Sub-cooking system and sub-cooking method

A cooking method and coding technology, which is applied in the field of intelligent fast food processing equipment, can solve the problems of high cost and low automation of code management, and achieve the effects of high automation, convenient tracking, and accurate identification and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

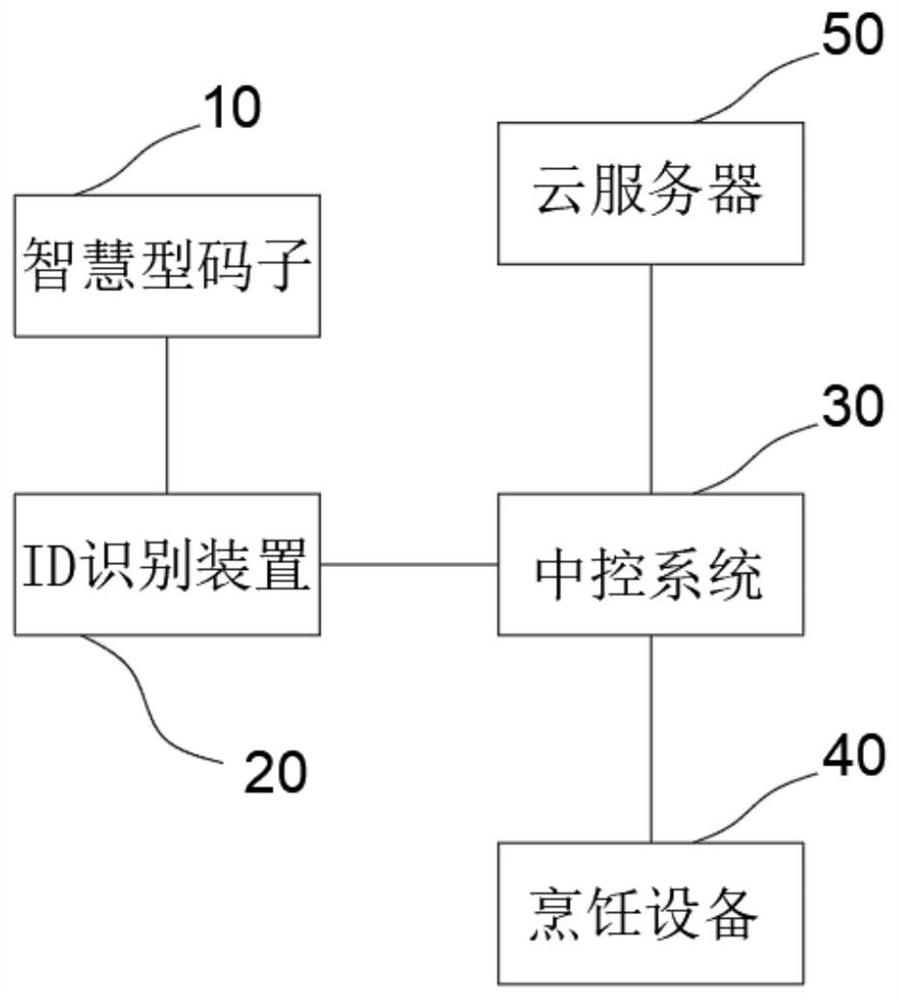

[0036] see figure 1 , the present embodiment provides a code cooking system, which is applied in intelligent fast food equipment, and the code cooking system is used for managing and cooking the code in the set food.

[0037] Specifically, the code cooking system includes a smart code 10 , an ID code identification device 20 , a code cooking device 30 , a central control system 40 and a cloud server 50 .

[0038] The smart code 10 is the finished packaging form of the code, which specifically includes a code container, such as a code bag or a code box. Dish codes are sealed in the code container, such as braised beef in brown sauce, fried pork with pepper and the like. The outer surface of the code container is provided with a code ID code, such as a one-dimensional code or a two-dimensional code. The one-dimensional code or two-dimensional code can be printed directly on the outer surface of the code container at the factory, or can be pasted on the surface of the code conta...

