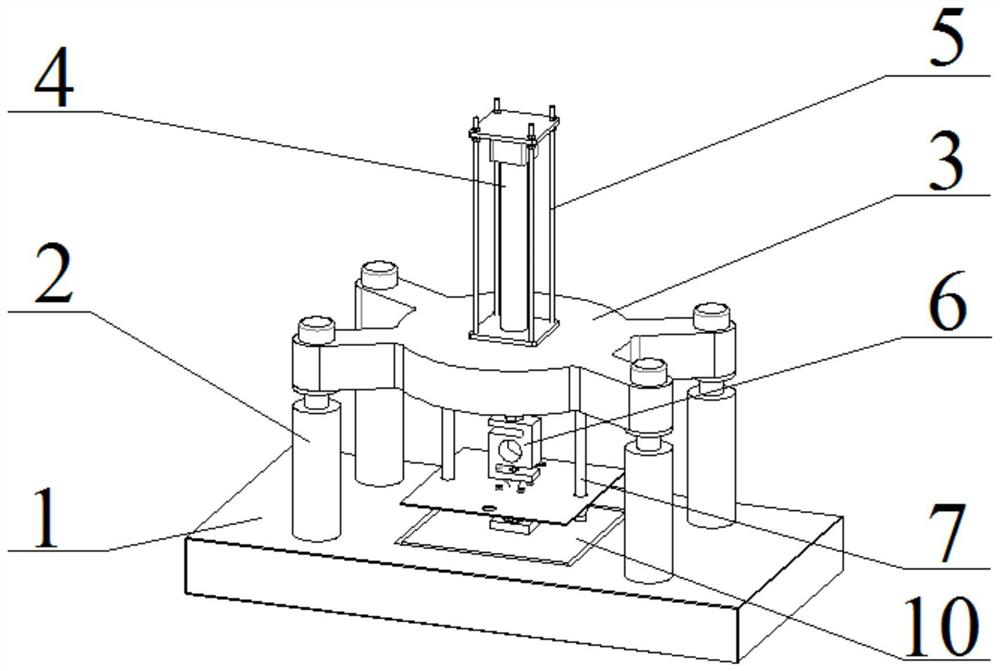

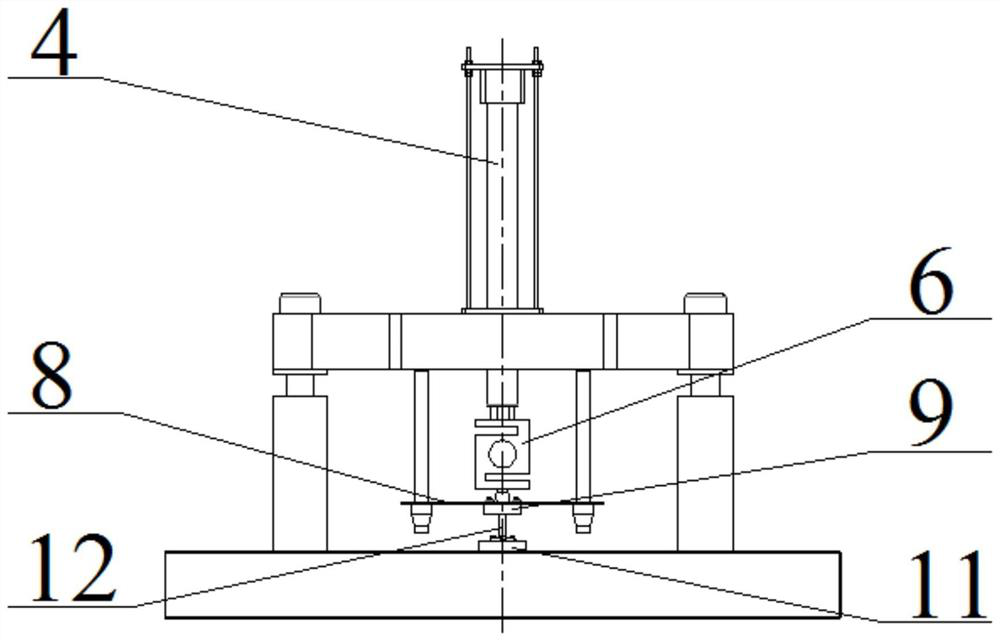

[0032] Specific implementation mode one: refer to Figure 1 to Figure 6 This embodiment is described. This embodiment provides a static performance test device suitable for multi-size static pressure air bearings. The test device includes a marble vibration isolation platform 1, four height-adjustable legs 2, a support platform 3, Loading module, working condition regulation module and air bearing module 10;

