Electric power inspection operation system integrated with intelligent wearable equipment and inspection process

A smart wearable, power inspection technology, applied in the parts of TV systems, TVs, color TVs, etc., can solve the problems of low inspection efficiency, single function, complicated operation, etc., to improve the efficiency and intelligence of inspection operations. degree, system design is reasonable, and the effect of enhancing equipment information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

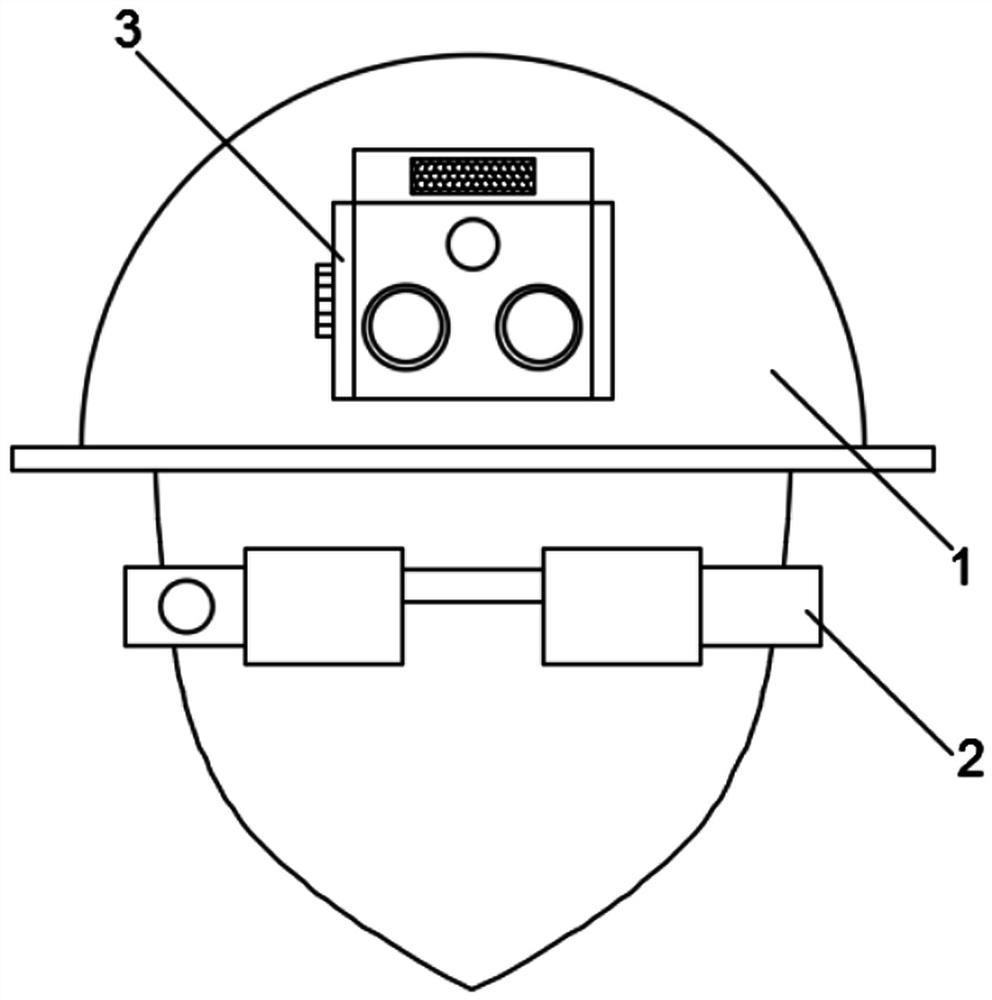

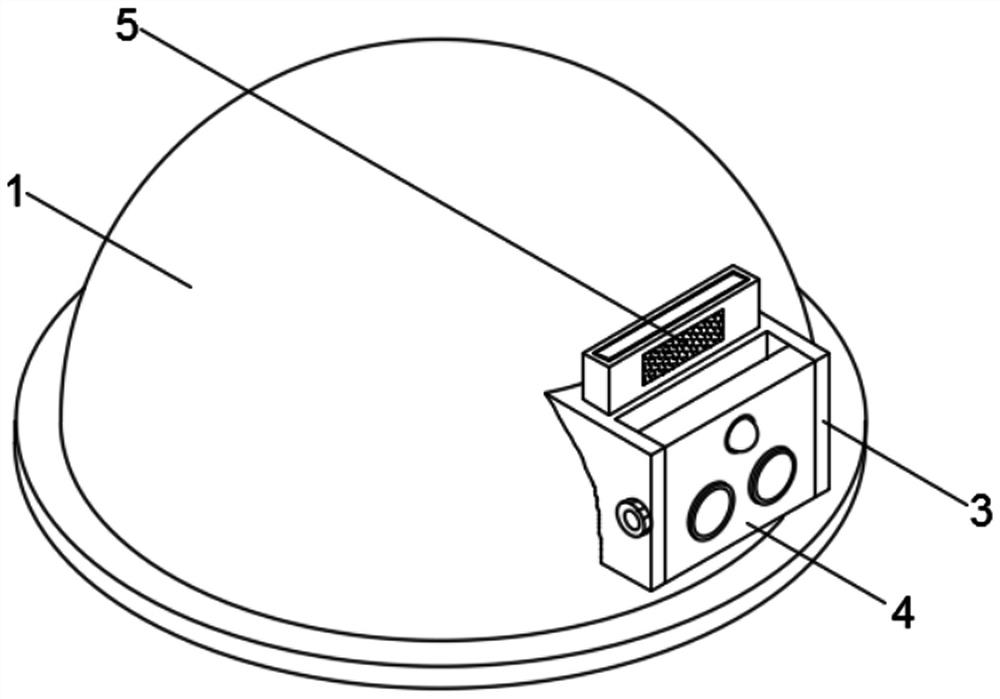

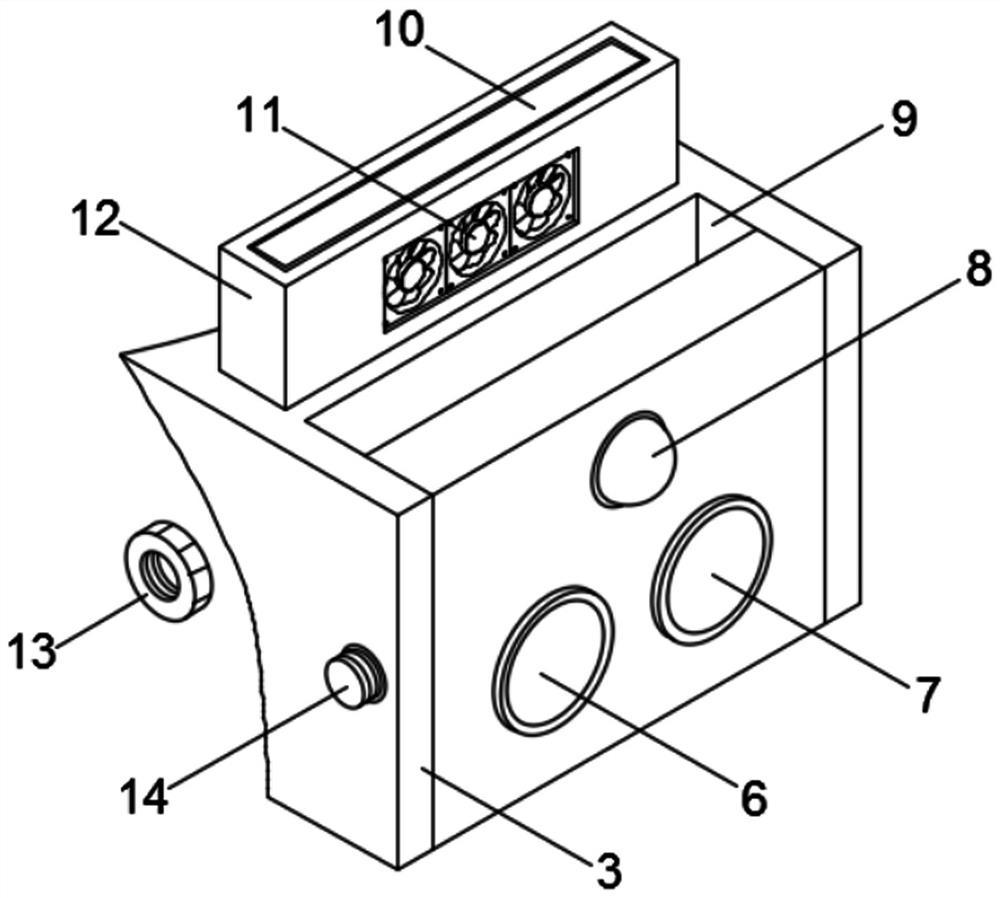

[0053] The present invention also provides an embodiment in which the power inspection process that fuses intelligent wearable equipment is in addition to the equipment in Example 1, and the field inspection equipment also includes a smart bracelet 15. Handheld Patrol Terminal 16, Device ID Tag 17, Expert Auxiliary Analysis System 18. Such as Figure 4 Distance Figure 4 It is a schematic diagram of the inspection operation system of the present invention. Wherein, the field inspection equipment is wirelessly connected to the intelligent wear host 12, the cloud device image device 10, and the expert auxiliary analysis system 18, wherein the field inspection equipment and the intelligent wear host 12 can communicate data interaction through wireless mode, and implement two-way connect. The intelligent wear host 12 is also connected to the device ID tag 17 to read information. The expert auxiliary analysis system 18 is an expert auxiliary analyzer.

[0054] The present invention is ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com