A microfluidic 3D printing composite material preparation device and method

A 3D printing and composite material technology, which is applied to the composite material preparation device and its preparation field, can solve the problems of high production cost, complex process, difficult to enhance the precise control of the uneven distribution of the phase, etc. The effect of controlled distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

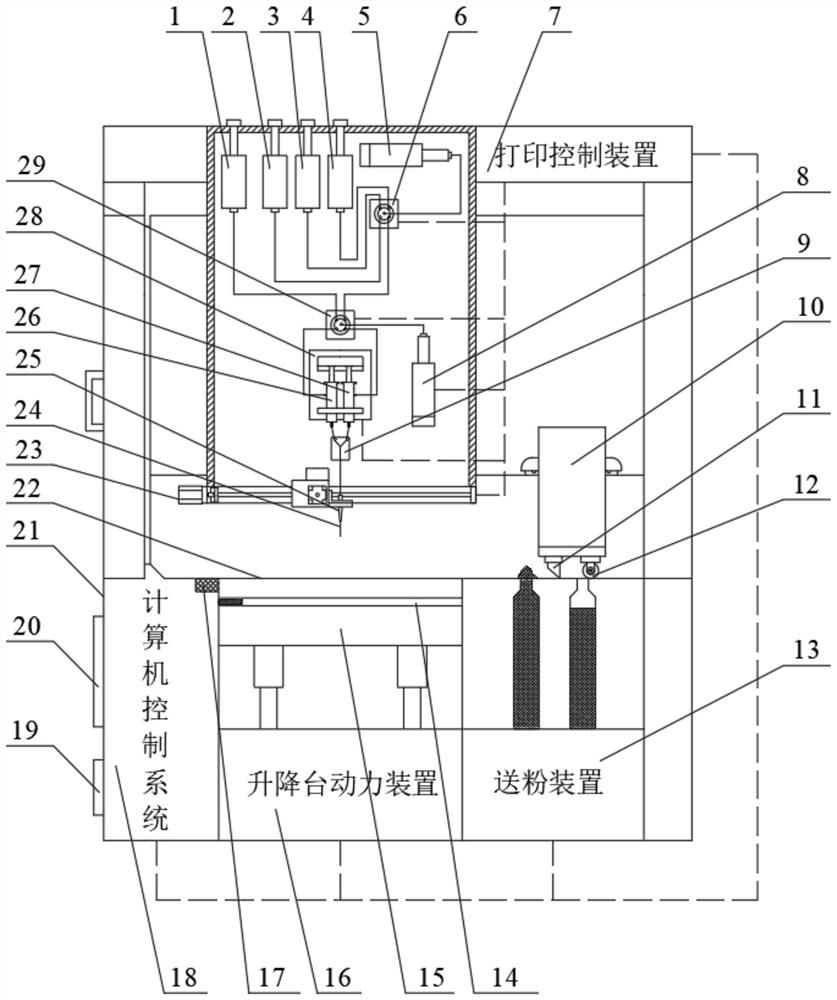

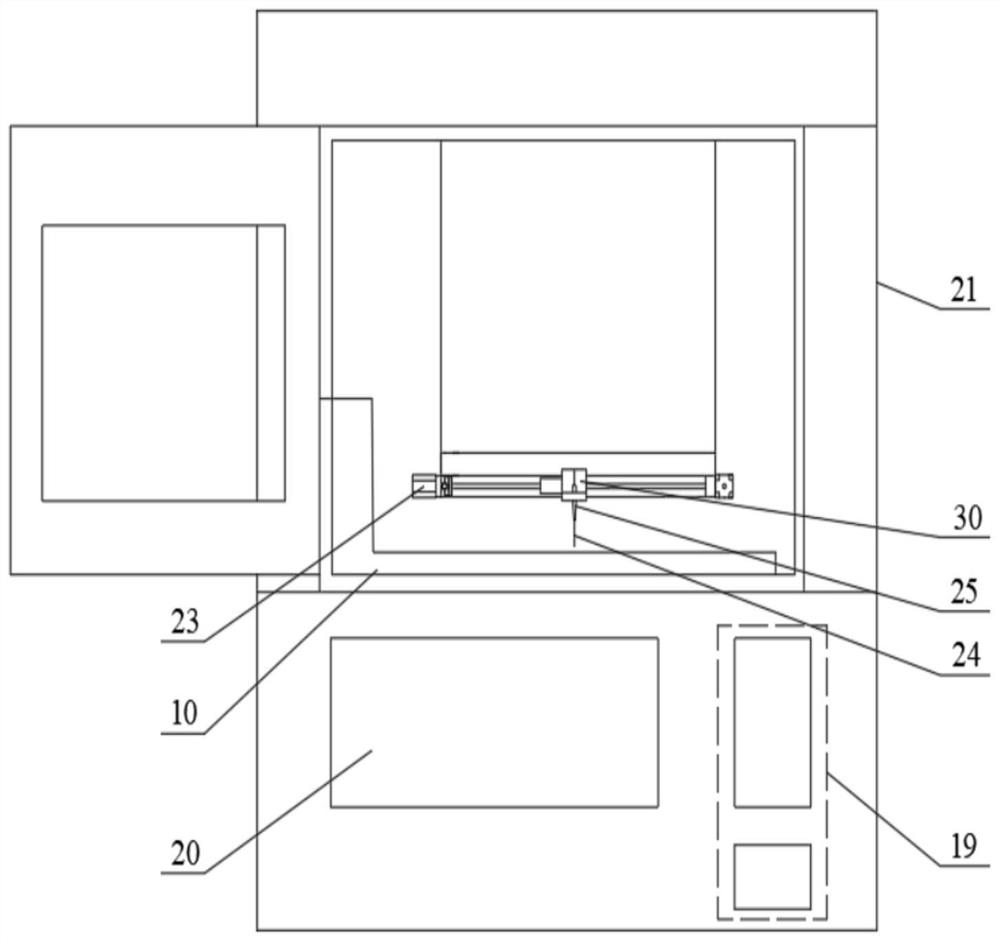

[0025] see figure 1 and figure 2 , a microfluidic 3D printing composite material preparation device of the present invention has an equipment box 21 outside, and the equipment box 21 is provided with a computer control system 18, a printing control device 7, a lifting table power device 16, and a powder feeding device. 