Slitter edge suction device

The technology of a suction duct and a rack is applied in the field of adsorption equipment, which can solve the problems of high cost, affect the workshop environment, and large adsorption noise, achieve the effect of low production and maintenance costs, and improve the adsorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

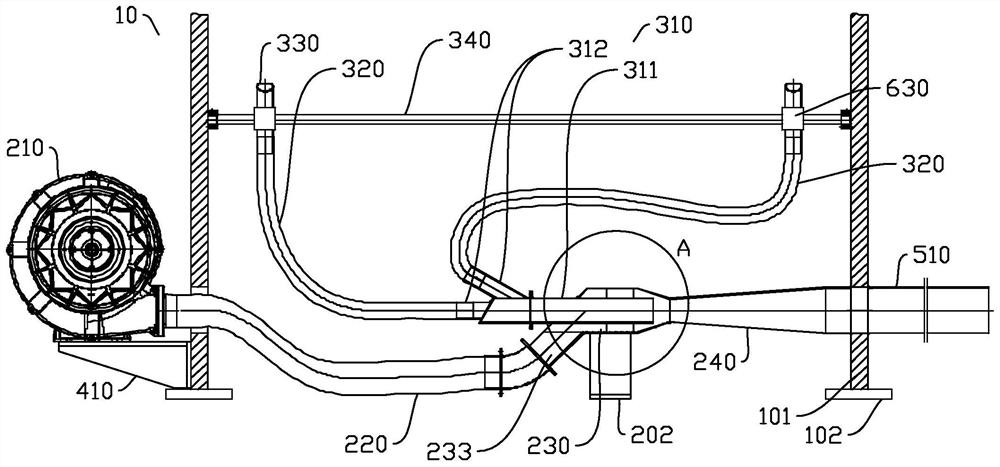

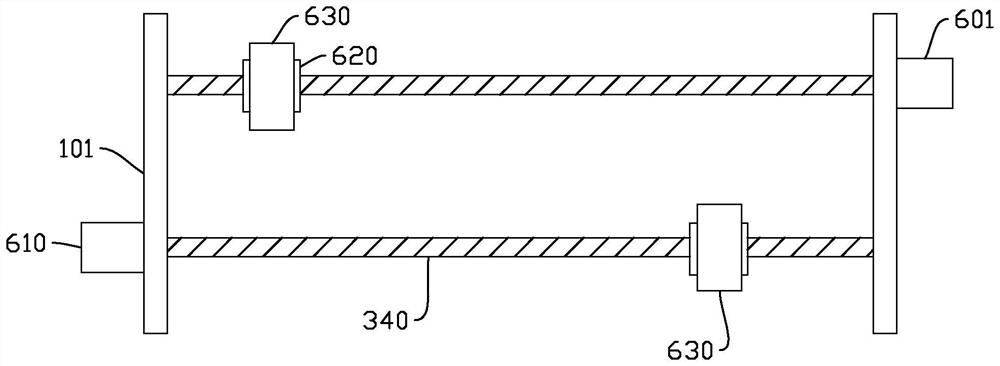

[0028] Such as Figure 1-2 As shown, the waste edge suction device provided by the present invention mainly includes a frame 10 and a pressure difference mechanism and a material suction mechanism arranged on the frame 10. The frame 10 is composed of two oppositely arranged wall panels 101, and The bottom of the plate 101 is provided with a support plate 102, the support plate 102 is arranged horizontally on the ground, and the wall plate 101 can be arranged vertically, and the gas pressure difference is formed by the pressure difference mechanism to guide the suction mechanism to absorb the waste.

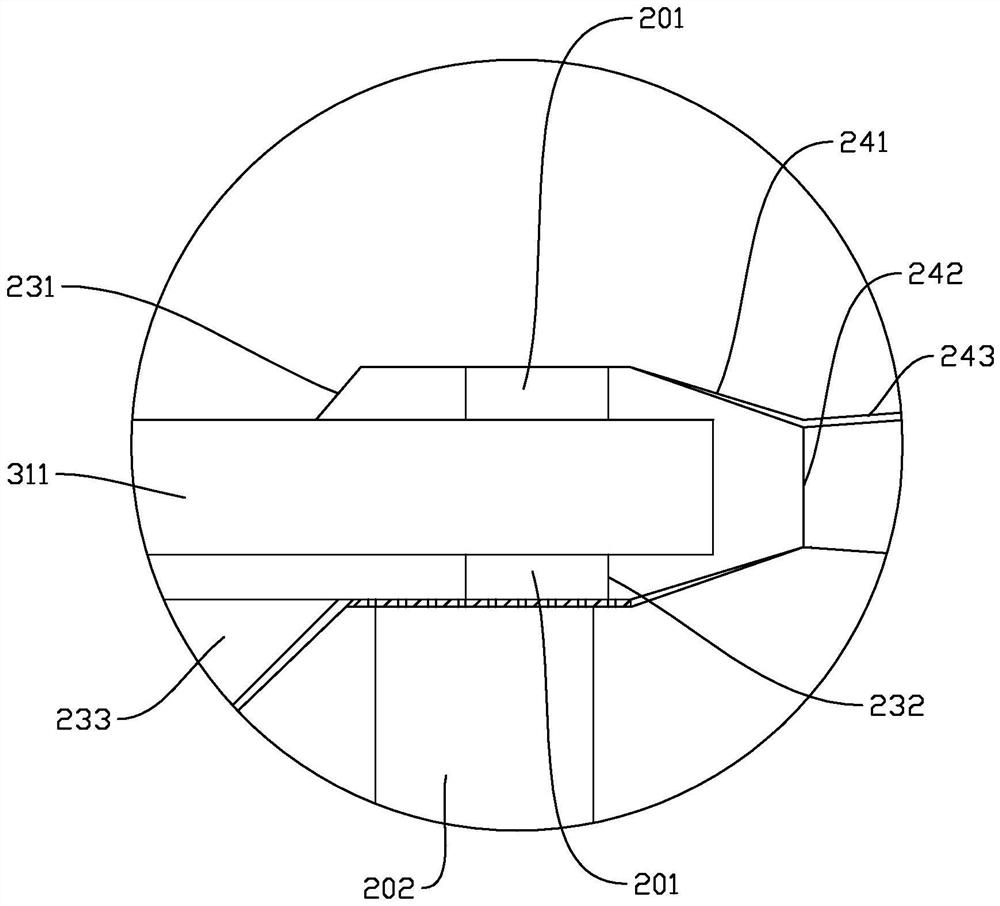

[0029] Wherein, the differential pressure mechanism includes a fan 210, an air guide pipe 220, a connecting pipe 230 and a Venturi tube 240. The air outlet 232 has an interface 233 on the wall of the connecting pipe 230 , the air guiding pipe 220 is connected to the interface 233 , and the venturi tube 240 is connected to the air outlet 232 .

[0030] The Venturi tube 240 is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com