Self-adaptive adjusting device for gap between compression roller and circular mould and control method of self-adaptive adjusting device

A self-adaptive adjustment and pressure roller technology, applied in applications, feed, food science, etc., can solve the problems of increasing time and labor costs, increasing equipment maintenance difficulty, reducing production efficiency, etc., to prevent abnormal wear, avoid mechanism operation, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

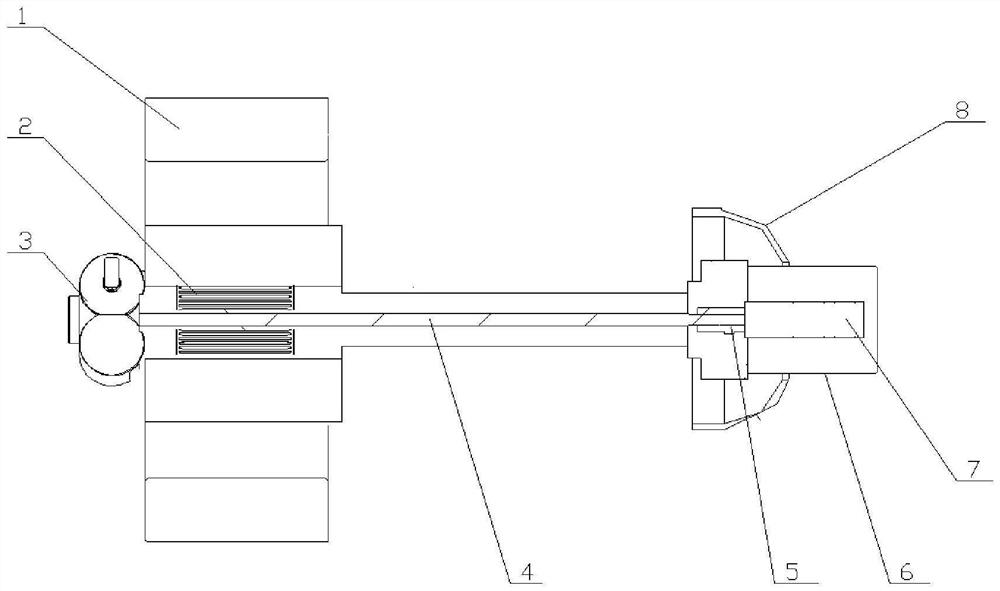

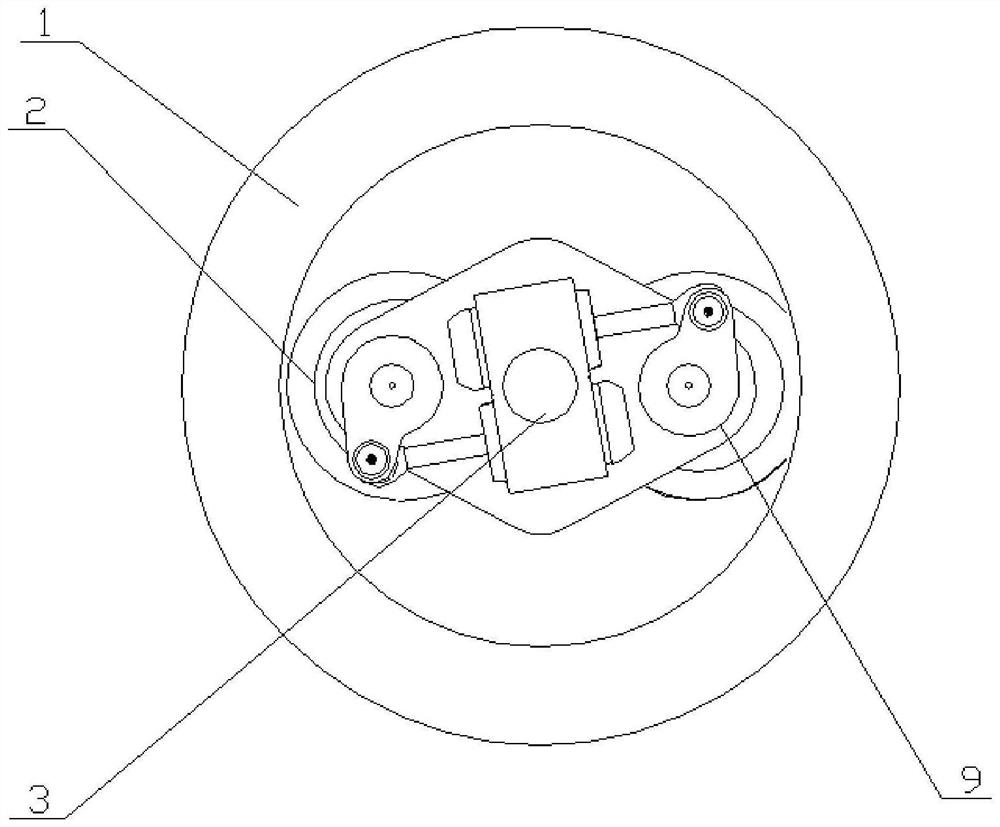

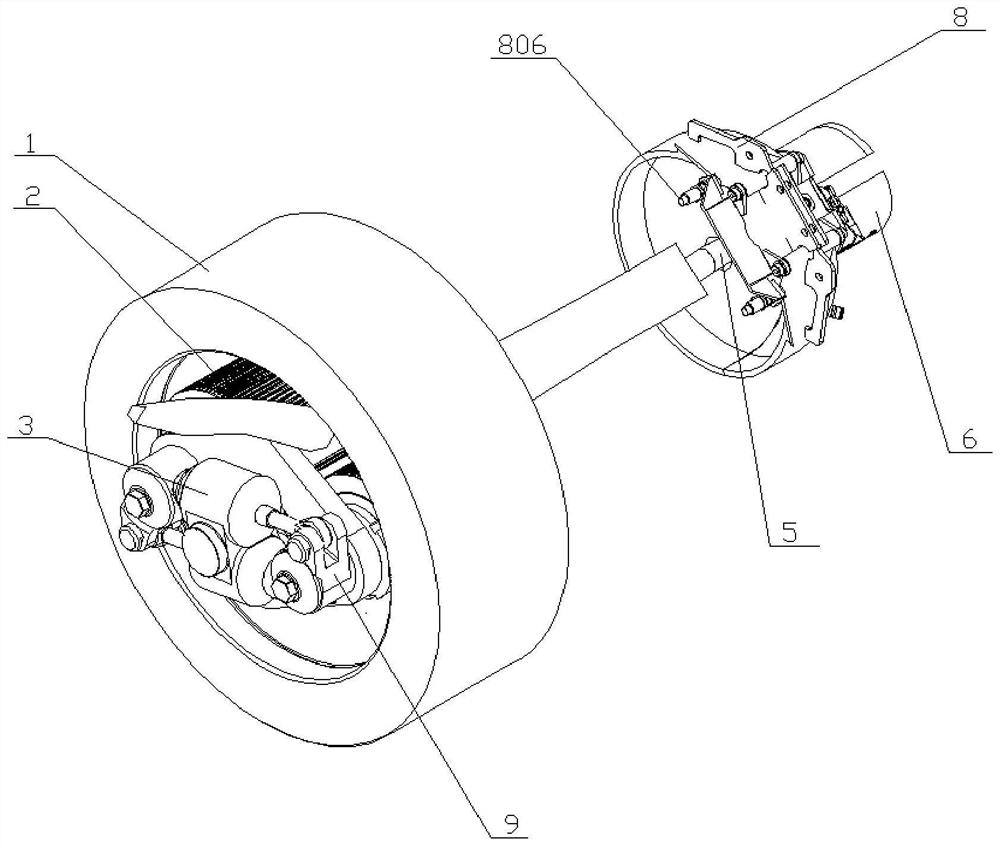

[0064] This embodiment aims at the inconvenient problem of manually adjusting the gap between the pressure rollers of the ring mold, and provides an adaptive adjustment device for the gap between the pressure roller and the ring mold. 4. Composed of counting mechanism 5, pneumatic transmission and distribution assembly 6, air motor 7, shield 8, pressure roller adjustment mechanism 9 and self-adaptive control system.

[0065] Device principle:

[0066] When the operator enters the adjustment command through the control system, the control system adjusts the air intake by controlling the opening and closing of the air circuit, and then drives the air motor to rotate. The displacement is converted into radial displacement to drive the pressure roller adjustment lever to move back and forth, and then drive the pressure roller adjustment arm to rotate, and then adjust the pressure roller to adjust the gap between the pressure roller and the ring die by adjusting the rotation of the...

Embodiment 2

[0080] In order to realize the self-adaptive adjustment of the pressure roller gap of the ring die, this embodiment provides a control method for the self-adaptive adjustment device of the pressure roller ring die gap, as follows:

[0081] First, the zero position is automatically adjusted according to the use of the pressure roller and the ring die. After the zero position is determined, the gap between the pressure roller and the ring die can be adjusted to increase or decrease. Assuming that the initial value of the pressure roller ring die gap is A0, the required pressure roller can be set according to the demand. If the gap value of the ring die is A, the control system will judge by itself.

[0082] When A>A0, the control system will control the air path to control the rotation of the air motor 7 through the air path transmission distribution component 6, and the air motor 7 drives the gear transmission mechanism 3 on the front plate to rotate through the transmission sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com