Distribution box with automatic early warning function

An automatic early warning and distribution box technology, which is applied to the substation/distribution device casing, electrical components, substation/switch layout details, etc., can solve the problems of dust and impurity removal, manual cleaning difficulty, safety hazards, etc., to improve Stability and safety, reducing the difficulty of manual cleaning, and improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

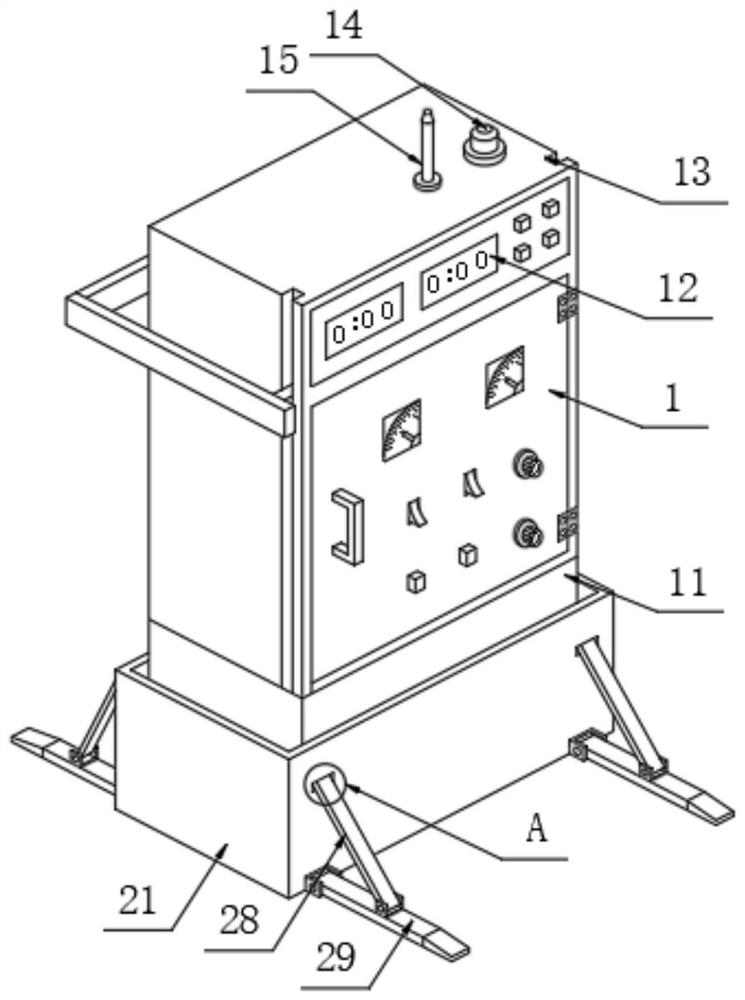

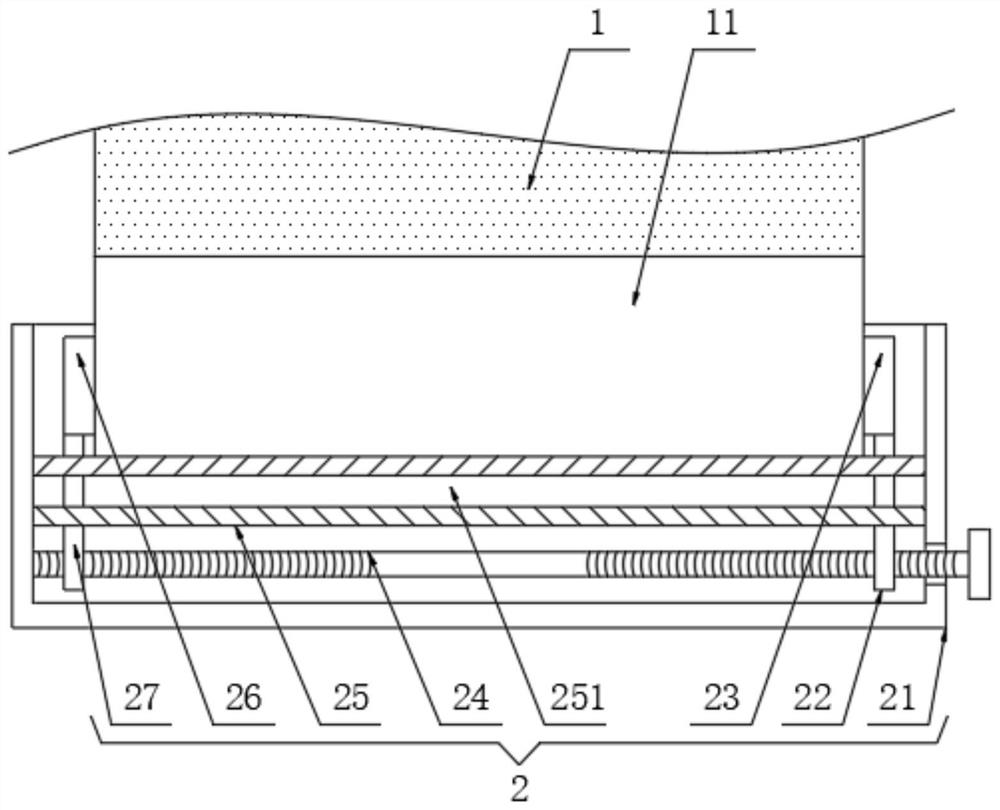

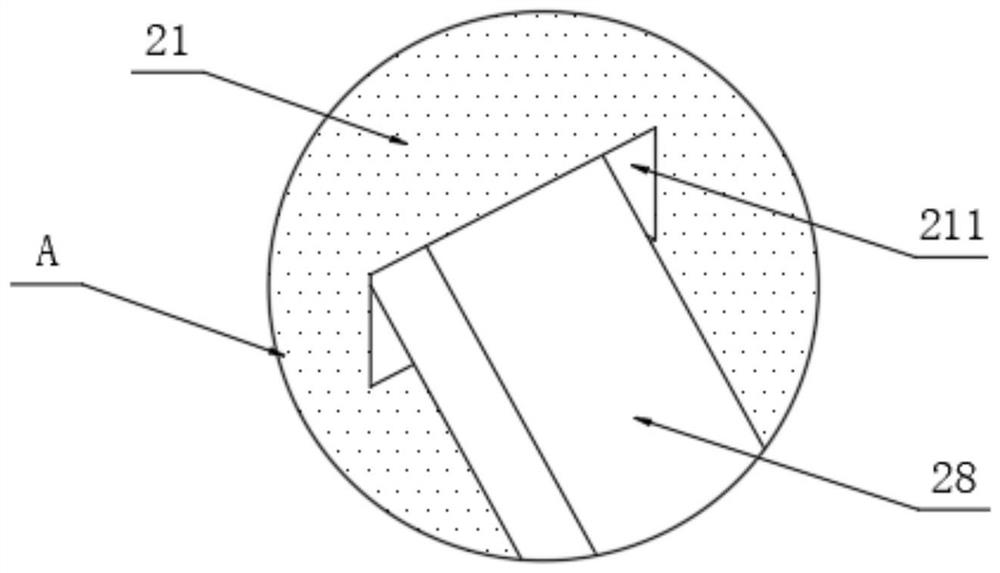

[0028] see figure 1 , Figure 4 and Figure 5 , an automatic early warning power distribution box, including a box body 1, a support base 11 is fixed on the bottom of the box body 1, a controller 12 is fixed on the front surface of the box body 1, and a top of the box body 1 is fixed with a For the alarm 14 and the smoke sensor 15, both sides of the box body 1 are longitudinally provided with limit slots 13, and a cleaning mechanism 3 is installed on the rear side of the box body 1. The cleaning mechanism 3 includes a first rod body 31, a connecting plate 32, a lock The tightening rod 321, the handle 322, the plastic plate 323, the second rod body 33, the spring 34, the first metal elastic piece 35, the roller 36 and the second metal elastic piece 39, one end of the connecting plate 32 is fixed with the first rod body 31, and the connecting plate The other end of 32 is fixed with a second rod body 33, two locking rods 321 are movably penetrated through the interior of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com