[0033]The center of the marble vibration isolation platform 1 is processed with a groove, the air-floating support module 10 is arranged in the groove at the center of the marble vibration isolation platform 1, and the four height-adjustable feet 2 are arranged vertically on the marble isolation platform 1. The upper surface of the vibration platform 1, and the fixed end of each height-adjustable leg 2 is fixedly connected with the upper surface of the marble vibration isolation platform 1, and the support platform 3 is set on the adjustment ends of the four height-adjus...

specific Embodiment approach 2

[0035] Specific implementation mode two: refer to figure 1 and Figure 6 This embodiment will be described. This embodiment is to further limit the air-floating support module 10 described in Embodiment 1. In this embodiment, the air-floating support module 10 is an air-floating supporting marble. Other compositions and connection methods are the same as those in Embodiment 1.

[0036] In this embodiment, the vibration damping property of the marble itself is used as the supporting plane during the measurement, which can effectively absorb the vibration amplitude generated by the loading module during the loading of the measured component during the measurement, and effectively protect the measured component.

specific Embodiment approach 3

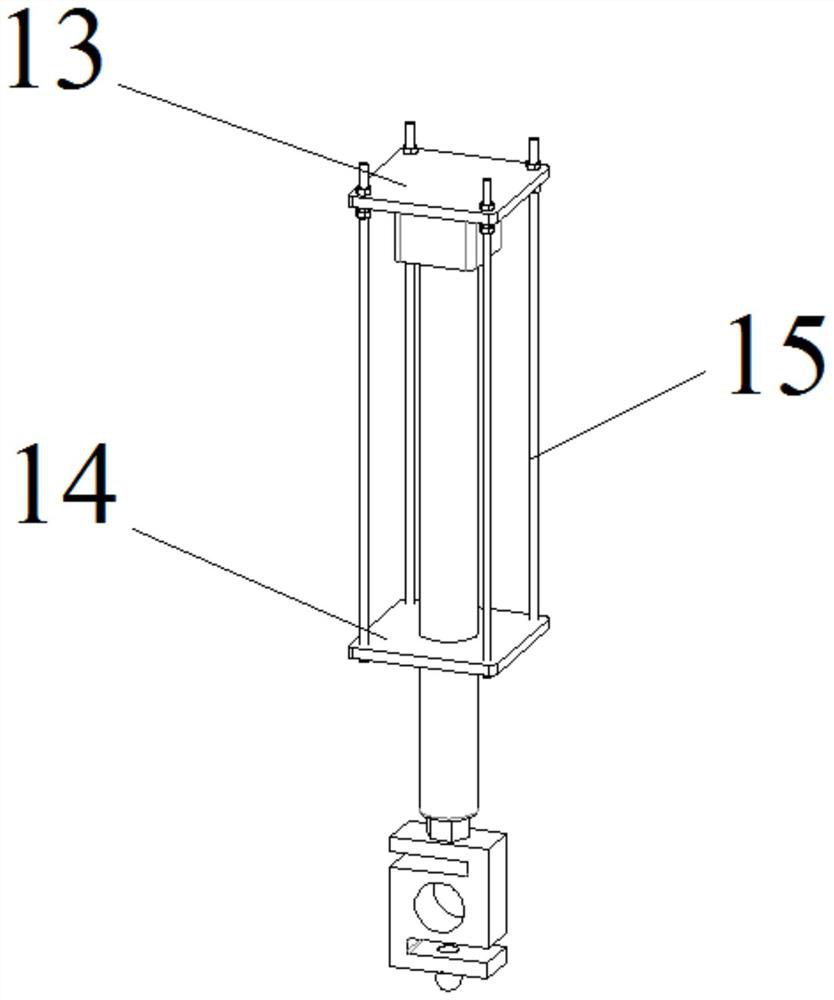

[0037] Specific implementation mode three: refer to Figure 1 to Figure 6 Describe this embodiment. This embodiment is to further limit the loading module described in Embodiment 1. In this embodiment, the loading module includes an electric cylinder 4, a support frame 5 and a force sensor 6. The support frame 5 It is arranged on the upper surface of the support platform 3, and the support frame 5 is disassembled and connected with the support platform 3, the electric cylinder 4 is placed upside down in the support frame 5, the housing in the electric cylinder 4 is fixedly connected with the inner top of the support frame 5, and the electric cylinder The end of the piston rod in 4 passes through the bottom of the support frame 5 and the installation hole on the support platform 3 in sequence and is fixedly connected with the force sensor 6 arranged below the support platform 3 . Other compositions and connection methods are the same as those in Embodiment 1.

[0038] In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com