Rebar weight deviation detector

A weight deviation and detector technology, applied in instruments, weighing, measuring devices, etc., can solve the problems of simple detection method, single pertinence, imperfect detection, etc., and achieve reasonable sampling, improved flexibility, and convenient disassembly and assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

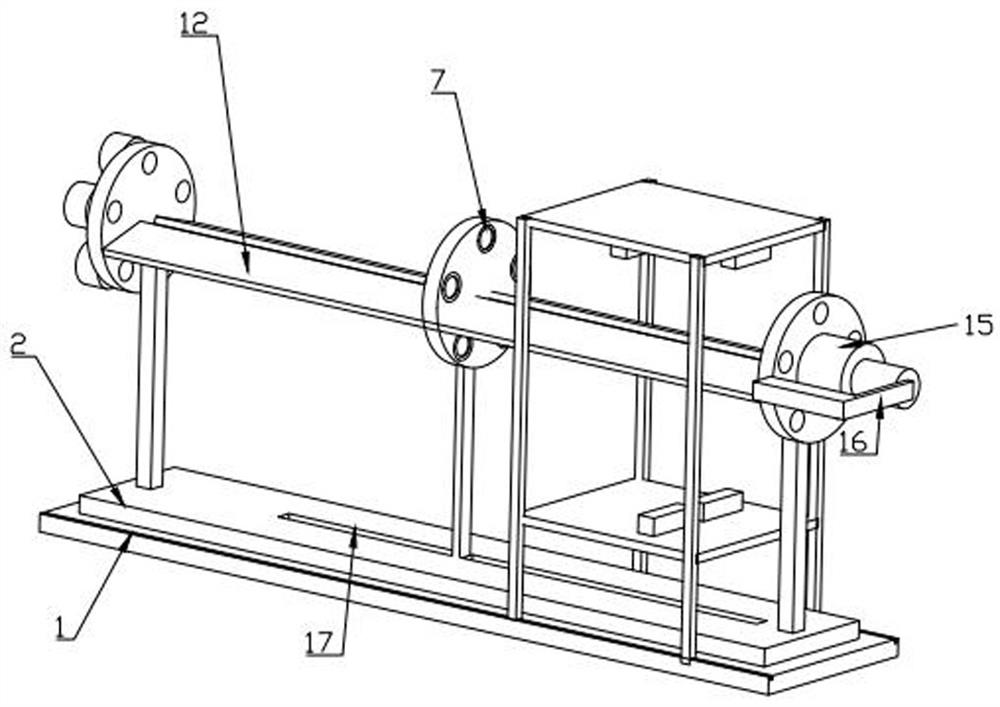

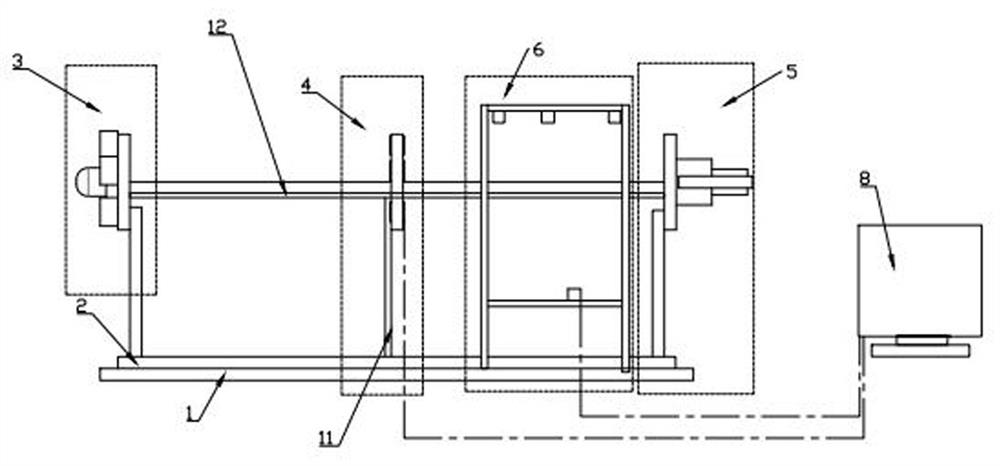

[0032] A steel bar weight deviation detector, see Figure 1 to Figure 6 , including a base 1, a weighing mechanism is installed on the base 1, and a diameter detection unit 6 is slidably installed on the base 1 at the same time, the weighing mechanism includes an elastic base 2, a driving steel support unit 3 installed on the elastic base 2, and a moving steel support unit 4 and the fixed steel bar support unit, the driving steel bar support unit 3, the mobile steel bar support unit 4 and the fixed steel bar support unit are provided with through holes for steel bar support in the same shape and position, and the mobile steel bar support unit 4 is provided with a mobile pair connection between the elastic base 2, The number of through holes is 5, distributed in a circular array. When testing, select five steel bars and insert them into each corresponding through hole in turn, and then adjust the relative positions of the driving steel bar support unit 3, the moving steel bar s...

