A steel structure workshop and its construction method

A technology for steel structures and workshops, applied in heating methods, industrial buildings, building components, etc., can solve problems such as poor temperature regulation ability, and achieve the effects of ensuring safe use, avoiding a large amount of settlement, and clear air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

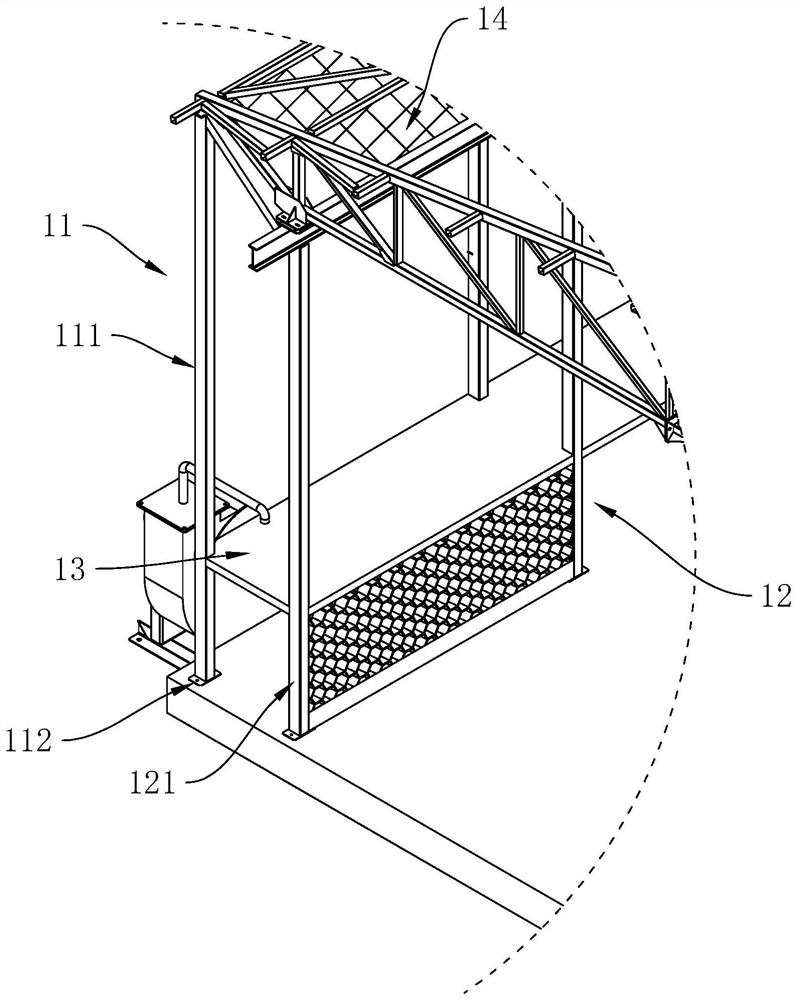

[0067] Attached to the following Figure 1-11 This application will be described in further detail.

