One-time mechanical turn-up boosting capsule drum

A capsule and mechanical technology, applied in the field of mold structure, can solve the problems of uneven turn-up force, high energy consumption, and many bubbles, and achieve the effects of uniform sidewall turn-up height, accurate material distribution and uniform turn-up force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

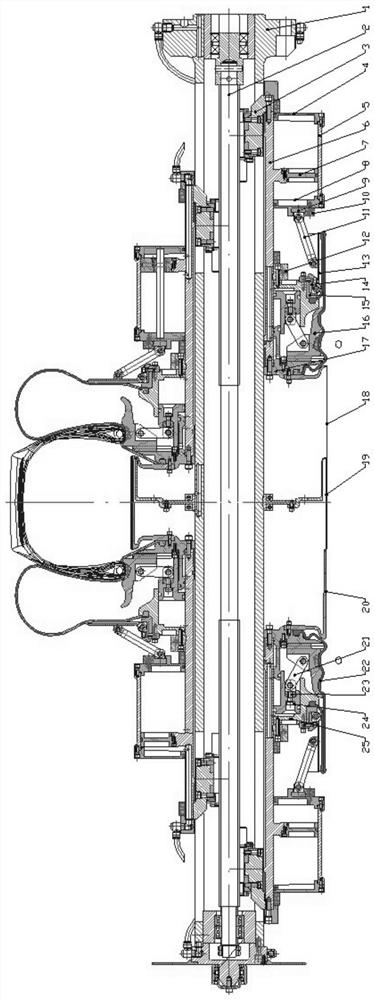

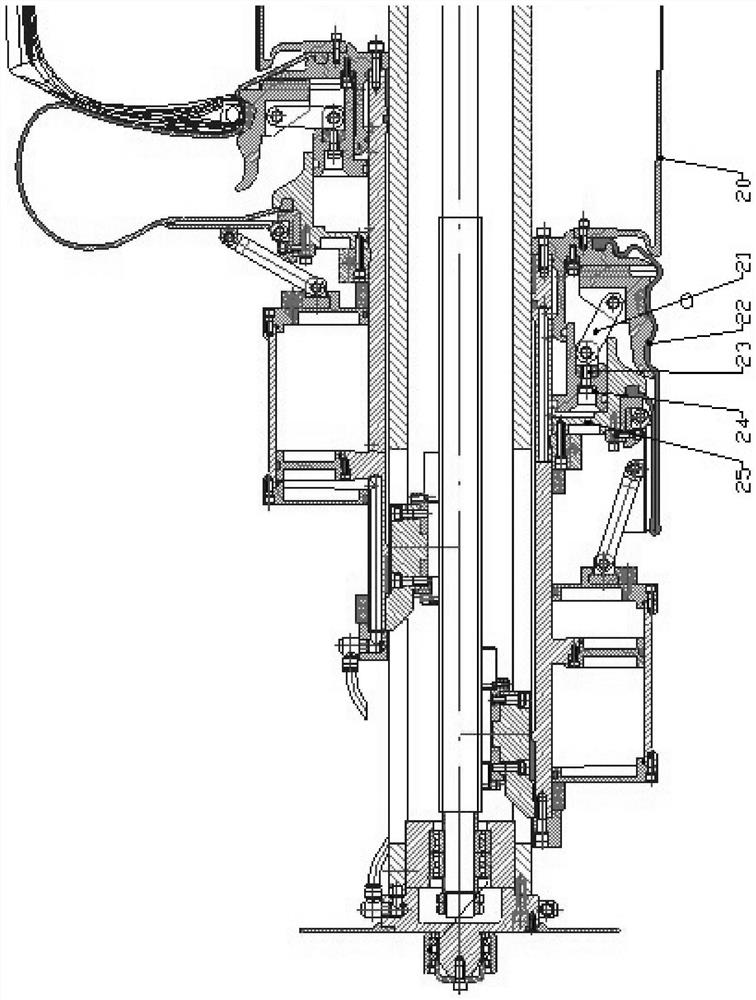

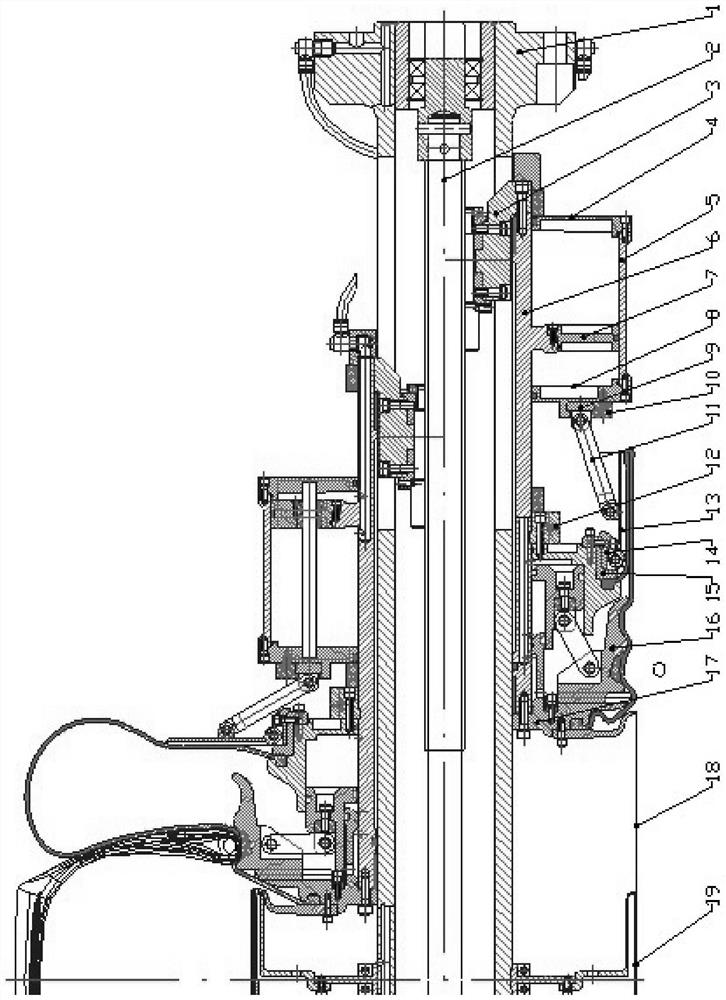

[0021] As shown in the figure: the supply includes main shaft 1, ball screw 2, transmission key 3, right cylinder head 4, cylinder body 5, side bushing 6, piston 7, left cylinder head 8, connecting rod seat C9, four petals Ring 10, large connecting rod 11, fixed ring 12, booster plate 13, connecting rod seat B14, capsule pressure ring 15, sector block 16, sector plate 17, outer ring 18, center ring 19, inner ring 20, small connecting rod 21, reverse package capsule 22, connecting rod seat A23, movable ring 24, cylinder body A25.

[0022] Preferably, the left cylinder head 8, the right cylinder head 4, and the cylinder block 5 constitute a double-acting cylinder, which is slidingly connected to the side bushing 6; the piston 7 is fixed on the side bushing 6; the One end of the large connecting rod 11 is connected to the connecting rod seat C9, and is fixed on the left cylinder head 8 through the four-petal ring 10, and the other end of the large connecting rod 11 is connected w...

Embodiment 2

