Winding and transporting device for textile fabric

A transportation device and a technology for textile fabrics, applied in the field of rewinding transportation devices for textile fabrics, can solve problems such as hidden dangers, unguaranteed tension, and high labor intensity, and achieve the advantages of avoiding potential safety hazards, improving processing safety, and reducing labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

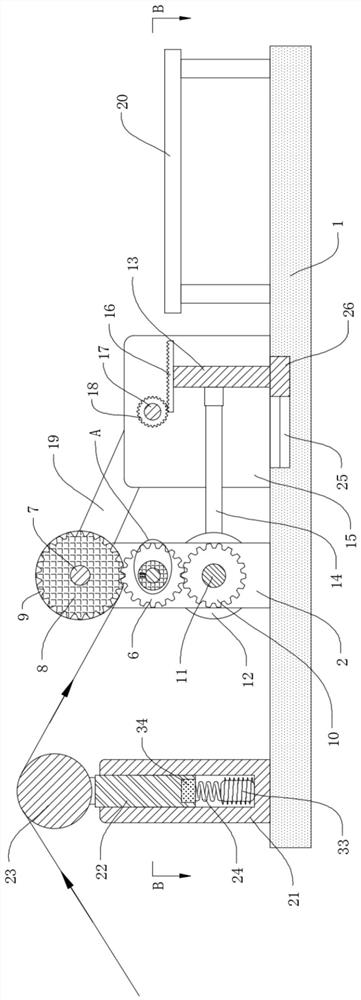

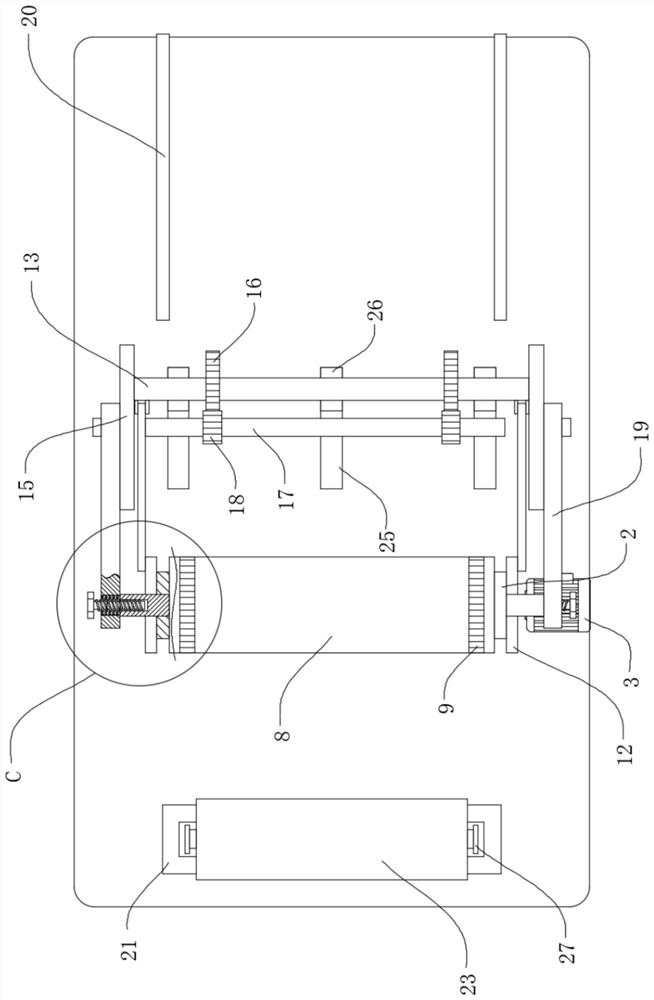

[0029] refer to Figure 1-8 , a rolling transportation device for textile fabrics, including a base 1, two first plate parts 2 and a second plate part 15 are welded on the upper surface of the base 1, and a servo motor 3 is fixedly connected to the upper surface of the base 1 through a bracket. The servo motor 3 can precisely control the direction of rotation and the angle of rotation, which is a prior art, and will not be described in detail here. A winding transport mechanism is arranged between the two first plates 2;

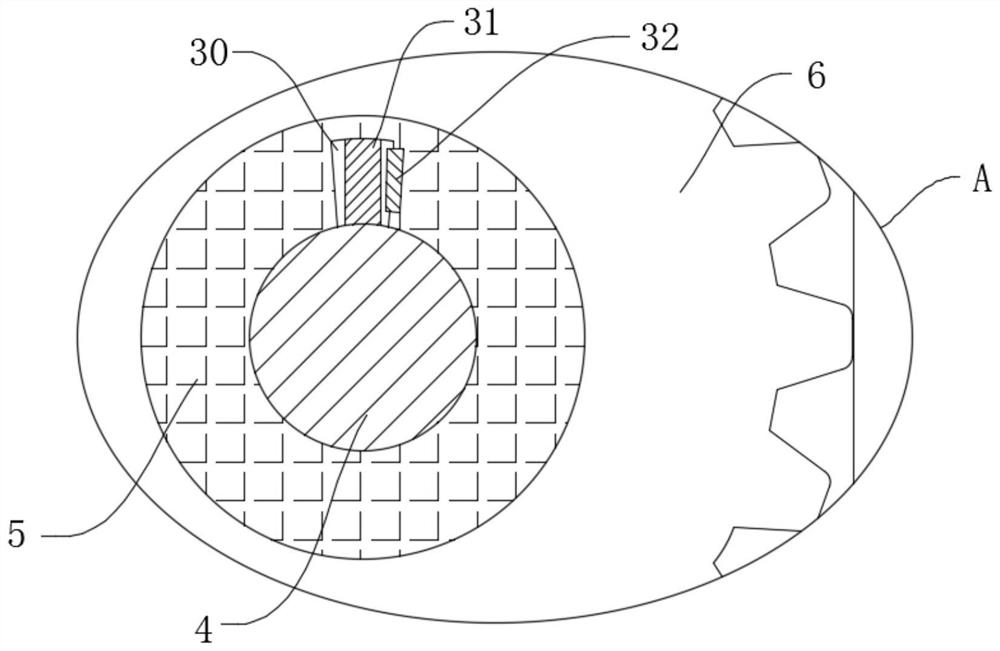

[0030]The winding transport mechanism includes a first rotating shaft 4 and a third rotating shaft 11, the first rotating shaft 4 and the third rotating shaft 11 are connected to the first plate 2 through bearings for rotation, and the first rotating shaft 4 is fixedly connected to the output shaft of the servo motor 3 A second rotating shaft 5 is rotatably connected between the two first plates 2 through bearings, and the first rotating shaft 4 and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com