Carbon neutralization emission treatment system for building construction

A treatment system and building construction technology, applied in the direction of chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of affecting the sealing of the box, the small spraying range, and the cover plate is easy to be knocked, so as to improve the sputtering effect, the effect of enhancing the neutralizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

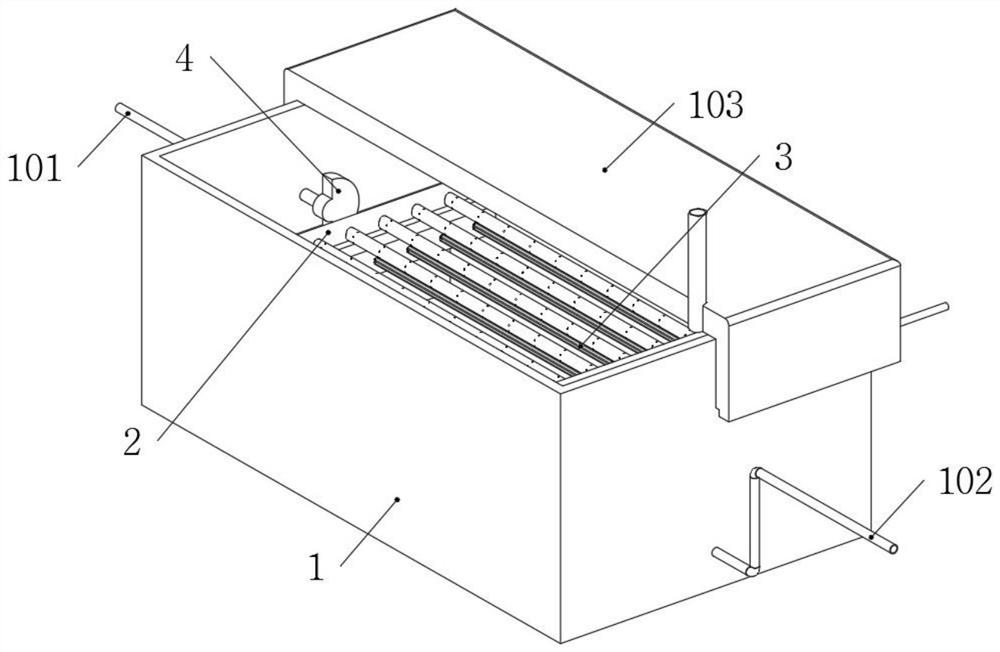

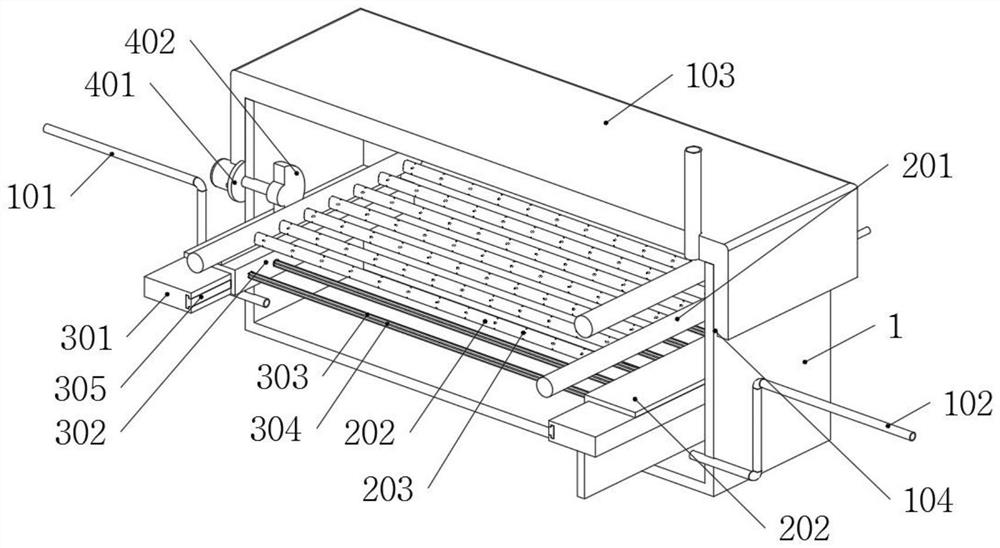

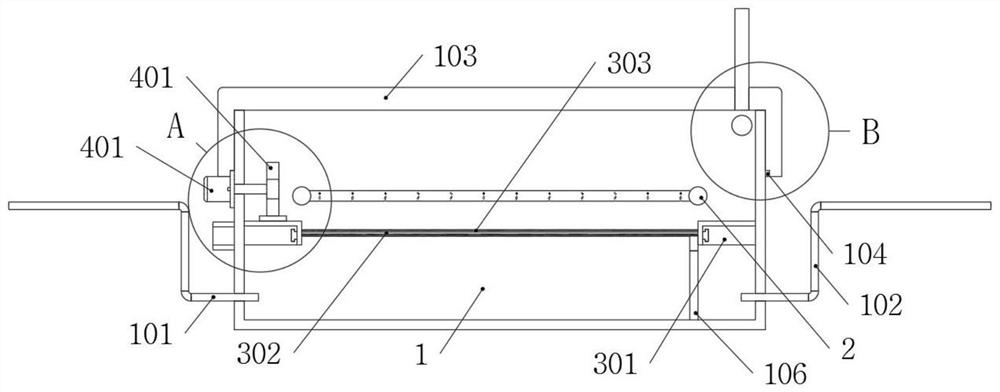

[0037] Example: Please refer to Figure 1 to Figure 8 :

[0038] The present invention proposes a construction carbon neutral emission treatment system, including: a box body 1, a neutralization part 2, an auxiliary part 3 and a driving part 4;

[0039] The box body 1 is fixed on the mounting frame, and the box body 1 is connected with an air intake pipe 101, and the box body 1 is also connected with a water suction pipe 102;

[0040] The neutralization part 2 is composed of a connecting pipe 201, a spray pipe 202 and a spray hole 203, and the connecting pipe 201 is installed on the box body 1, and the connecting pipe 201 is connected with the water supply pump;

[0041] The auxiliary part 3 is composed of a sliding track 301, a sliding seat 302, an auxiliary rod 303, a protrusion 304 and an elastic block 305, and there are two sliding tracks 301, and the two sliding tracks 301 are fixedly connected to the box body 1 by bolts. on the inner wall;

[0042] The driving part 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com