Ultrasonic welding probe using magnetostrictive material as driving source

A magnetostrictive material and ultrasonic welding technology, applied in the direction of using vibrating fluids, sewing tools, etc., can solve the problems of piezoelectric ceramics out of stock, increase in the amount of piezoelectric ceramics used in ultrasonic probes, and skyrocketing prices, reaching the speed of sound Small size, reduced use volume and quality, and large power capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

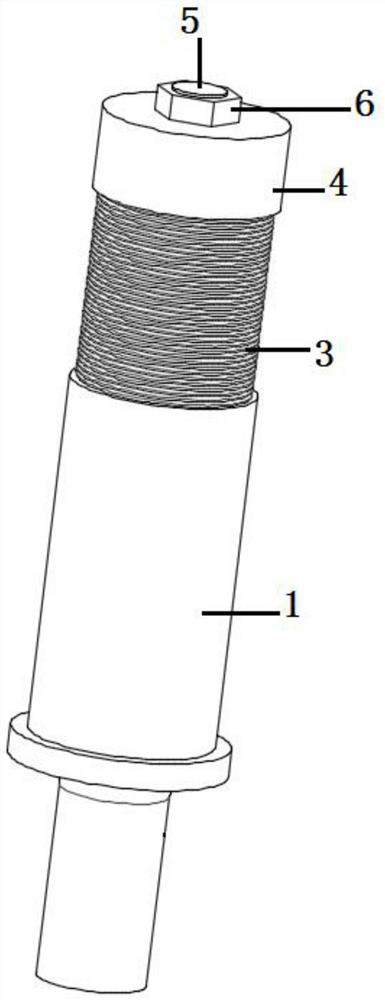

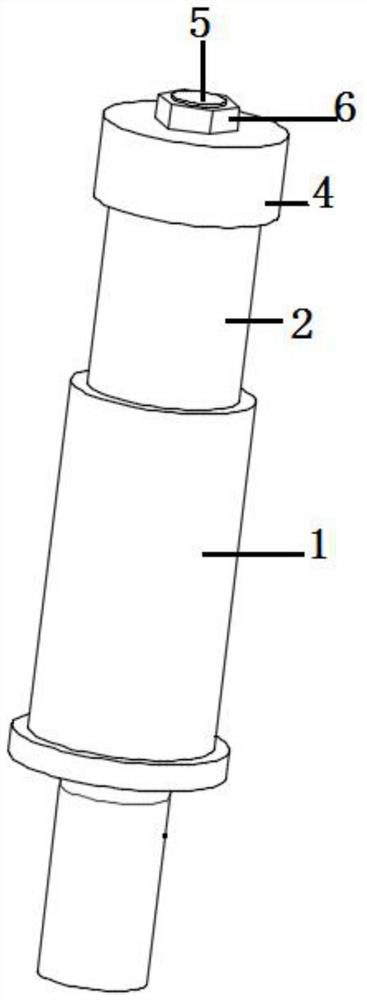

[0018] see figure 1 and figure 2 As shown, the specific disclosure of the embodiments of the present invention provides a technical solution of an ultrasonic welding probe using a magnetostrictive material as a driving source, which mainly includes: a horn 1, a magnetostrictive cylinder 2, a coil 3 and a rear cover Plate 4; the upper end of the horn 1 is abutted with a magnetostrictive cylinder 2, and the outside of the magnetostrictive cylinder 2 is sleeved and wound with a coil 3, and the upper end of the magnetostrictive cylinder 2 also includes a compressed rear cover plate 4.

[0019] In this embodiment, the magnetostrictive cylinder 3 is a cylinder made of magnetostrictive material. It also includes a prestressed screw 5 and a lock nut 6. The inside of the upper end of the horn 1 also includes a screw hole, through which a prestressed screw 5 is threaded, and the upper end of the prestressed screw 5 passes through the magnetostrictive column in turn. The shaft cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com