Preformed cage type early warning anti-condensation power distribution cabinet

An anti-condensation, power distribution cabinet technology, applied in substation/distribution device casings, alarms, instruments, etc., can solve problems such as reducing condensation and dripping, it is difficult to achieve service life, and reduce condensation dripping on electronic devices. effects on components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

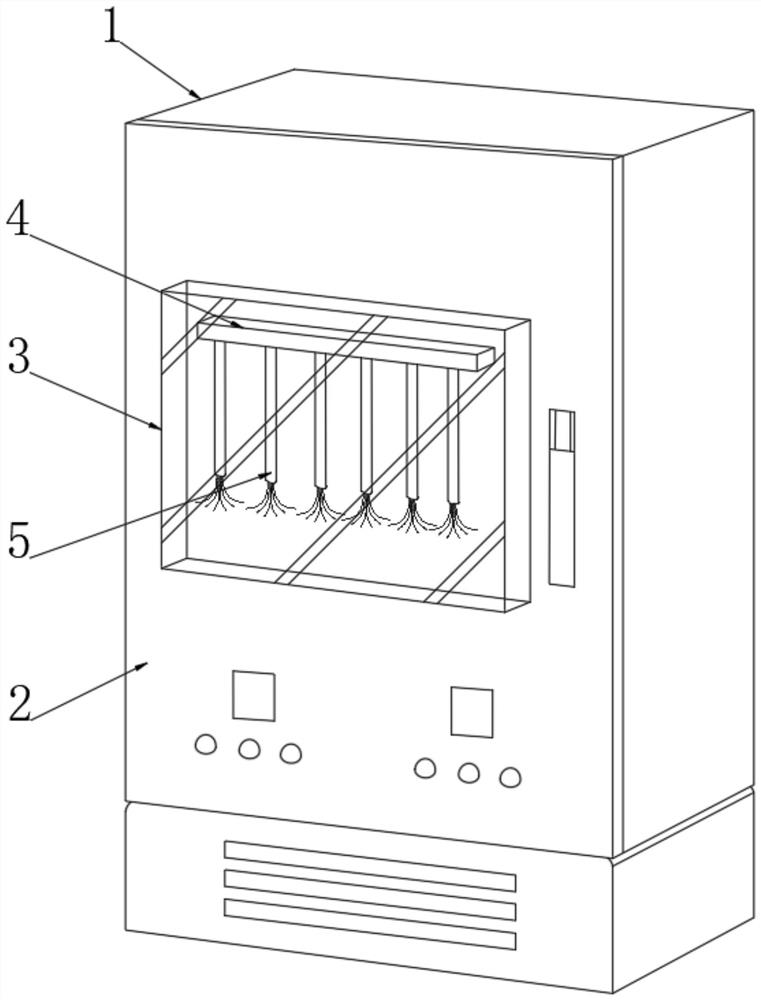

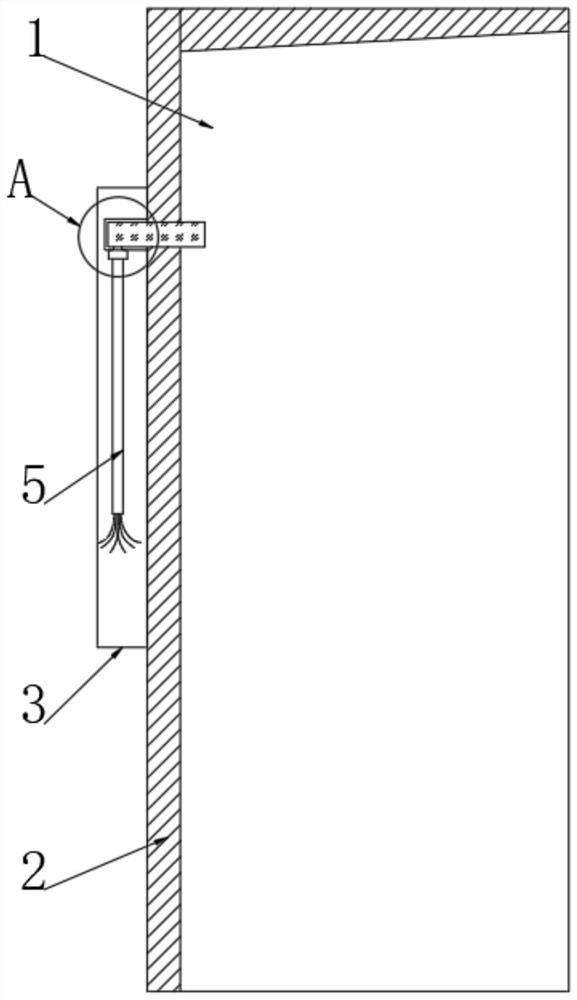

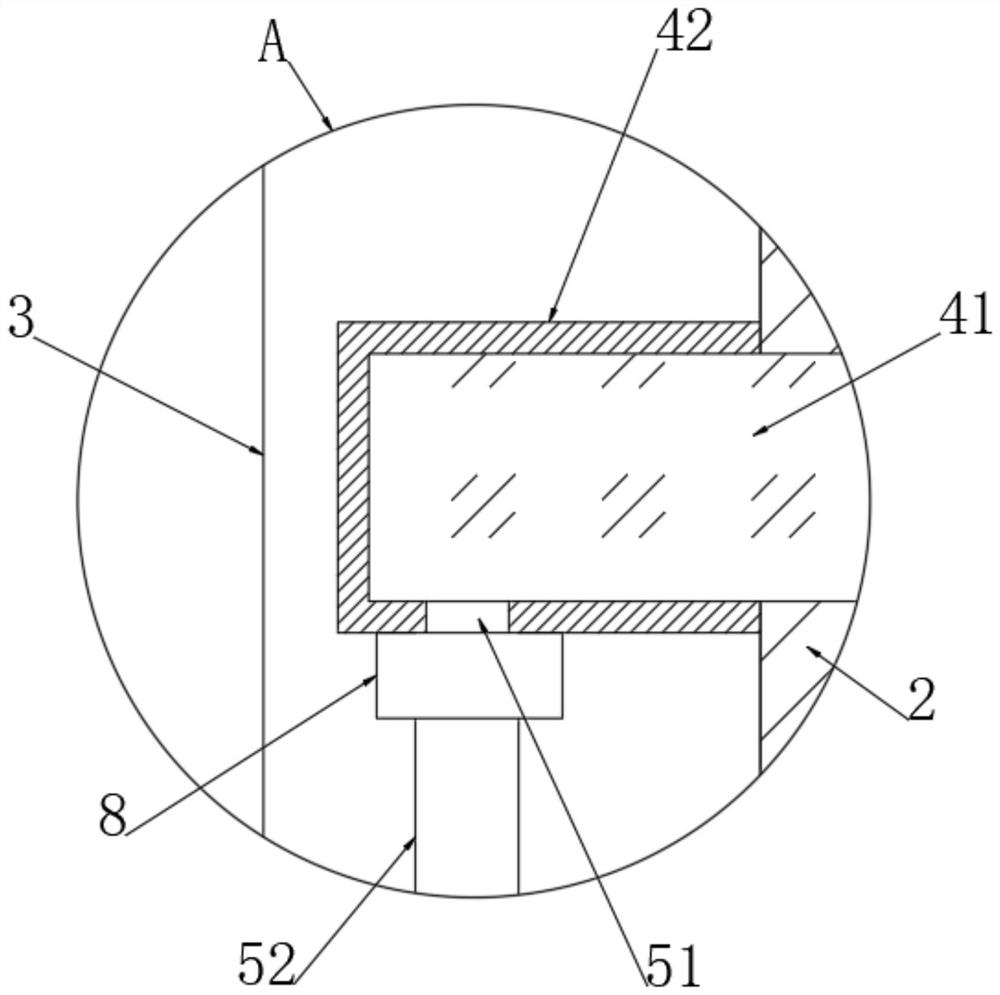

[0036] see Figure 1-2 , a pre-formed cage-type early warning anti-condensation power distribution cabinet, including a cabinet body 1, the top of the cabinet body 1 is inclined, and the side facing the cabinet door 2 is low, and the side away from the cabinet door 2 is high, the cabinet body 1 A cabinet door 2 is installed on the cabinet door 2, and the outer end of the cabinet door 2 is clamped with an outer cover 3. A strip-shaped hole is cut on the cabinet door 2, and a dew guide plate 4 is connected in the strip-shaped hole, such as image 3 The dew guide plate 4 includes an outer cladding 41 inserted through the bar-shaped hole and an inner dew-absorbing layer 42 fixedly connected to the opening of the bar-shaped hole facing the outer cover 3. The inner dew-absorbing layer 42 is wrapped around the cabinet door 2 The outer surface of the outer cladding layer 41, the outer cladding layer 41 is made of water-absorbing material, and the inner dew-absorbing layer 42 is a hard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com