New energy automobile chassis detecting and conveying platform

A new energy vehicle and conveying platform technology, which is applied in the field of new energy vehicle chassis detection and conveying platform, can solve the problems of chaotic distribution of chassis, lower detection efficiency, low intelligence and mechanization degree, etc., so as to avoid labor cost and mechanization degree high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

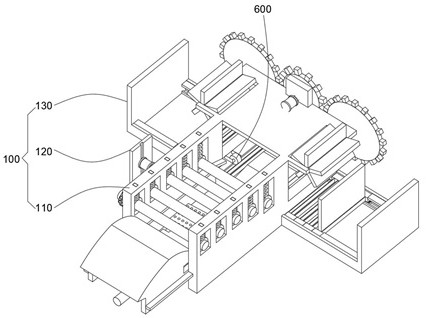

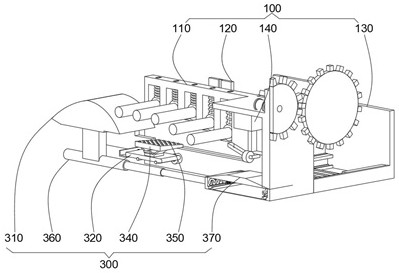

[0045] combine Figure 1-8As shown, a new energy vehicle chassis detection and delivery platform provided by the present invention includes a frame module 100, a transmission module 200, a classification module 300, a sorting module 400, and a lifting module 500. The frame module 100 includes a frame 110, and the machine The frame 110 plays a role in supporting the overall structure in the present invention, making the installation and layout of the overall structure more precise, and the L-shaped plate 120 connected to the frame 110, the L-shaped plate 120 limits and lifts the first motor 240 The guide in the center, the vertical center plane symmetry about the frame 110 and the finishing frame 130 connected with the frame 110 and the detection device 140 installed inside the frame 110, the finishing frame 130 is used to classify and store qualified and unqualified automobile chassis , the detection device 140 is used to detect the performance of the automobile chassis, and a...

Embodiment 2

[0056] combine figure 1 , 3 , 4, and 6, on the basis of Embodiment 1, a plurality of rubber wheels 600 are installed inside the frame 110, and the plurality of rubber wheels 600 are connected with the frame 110 through U-shaped damping rods, close to the frame The height of the rubber wheels 600 on the front side of the frame 110 is less than the height of the rubber wheels 600 away from the front side of the frame 110. Rubber wheels 600 of different heights can help to detect qualified chassis to slide autonomously to the finishing frame 130 on the front side of the frame 110.

Embodiment 3

[0058] combine figure 1 with image 3 As shown, in the above embodiment, inclined plates are installed on both side walls of the frame 110, the inclined plates are located between the inclined plate 340 and the trapezoidal plate 370, and the inclined plates are guaranteed to slide off from the plurality of rubber rollers 210 The chassis can slide smoothly onto multiple rubber wheels 600 .

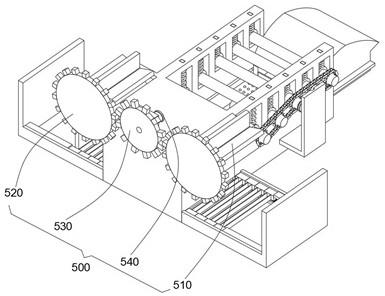

[0059] The working principle and application process of the present invention: when the present invention is put into practical use, (refer to the appended figure 1 , it is stipulated that the position of the first motor 240 is the rear side of the frame 110, the corresponding frontmost position of the first motor 240 is the front side of the frame 110, and then the position of the second motor 540 is the right side of the frame 110), the first The motor 240 drives the rubber roller 210 connected to it to rotate, and then with the cooperation of the multiple sprockets 220 and the chain 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com