13 and the mobile powder spreading device 10, the computer control system 18 is respectively connected to the printing control device 7, the lifting platform power device 16, the powder feeding device 13 and the mobile powder spreading device 10 through control lines. The computer control system 18 is provided with an input panel 19 and a display panel 20 outside.

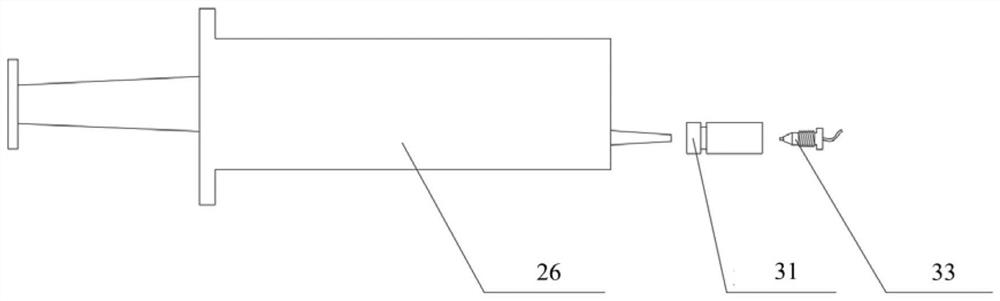

[0026] The top of the equipment box 21 is provided with a waste liquid tank 1 , a first liquid storage tank 2 , a second liquid storage tank 3 , a third liquid storage tank 4 , a first multi-channel switching valve 6 and a first metering injection pump 5 . The waste liquid tank 1 , the first liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com