[0024] As shown in the figure: the supply includes main shaft 1, ball screw 2, transmission key 3, right cylinder head 4, cylinder body 5, side bushing 6, piston 7, left cylinder head 8, connecting rod seat C9, four petals Ring 10, large connecting rod 11, fixed ring 12, booster plate 13, connecting rod seat B14, capsule pressure ring 15, sector block 16, sector plate 17, outer ring 18, center ring 19, inner ring 20, small connecting rod 21, reverse package capsule 22, connecting rod seat A23, movable ring 24, cylinder body A25.

[0025] Preferably, the left cylinder head 8, the right cylinder head 4, and the cylinder block 5 constitute a double-acting cylinder, which is slidingly connected to the side bushing 6; the piston 7 is fixed on the side bushing 6; the One end of the large connecting rod 11 is connected to the connecting rod seat C9, and is fixed on the left cylinder head 8 through the four-petal ring 10, and the other end of the large connecting rod 11 is connected w...

Embodiment 3

[0027] As shown in the figure: the supply includes main shaft 1, ball screw 2, transmission key 3, right cylinder head 4, cylinder body 5, side bushing 6, piston 7, left cylinder head 8, connecting rod seat C9, four petals Ring 10, large connecting rod 11, fixed ring 12, booster plate 13, connecting rod seat B14, capsule pressure ring 15, sector block 16, sector plate 17, outer ring 18, center ring 19, inner ring 20, small connecting rod 21, reverse package capsule 22, connecting rod seat A23, movable ring 24, cylinder body A25.

[0028] Preferably, the left cylinder head 8, the right cylinder head 4, and the cylinder block 5 constitute a double-acting cylinder, which is slidingly connected to the side bushing 6; the piston 7 is fixed on the side bushing 6; the One end of the large connecting rod 11 is connected to the connecting rod seat C9, and is fixed on the left cylinder head 8 through the four-petal ring 10, and the other end of the large connecting rod 11 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com