Combination bearing and combination bearing with encoder

A combined bearing and encoder technology, which is applied in the direction of rigid support, bearing components, shafts and bearings of bearing components, can solve the problems of non-integration and poor combination precision, reduce processing links, ensure inherent precision, and beautiful appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

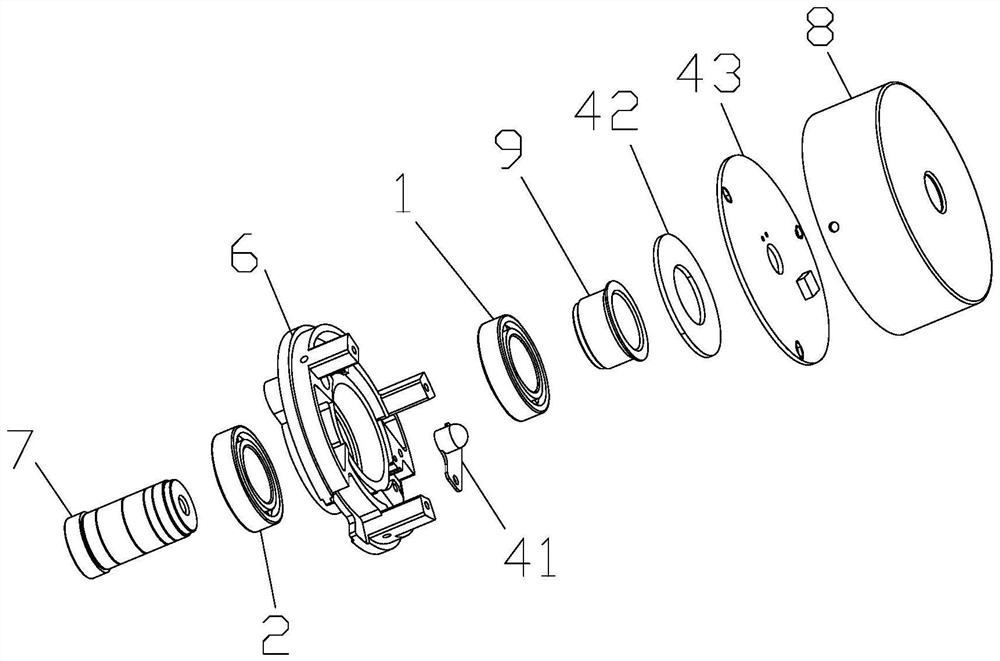

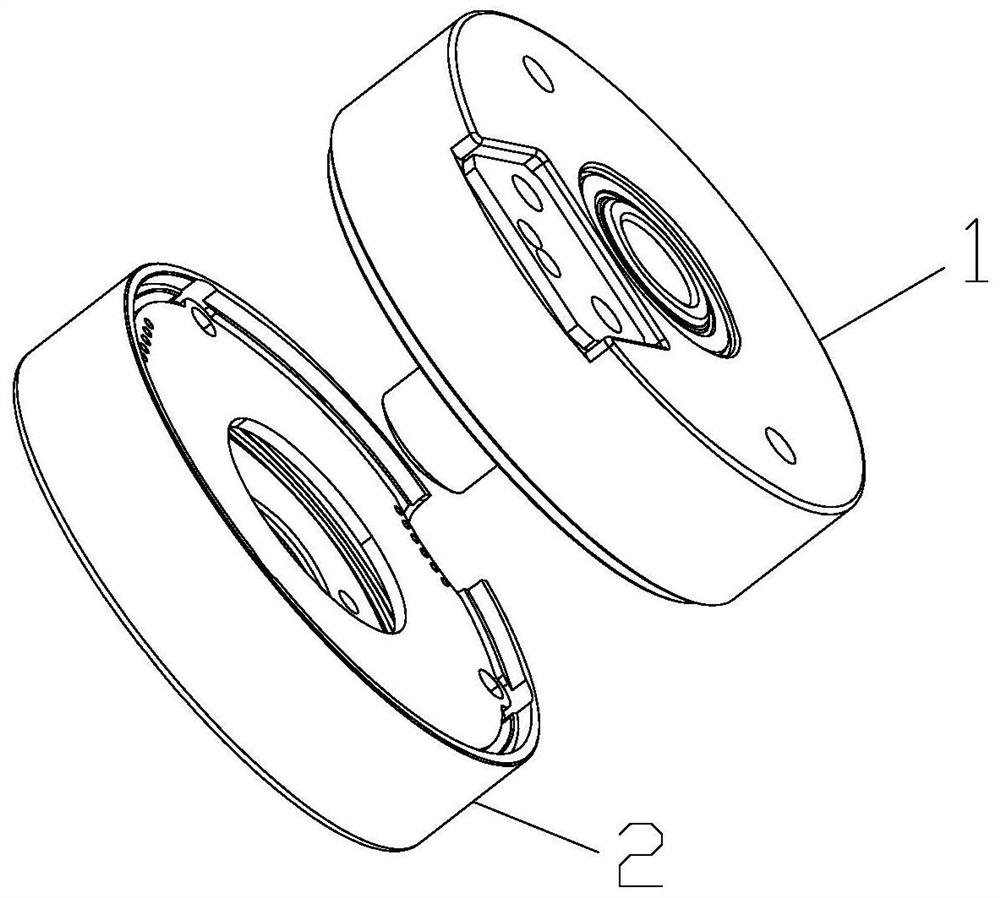

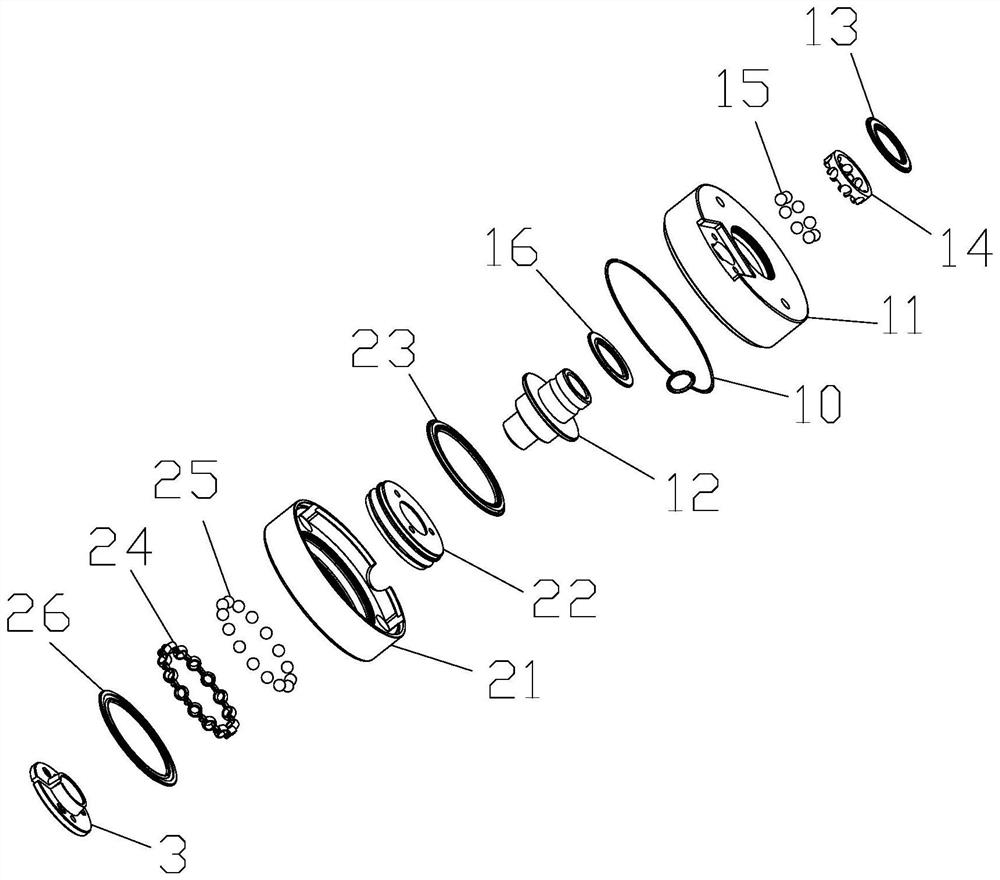

[0042] Combined bearing, including upper bearing 1 and lower bearing 2, upper bearing 1 includes upper bearing outer ring 11, upper bearing inner ring 12, first sealing ring 13, first cage 14, first steel ball 15 and second sealing ring 16 , the first cage 14 evenly separates the first steel balls 15 and places them in the grooves of the upper bearing outer ring 11 and the upper bearing inner ring 12 .

[0043] One end of the upper bearing inner ring 12 is an inner ring member 121, which is matched with the upper bearing outer ring 11; the lower bearing 2 includes the lower bearing outer ring 21, the lower bearing inner ring 22, the third sealing ring 23, the second cage 24, the second The second steel ball 25 and the fourth sealing ring 26, the second cage 24 evenly separates the second steel ball 25, and places them in the groove of the lower bearing outer ring 21 and the lower bearing inner ring 22, and the inner ring part 121 is essentially the inner ring of the bearing. R...

Embodiment 2

[0049] Combined bearing, its structure is based on Embodiment 1, the shape of the inner hole wall of the lower bearing inner ring 22 matches the outer shape of the locking sleeve 3, and the radial contact surface between the lower bearing inner ring 22 and the outer periphery of the locking sleeve 3 is On the end face 222 , the locking sleeve 3 is locked on the end face 222 of the inner ring 22 of the lower bearing.

Embodiment 3

[0051] Combined bearing, its structure is on the basis of embodiment 1, the first locking installation hole 34 is provided on the locking sleeve body, the corresponding second locking installation hole 221 is provided on the lower bearing inner ring 22, the first locking installation hole 34 is connected with the second locking installation hole 221 through a nut.

[0052] The side edge of the upper bearing outer ring is provided with a first concave-convex step 111, and the side edge of the lower bearing outer ring is provided with a second concave-convex step 211. The upper bearing outer ring 11 and the lower bearing outer ring 21 pass through the first concave-convex step 111 and the second The concave-convex steps 211 are closely matched, and the concave-convex fit is fastened. A rubber washer 10 is provided between the first concave-convex step 111 of the upper bearing outer ring and the second concave-convex step 211 of the lower bearing outer ring.

[0053] The locking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com