Machine tool spindle

A technology for machine tool spindles and headstocks, applied to metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve problems such as short service life, achieve good integrity, prolong service life, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

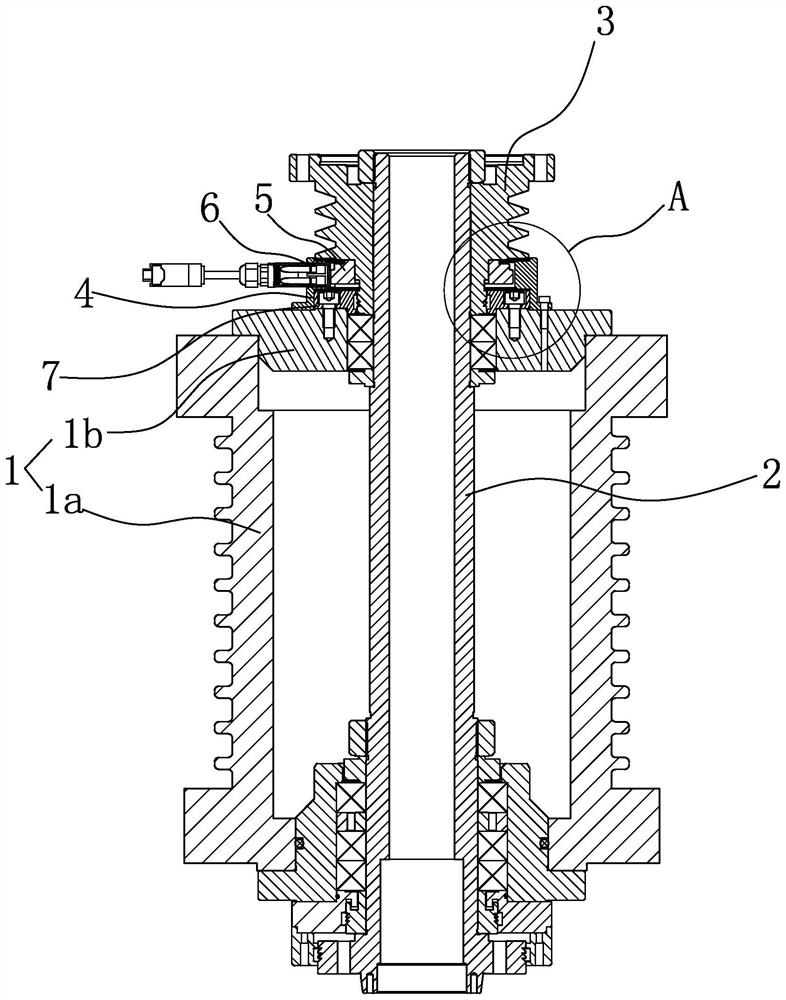

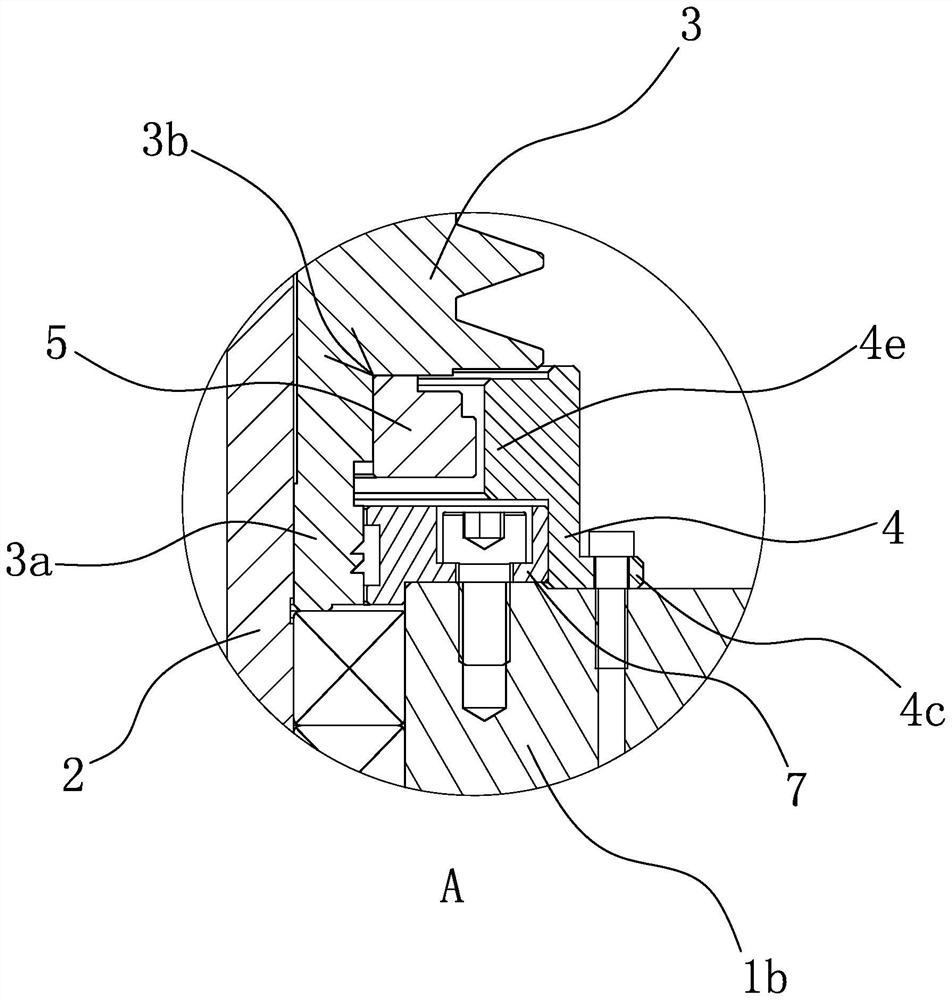

[0037] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7A with Figure 7BAs shown, a machine tool spindle includes a spindle box 1, an encoder, a shaft body 2 with one end protruding from the spindle box 1, and a rotating member that is arranged on the shaft body 2 that extends out of the spindle box 1 and that is linked with the shaft body 2. 3. An installation seat 4 is fixed on the end surface of the spindle box 1 for the shaft body 2 to protrude from, and the encoder includes a reading member 6 and a magnet set on the shaft body 2 protruding from the spindle box 1 and inside the installation seat 4. Ring 5. Mounting seat 4 is ring-shaped and one end is close to rotating part 3 (here abutting against is not leaning against, that is, mounting seat is very close to rotating part but does not form contact), and the side of mounting seat 4 is provided with The matching groove 4a that runs through the radial direction, the matching gr...

Embodiment 2

[0042] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in this embodiment, the outer side of the reading member 6 near the front position has a ring-shaped installation part, and the installation part is attached to the matching groove 4a on the mounting base 4 around the notch.

Embodiment 3

[0044] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in this embodiment, the rotating part 3 is not provided with an extension part 3a, and the magnetic ring 5 is directly sleeved outside the shaft body 2 and connected to the rotating part 3 is fixed by fasteners.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com