Superheater device with suspension type structure for garbage incinerator

A technology of waste incinerator and suspension structure, applied in the field of waste incineration boilers, can solve the problems of uneven force on the suspension point at the elbow of the serpentine tube, easily affected on-site work surface, affecting the service life of the superheater, etc. The top space is open, the force is uniform, and the structure is stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further description will be given below in conjunction with the embodiments shown in the accompanying drawings.

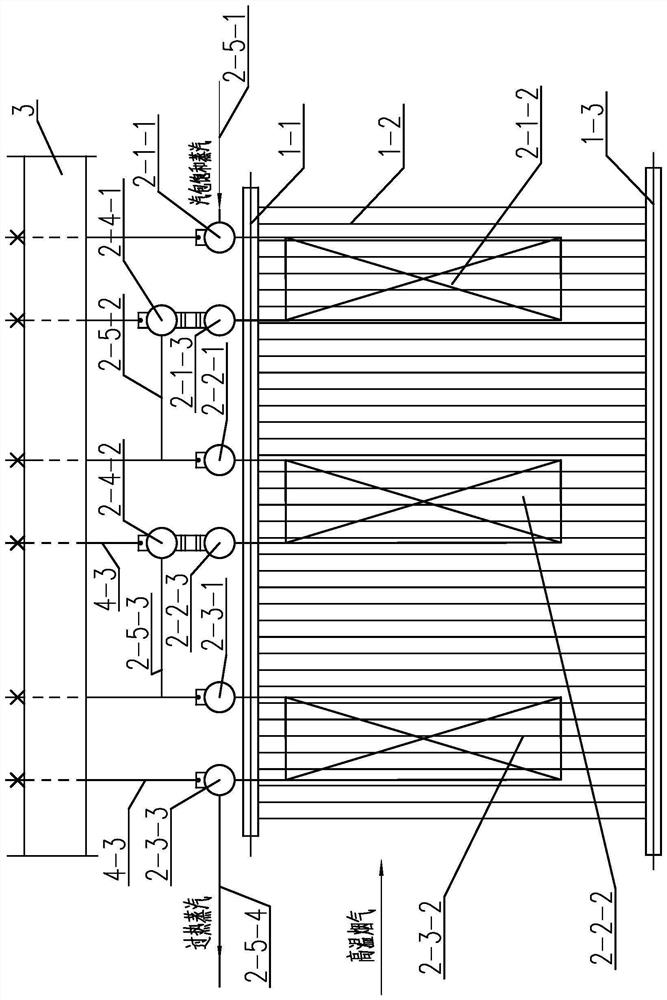

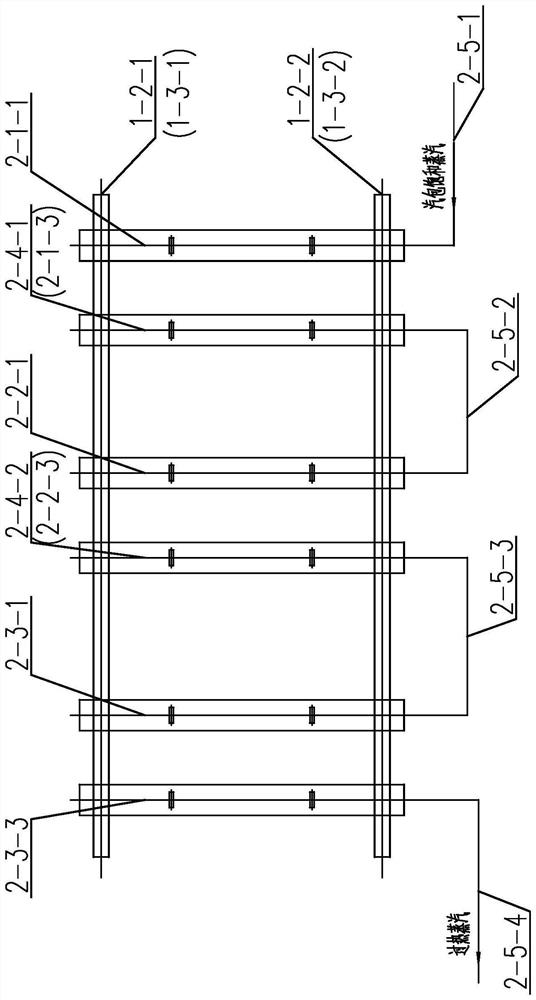

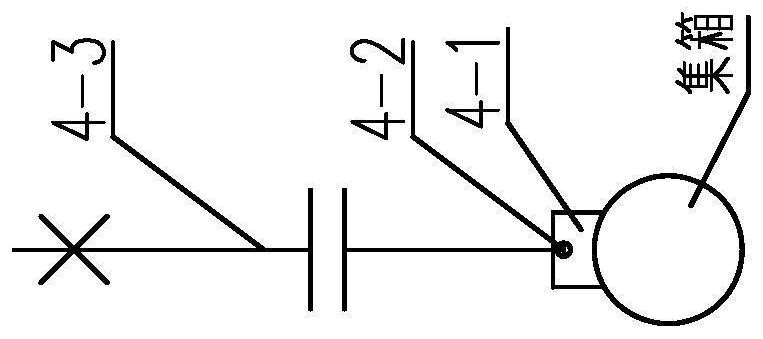

[0019] Such as Figure 1-5 The shown superheater device with suspension structure includes the top beam frame 3 fixed on the furnace body frame of the waste incinerator, the horizontal flue fixed on the top beam frame through the suspension structure (omitted in the figure), and the horizontal flue positioned on the horizontal flue. Superheater in the tunnel:

[0020] The horizontal flue includes at least one group of horizontal flue headers, and each set of horizontal flue headers includes a horizontal flue upper header group 1-1, left and right side wall water walls 1-2 and a horizontal flue lower header Groups 1-3 are formed by welding the upper and lower header groups of the horizontal flue to the two ends of the left and right side wall water cooling walls respectively; the left and right side wall water cooling walls are spliced by pipes and flat st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com