Embodiment 2

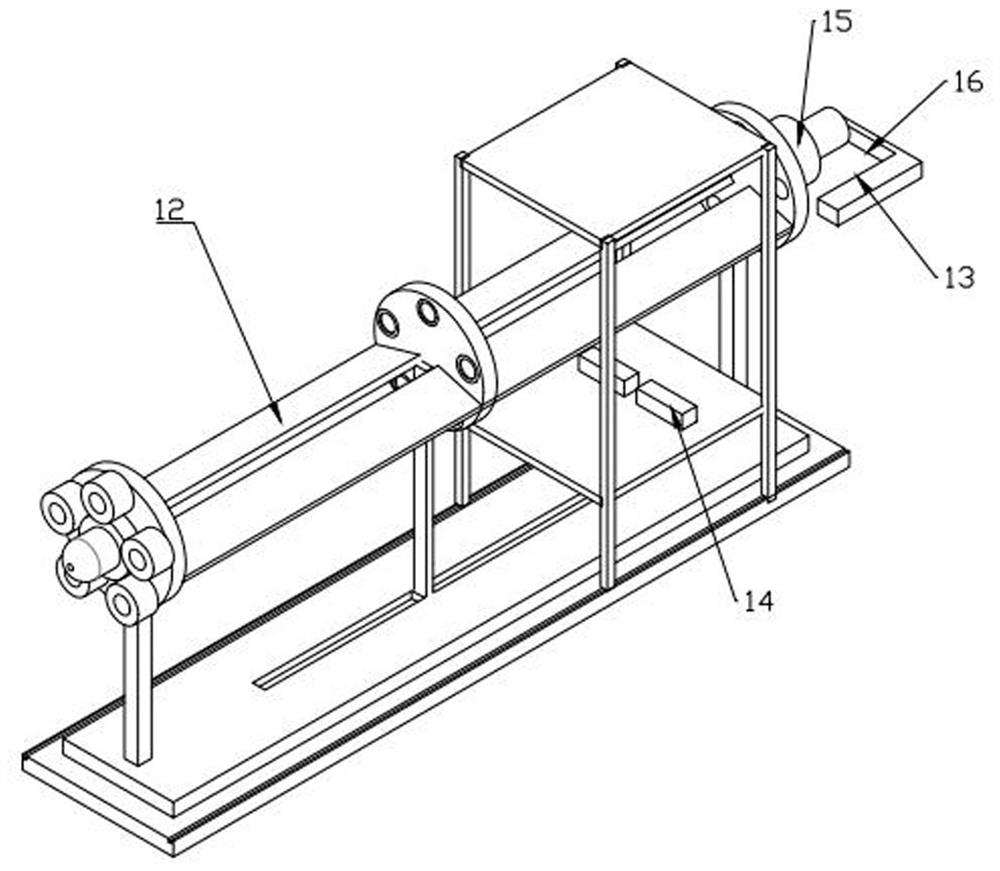

[0041]In this embodiment, the principle is the same as in Embodiment 1, the specific difference is that a rocker 16-type bracket is also provided on the outside of the fixed steel bar support unit, and a length non-contact detection device 13 is provided on the rocker 16-type bracket to measure the steel bar Stretch out the distance of the fixed steel support unit, the rocker 16 type support includes the stepped telescopic tube 15 at the bottom and the rocking bar 16 installed on the end of the telescopic tube, the telescopic tube is provided with a scale to calculate the observed stretching length. During the working process, a detection space is formed between the length non-contact detection device 13 on the rocker 16 type support and the stepped telescopic cylinder 15, which can detect the length of each protruding steel bar one by one. At the same time, if the steel bar protrudes too long , the telescopic tube can be stretched, and the working stretching and shrinking prin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com