Latex collecting device for mountain rubber garden

A collection device and latex technology, applied in the fields of application, agriculture, forestry, etc., can solve the problems of labor, labor and material resources, latex collection rush, etc., and achieve the effect of improving collection efficiency and avoiding washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

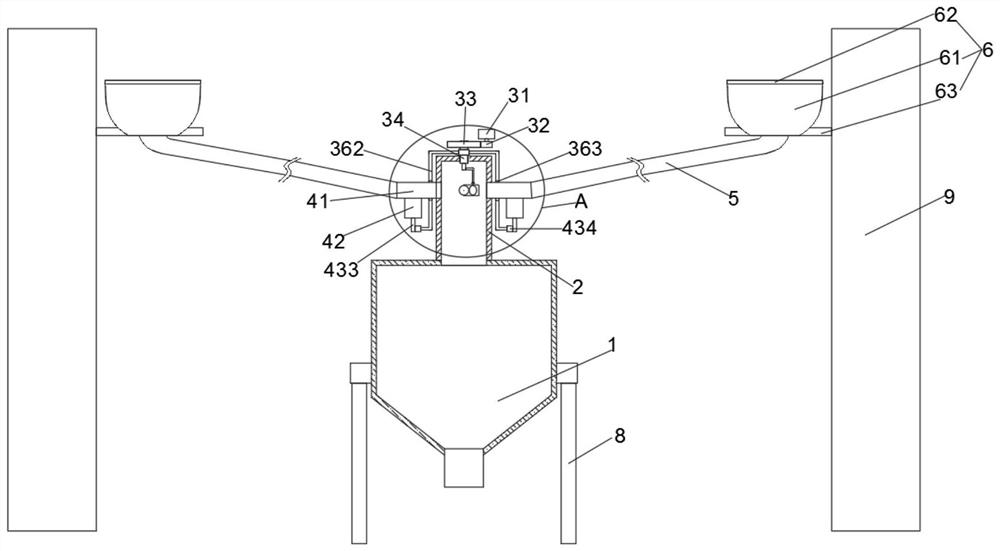

[0026] see Figure 1 to Figure 5 A latex collection device for mountain rubber gardens provided by the present invention includes a temporary storage tank 1, a confluence cylinder 2, a rain sensor and a drive assembly 3, the confluence cylinder 2 communicates with the temporary storage tank 1, and the The upper periphery of the confluence cylinder 2 is connected with several flow guide components 4 for latex flow diversion and rainwater discharge, and several flow guide components 4 are connected with corresponding drainage tubes 5, and the free ends of the drainage tubes 5 are connected with the rubber bowl 61 assembly 6. The rubber bowl 61 component 6 is fixed under the rubber tree 9 drainage sheet, the rubber bowl 61 component 6 can collect latex, and drain the latex of multiple rubber trees 9 into the confluence tube 2 through the diversion tube, without manual work The latex of each rubber tree 9 is collected, the rain sensor is electrically connected to the controller, a...

Embodiment 2

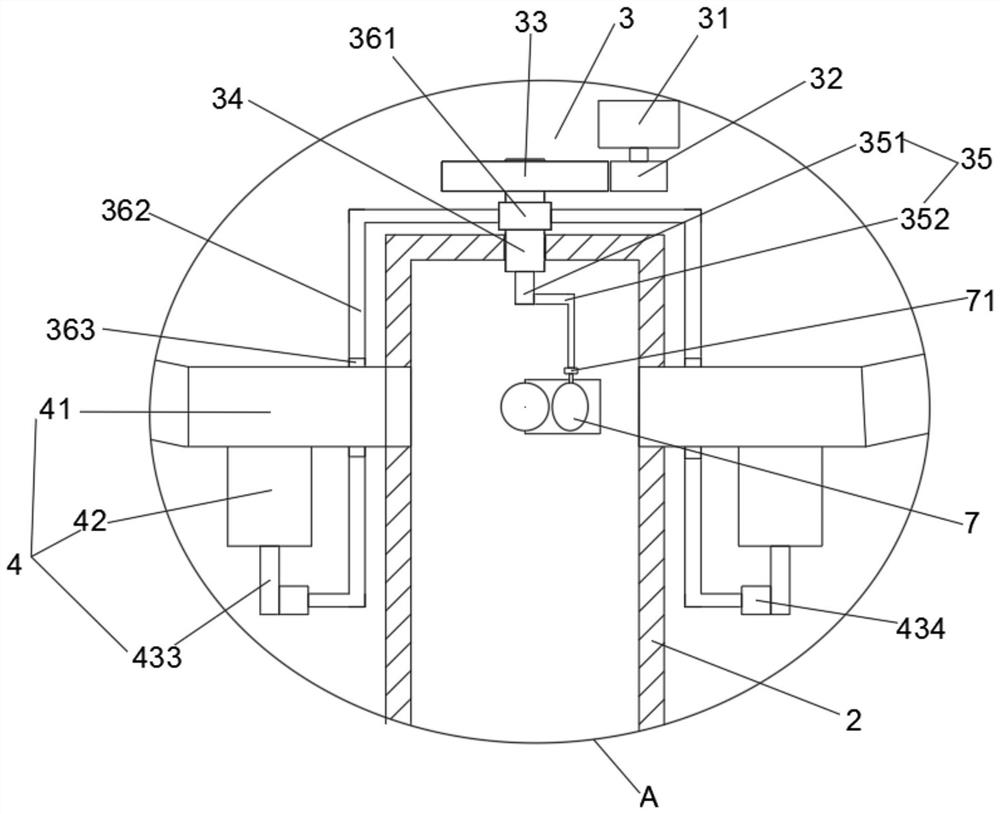

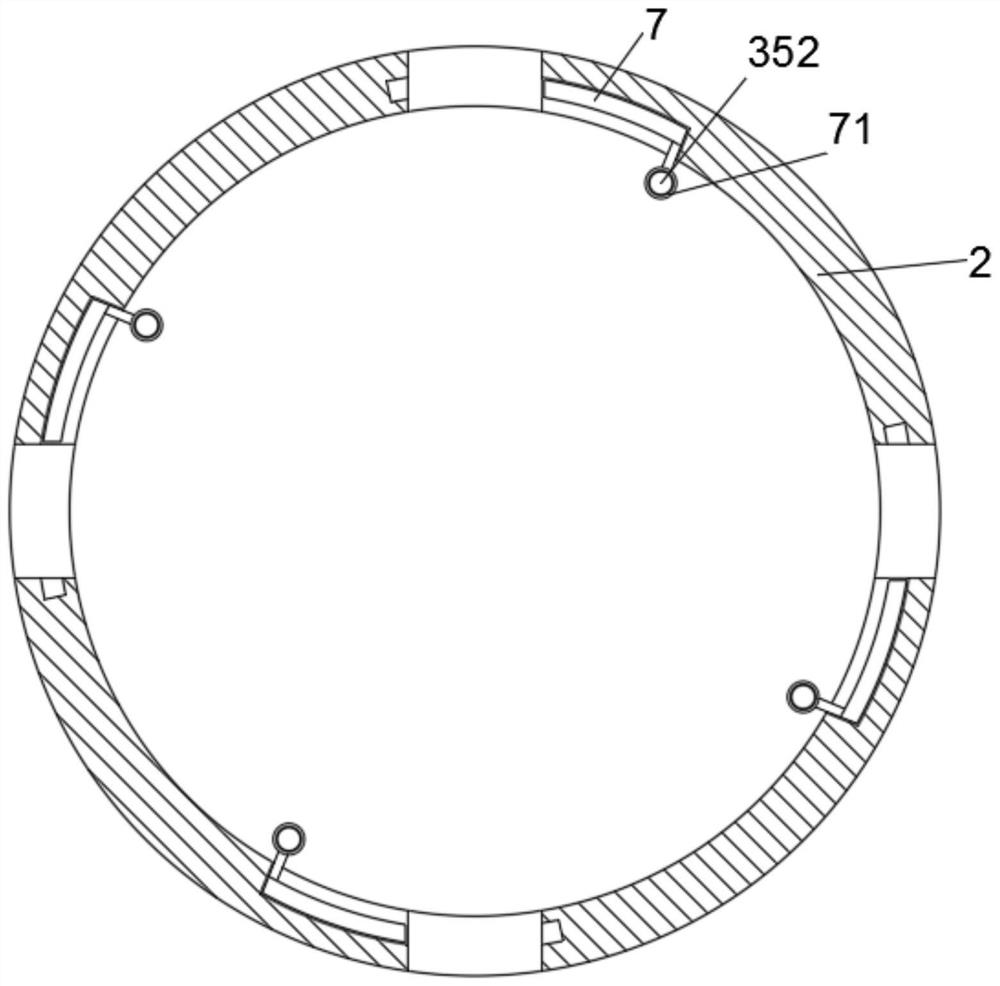

[0031] see Figure 1 to Figure 5The difference between this embodiment and Embodiment 1 is that the pushing frame 35 includes a connecting rod 351 and a plurality of push rods 352, one end of the connecting rod 351 is connected to the rotating shaft 34, and the free end of the connecting rod 351 is connected to the rotating shaft 34. Several push rods 352 are connected, the sealing plate 7 is slidably connected in the manifold 2 , and the sealing plate 7 is connected to the push rods 352 through a connecting ring 71 . The rotation of the connecting rod 351 drives the push rod 352 to rotate, and the rotating push rod 352 pushes the sealing plate 7 to slide through the connecting ring 71, and the sliding sealing plate 7 seals the communication port of the manifold 2; and the toggle frame 36 includes a collar 361 and several Z-shaped toggle rods 362, the collar 361 is sleeved on the rotating shaft 34, several Z-shaped toggle levers 362 are connected with the collar 361, and the Z...

Embodiment 3

[0034] see Figure 1 to Figure 6 The difference between this embodiment and Embodiment 1 is that the rubber bowl 61 assembly 6 includes a rubber bowl 61, a filter screen 62 and a mounting base 63, the mounting base 63 is fixed on the rubber tree 9, and the rubber bowl 61 is fixed on On the mounting seat 63, the filter screen 62 is connected to the top of the plastic bowl 61, the plastic bowl 61 communicates with the drainage pipe 5, and the filter screen 62 is connected to the top of the plastic bowl 61, which can play a role in The filtration effect of the latex prevents impurities from blocking the drainage tube 5 through the rubber bowl 61. Simultaneously, in order to collect more rubber trees 9 latex, the drainage tube 5 includes a drainage main pipe 51 and several drainage branch pipes 52. One end of the drainage main pipe 51 It communicates with the diversion assembly 4, the free end of the drainage main pipe 51 communicates with several of the drainage branch pipes 52, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com