Finite element analysis method and system for installation strength of rail transit air conditioner rack

A rail transit and analysis method technology, applied in the direction of instrumentation, geometric CAD, design optimization/simulation, etc., can solve problems such as modeling, influence, and conservative results of installation structure strength, and achieve the effect of improving efficiency and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions protected by the present invention will be specifically described below in conjunction with the accompanying drawings.

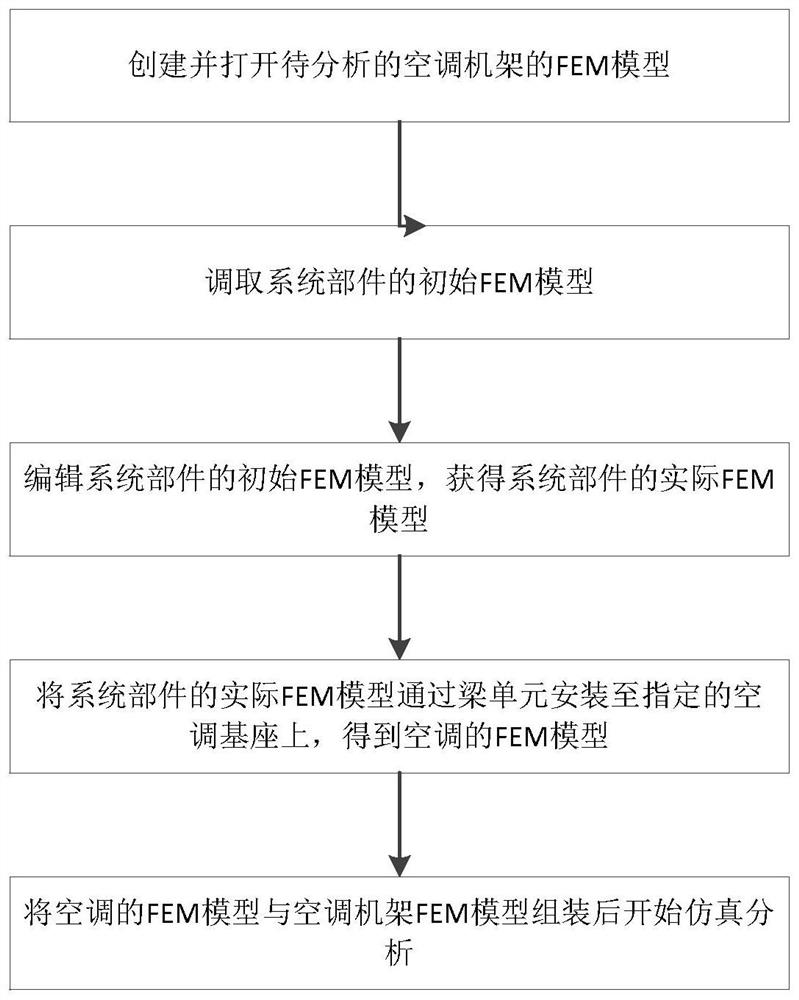

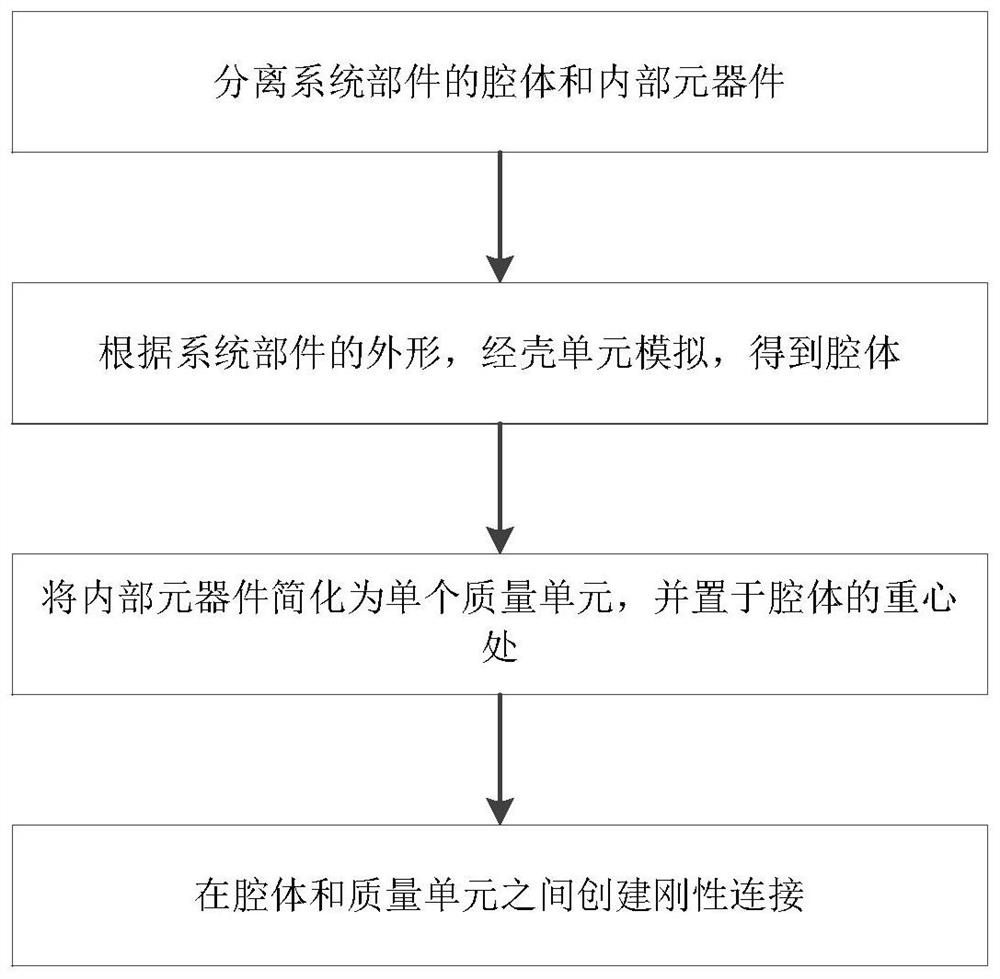

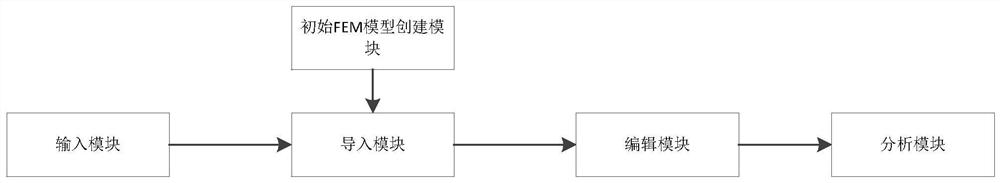

[0033] Please refer to Figure 1 to Figure 2 . The finite element analysis method of a kind of rail transit air-conditioning frame installation strength that the present invention proposes comprises the following steps: obtain the FEM model of the air-conditioning frame to be analyzed, and obtain the FEM model of each lumped mass part in the air-conditioning; Then according to the actual Specifications, including size and mass, edit the properties of the FEM model of the lumped mass parts to obtain the actual FEM model of each lumped mass part, and then install the actual FEM model of the lumped mass of each mass part to the specified air-conditioning base through the beam element Then the simulation analysis can start after combining the assembly with the frame.

[0034] Specifically, first create and open the FEM model of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com