High-precision wafer cutting positioning device and wafer cutting machine

A positioning device, high-precision technology, applied in the direction of fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problem of scrap wafers, can not guarantee the stability of the wafer and the accuracy of the position, the positioning and fixing structure is simple And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

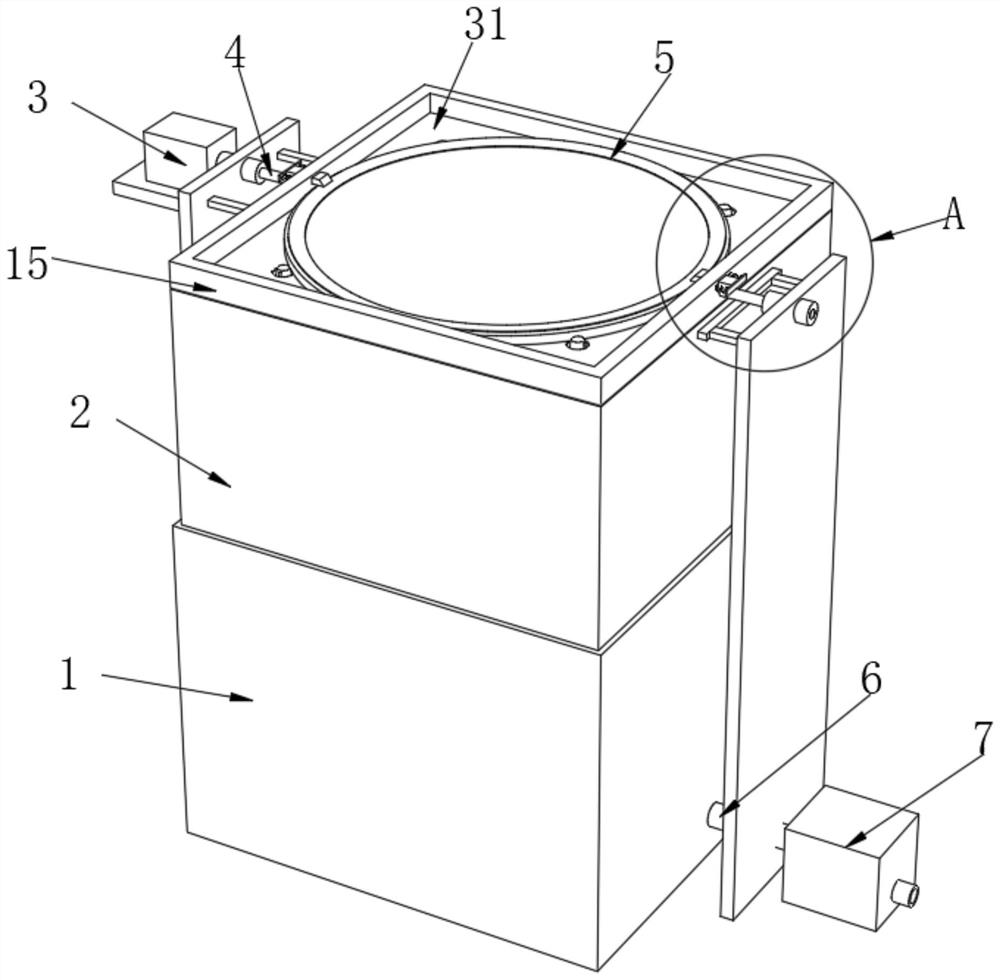

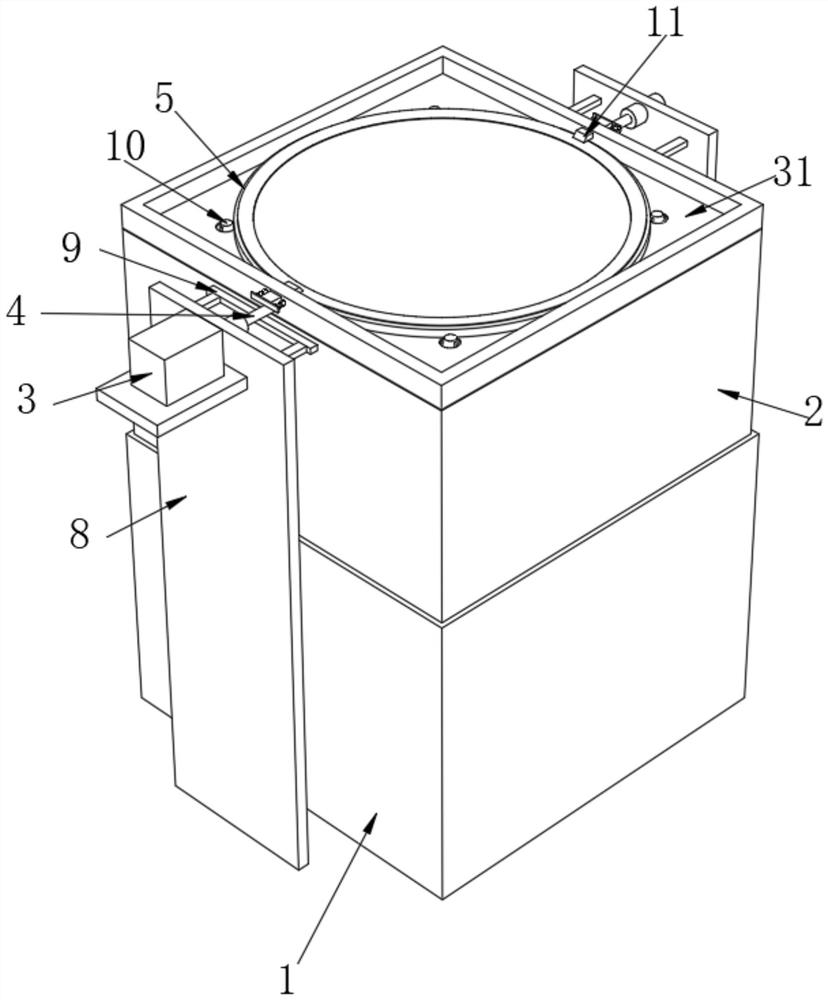

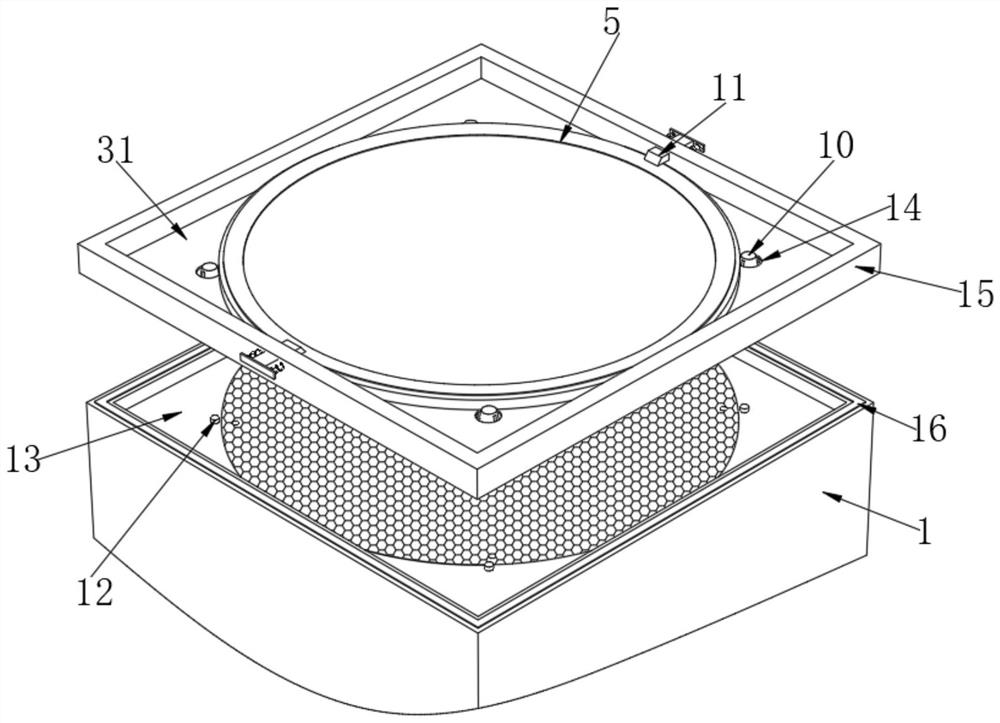

[0034] Such as Figure 1-4 As shown, a high-precision wafer cutting and positioning device and a wafer cutting machine include a base 1 and a sliding frame 2 slidably arranged on the top of the base 1, and a chute 21 is opened on the top of the base 1 along its height direction , the sliding frame 2 is slidingly connected with the base 1 through the sliding groove 21, and a first spring 33 is arranged inside the sliding groove 21, and the first spring 33 is placed between the base 1 and the sliding frame 2, which is beneficial to increase the sliding frame 2 Stability of sliding between base 1.

[0035] And the top of sliding frame 2 is provided with rotating frame 15, and the bottom of rotating frame 15 is in contact with the sealing strip 16 that sliding frame 2 top arranges, and the center position of both sides of rotating frame 15 is all fixedly connected with rotating shaft 4, can promote by rotating. The rotating frame 15 rotates around the centerline of the rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com