Lithium metal negative electrode of hollow carbon spheres loaded with silver particles and solid-state battery

A lithium metal negative electrode and hollow carbon sphere technology, which is applied in the direction of lithium batteries, battery electrodes, metal processing equipment, etc., can solve the problems of lithium dendrite growth, uneven contact, interface side reactions, etc., and achieve simple preparation process and process, The effect of suppressing reverse "piercing through" and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

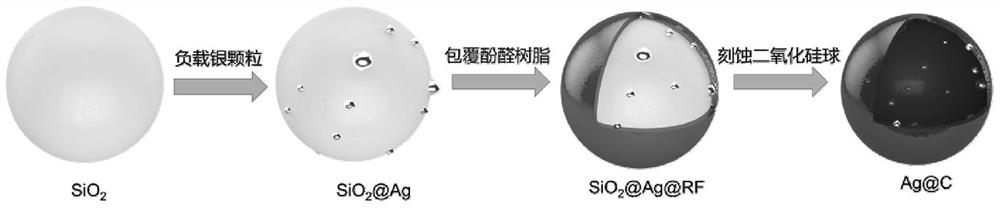

[0033] A method for preparing hollow carbon spheres loaded with silver particles according to the present invention, such as figure 1 As shown, the steps include:

[0034] 1) adding tetraethyl orthosilicate to a mixed solution of isopropanol and water for hydrolysis and polycondensation reaction to obtain silica spheres;

[0035] 2) Using the above-mentioned silica spheres as a template, using isopropanol and an aminosilane coupling agent to carry out amino functionalization on the silica spheres in the step 1 to obtain aminated silica spheres;

[0036] 3) preparing silver nano-sol;

[0037] 4) mixing the aminated silica spheres obtained in step 2 with the silver nanoparticle sol prepared in step 3, centrifuging the spheres, and finally cleaning to obtain silica spheres loaded with silver nanoparticles SiO 2 @Ag;

[0038] 5) Using resorcinol and formaldehyde solution as the precursor of the carbon source to the silica spheres SiO loaded with silver nanoparticles 2 @Ag und...

Embodiment 1

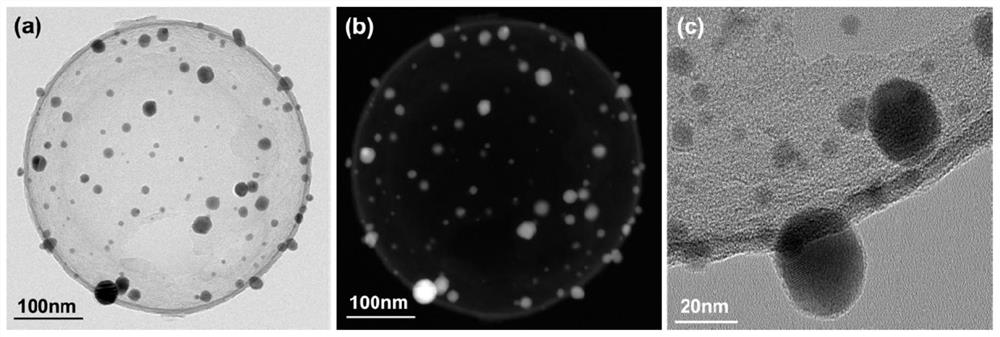

[0046] The specific preparation process of the hollow carbon spheres loaded with silver particles described in this example is as follows:

[0047] 1) Preparation of silica template: Add 8 mL of tetraethyl orthosilicate (TEOS) to a mixed solution of 80 mL of isopropanol and 12 mL of deionized water, and add 8 mL of ammonia water (25% by mass fraction, The same below) reacted for 2 hours, centrifuged and cleaned and separated, and the obtained solid was centrifuged and washed three times through isopropanol / deionized water / deionized water, and samples were collected to obtain silica spheres with a diameter of about 440nm and good dispersion.

[0048] 2) Preparation of amino-functionalized silica spheres: take the silica spheres obtained in step 1), disperse them in 100 mL of isopropanol, and then add 1 mL of 3-aminopropyltriethoxysilane (99% mass fraction , the same below) was stirred in a water bath at 60° C. for 10 h, and then the obtained solid was centrifuged with isopropan...

Embodiment 2

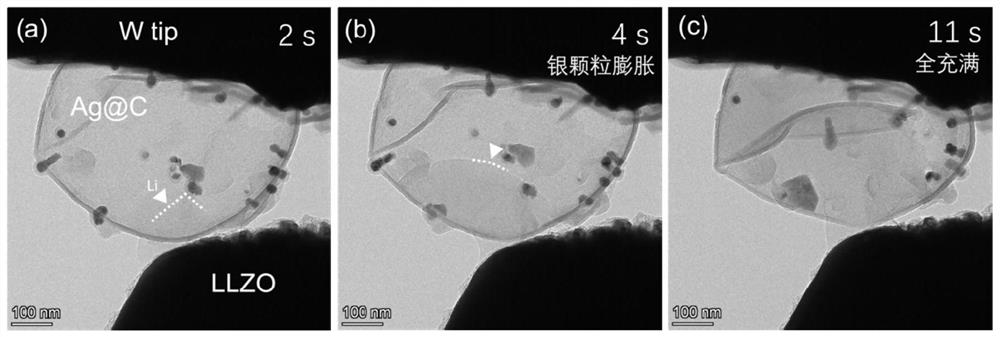

[0055] In this example, in-situ transmission was used to characterize the mechanism of action of silver-loaded hollow carbon spheres Ag@C in solid-state batteries, and to guide the deposition of lithium dendrites. The positive electrode of the in-situ transmission platform was built with Cu electrodes, and a large amount of Cu electrodes were attached to the Cu electrodes. Lithium and garnet-type solid-state electrolyte Li with particles half-embedded in lithium 6.4 La 3 Zr 1.4 Ta 0.6 o 12 (LLZTO), the negative electrode uses a W electrode, and the hollow carbon sphere Ag@C prepared in Example 1 is attached to the W electrode as a three-dimensional carbon-based framework material, and an external power supply is connected to form a closed loop, and a certain voltage is applied , garnet-type solid electrolyte Li 6.4 La 3 Zr 1.4 Ta 0.6 o 12 (LLZTO) provides a transport channel for lithium ions, and after reaching the three-dimensional carbon-based framework layer, electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap