Automatic operation siphon filter tank convenient to monitor

A siphon filter, automatic operation technology, applied to loose filter material filters, filter separation, gravity filters, etc., can solve problems affecting normal water supply, uncontrollable time, insufficient filtered water, etc., to increase water treatment capacity , Avoid wasting water and save water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

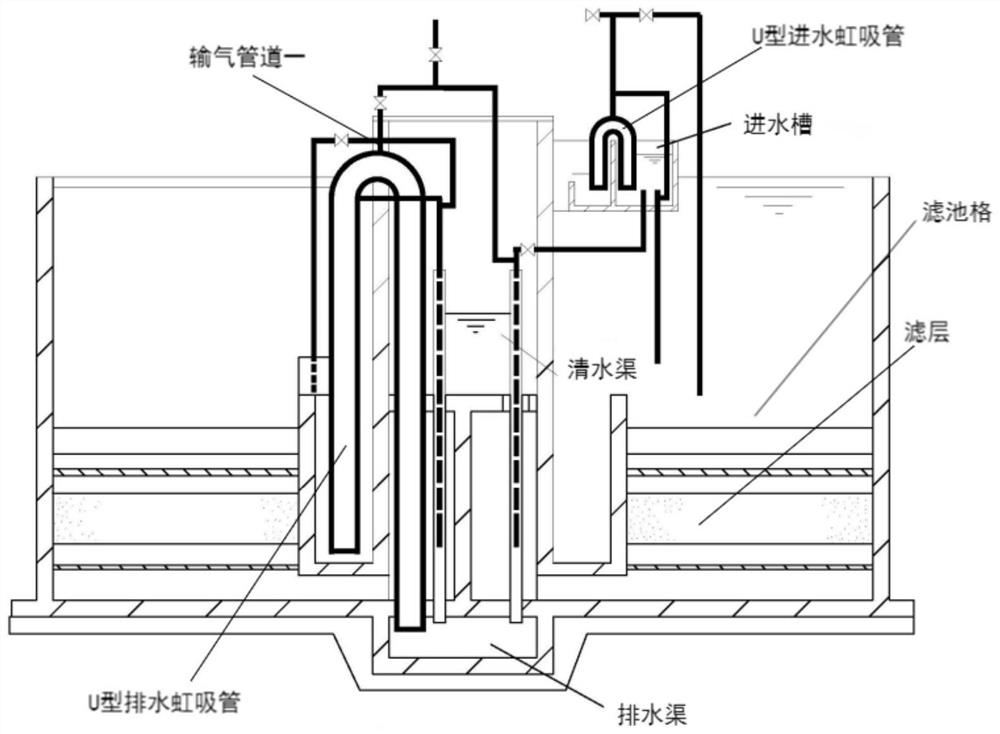

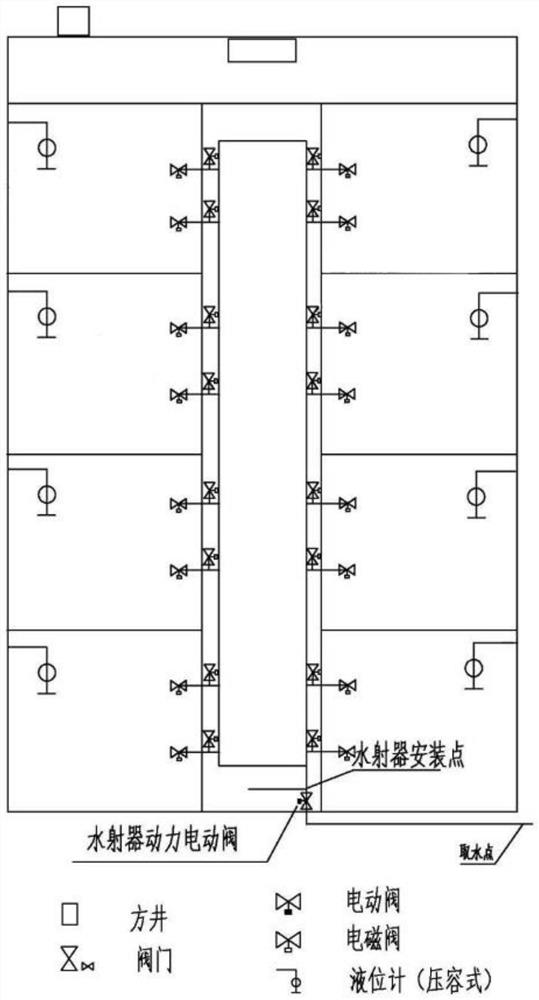

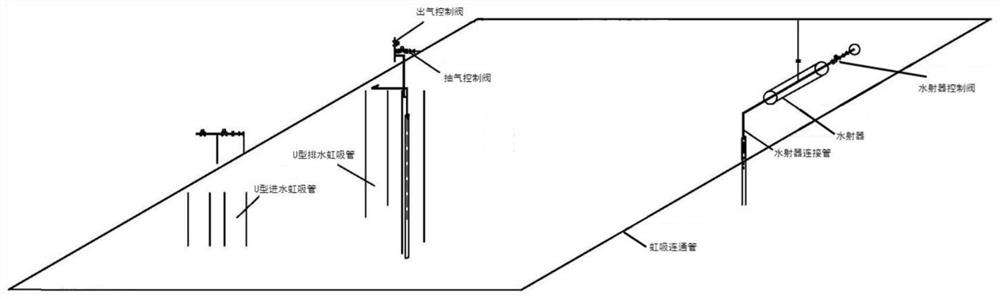

[0028] A self-operating siphon filter for easy monitoring, such as Figure 1-4 As shown, it includes the filter body, the water inlet fixed on the outer wall of the filter body by bolts, several filter cells with the same structure inside the filter body, the water outlet well fixed on the outer wall of the filter body and control system, the top outer wall of the filter grid is provided with a water distribution tank; the inner wall of each filter grid is equipped with a U-shaped drainage siphon, a U-shaped water inlet siphon, a water inlet tank, a water inlet weir, a water distribution pipe and a filter layer; the inner wall of each filter grid is provided with a monitoring unit, and the monitoring unit communicates with the control system.

[0029] The monitoring part is composed of a pressure-capacity liquid level gauge for monitoring the operating state of each filter cell and an alarm for alarming the water level of the filter cell.

[0030] The monitoring part also inc...

Embodiment 2

[0036] A self-operating siphon filter for easy monitoring, such as Figure 1-4 As shown, in order to ensure the stability of the backwashing operation; this embodiment makes the following improvements on the basis of Embodiment 1: the monitoring part also includes a control module for automatically deploying the backwashing sequence of each filter cell in the filter body , A quality monitoring module for automatically detecting the backwashing effect of filter cells and a cleaning duration module for matching the next backwashing time according to different backwashing effects of filter cells;

[0037]The control module includes a timing block for automatically calculating the backwashing interval of each filter grid. According to the rules of the timing block, the control module automatically regulates the sequence of backwashing of each filter cell, so that only one filter cell is backwashed each time, ensuring that the total water output of other filter cells meets the flus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com