Embodiment 2

[0065] The difference between this embodiment and Embodiment 1 is that the tag ID code set on the outer surface of the tag container can also be an RFID code, and the RFID code not only includes the function of storing tag ID information, but also has a near-field trigger function.

[0066] Specifically, the RFID code is detachably connected to the code container, for example, a clip is set, the RFID code is set in the clip, and then clamped together on the code container. When in use, the clip is removed and then put into a cooking device, and the cooking device is triggered to cook the code through near-field interaction.

Embodiment 3

[0068] The difference between this embodiment and the first embodiment is that: the code sub-ID code contains two or more types of food code sub-identity information.

[0069] It is easy to understand that the menu size is contained in the size container, and a plurality of small packages can also be arranged in the size container, so that one size container can accommodate multiple types of menu sizes. The code sub-identity information of various menu codes is all set on the outer surface of the code sub-container, so when the ID code identification device 20 scans the code sub-container, multiple code sub-identity information can be obtained.

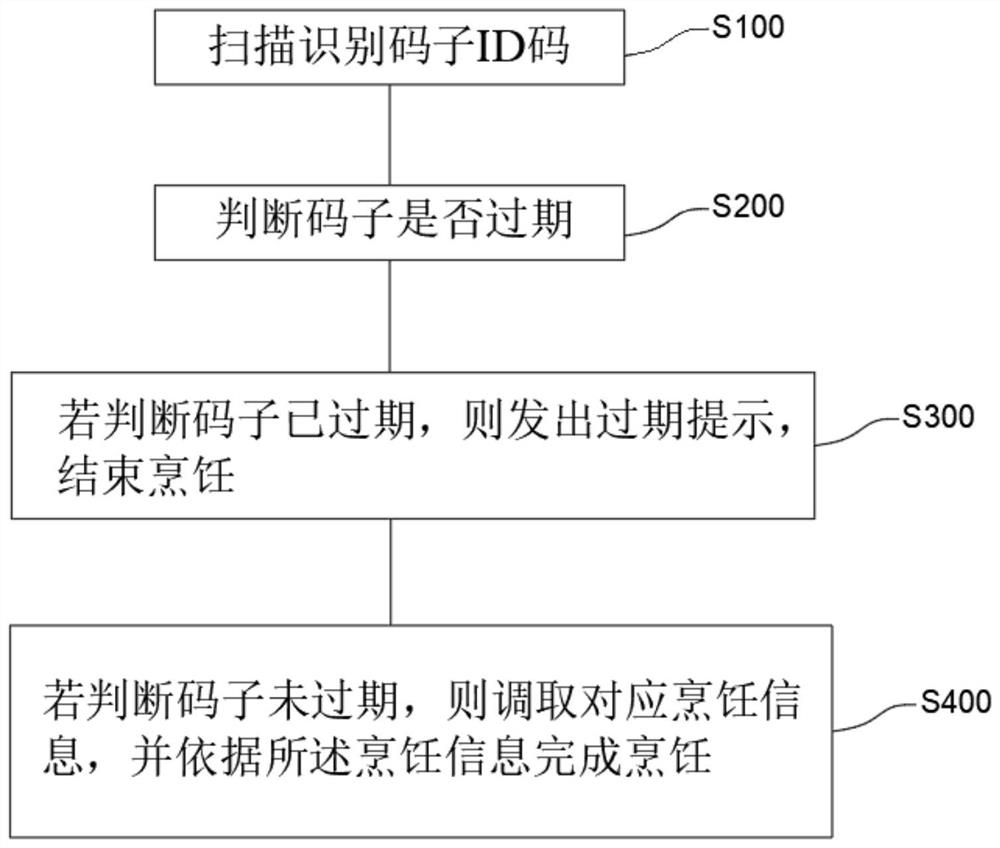

[0070] When judging food expiration, it is necessary to judge each code sub-identity information separately. As long as one of the code sub-identity information is determined to be expired, the entire smart code sub-10 cannot be eaten, and the central control system 40 will issue an expiration prompt to end this time. Cooking; if all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com