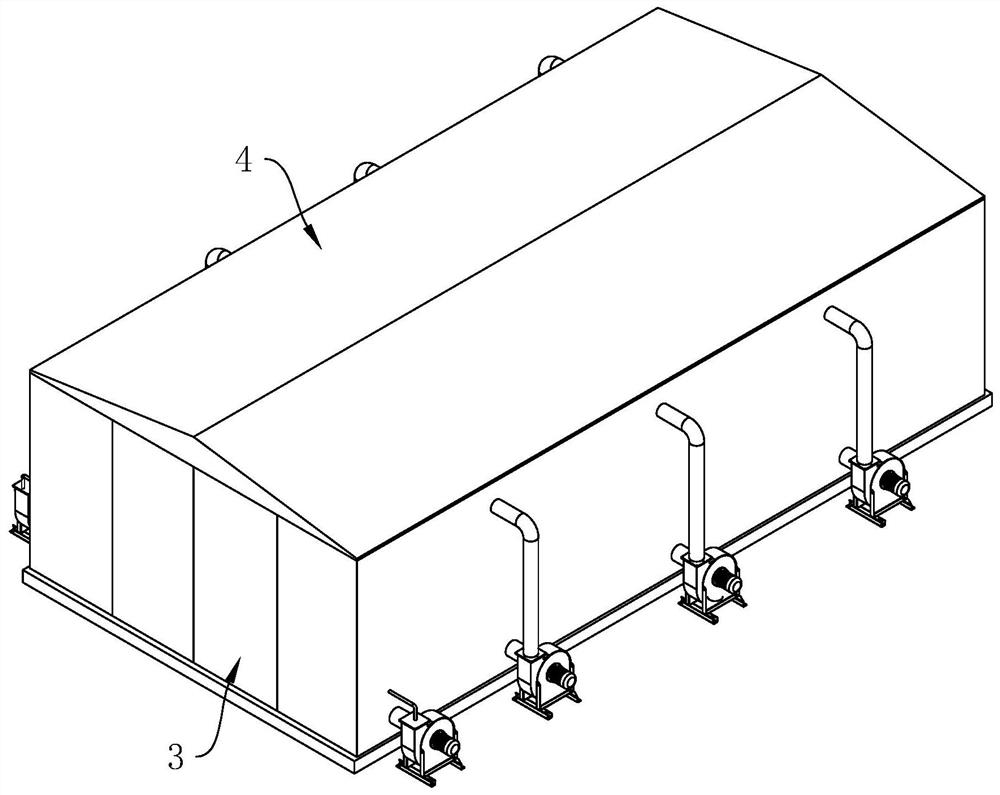

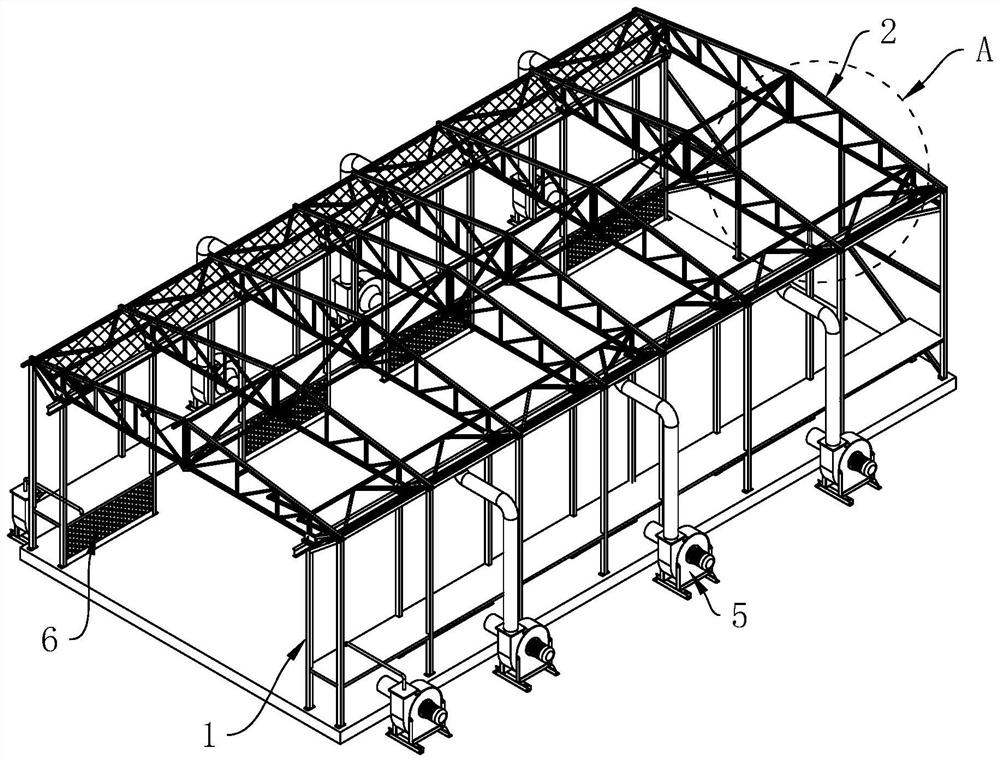

[0068] The embodiments of the present application disclose a steel structure factory building. refer to figure 1 and figure 2 , a steel structure workshop includes a steel foundation 1, a steel roof truss 2, a wall panel 3, a roof panel 4, a fan assembly 5 and a temperature control device 6, the steel foundation 1 mainly encloses the main body of the steel structure workshop, and the wall panel 3 is covered by On the inside and outside of the steel structure, it is used as the wall of the steel structure workshop. The steel roof truss 2 is installed on the steel foundation 1 to support the roof panel 4. The roof panel 4 is covered on the steel roof truss 2 to serve as the steel structure workshop. For roofing, the fan assembly 5 is used to blow compressed air into the steel structure workshop to promote air circulation. The temperature control device 6 is set on the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com