Internal decontamination type cone crusher for mine

A cone crusher and crusher technology, applied in cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of reducing crushing efficiency, ore blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

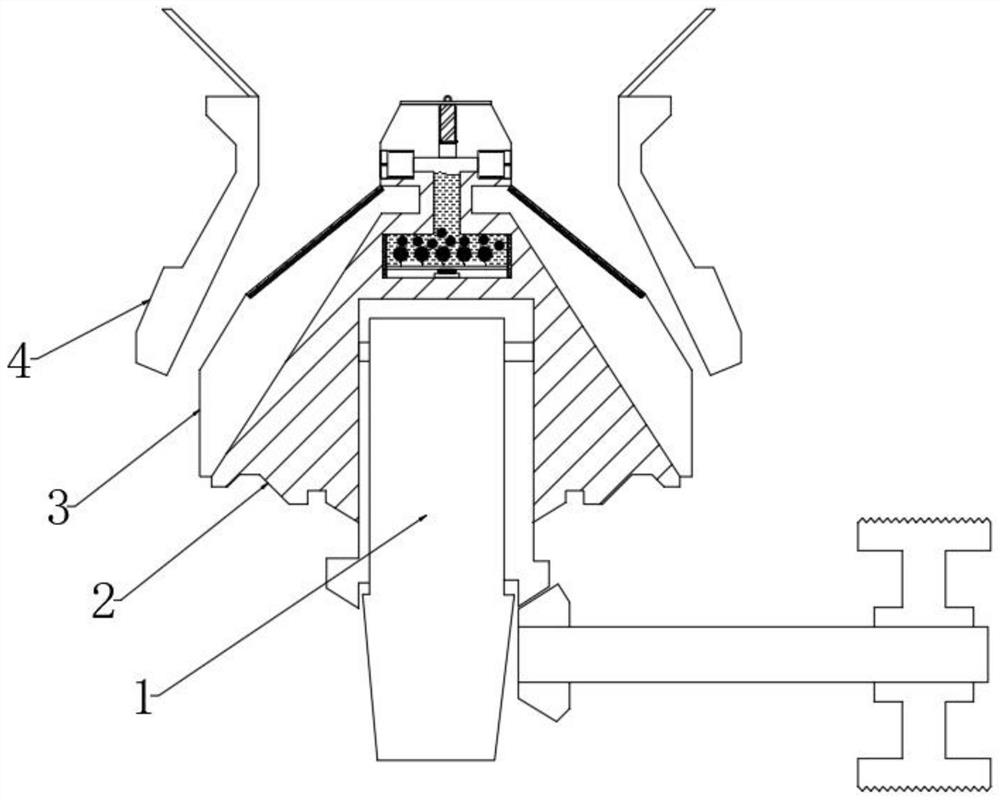

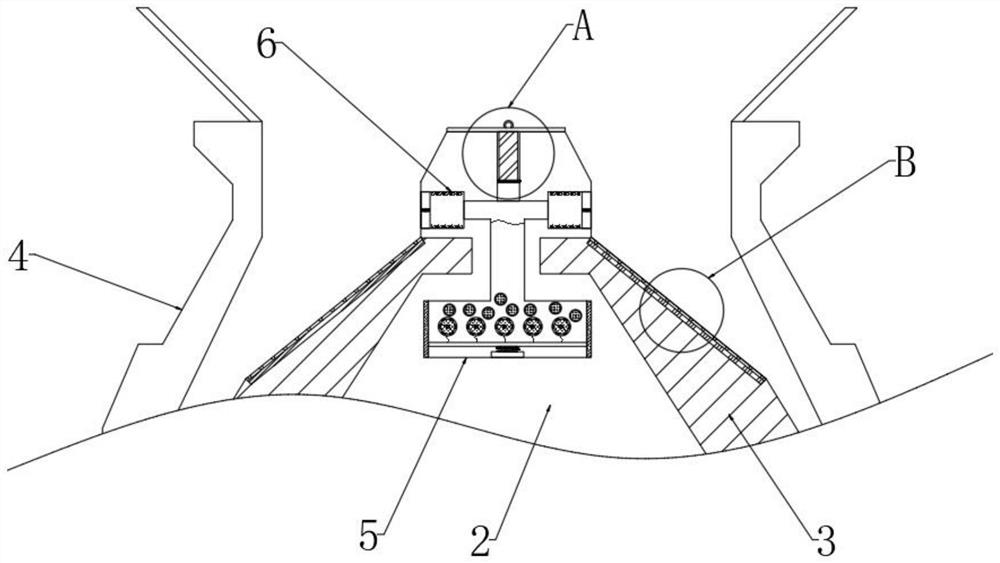

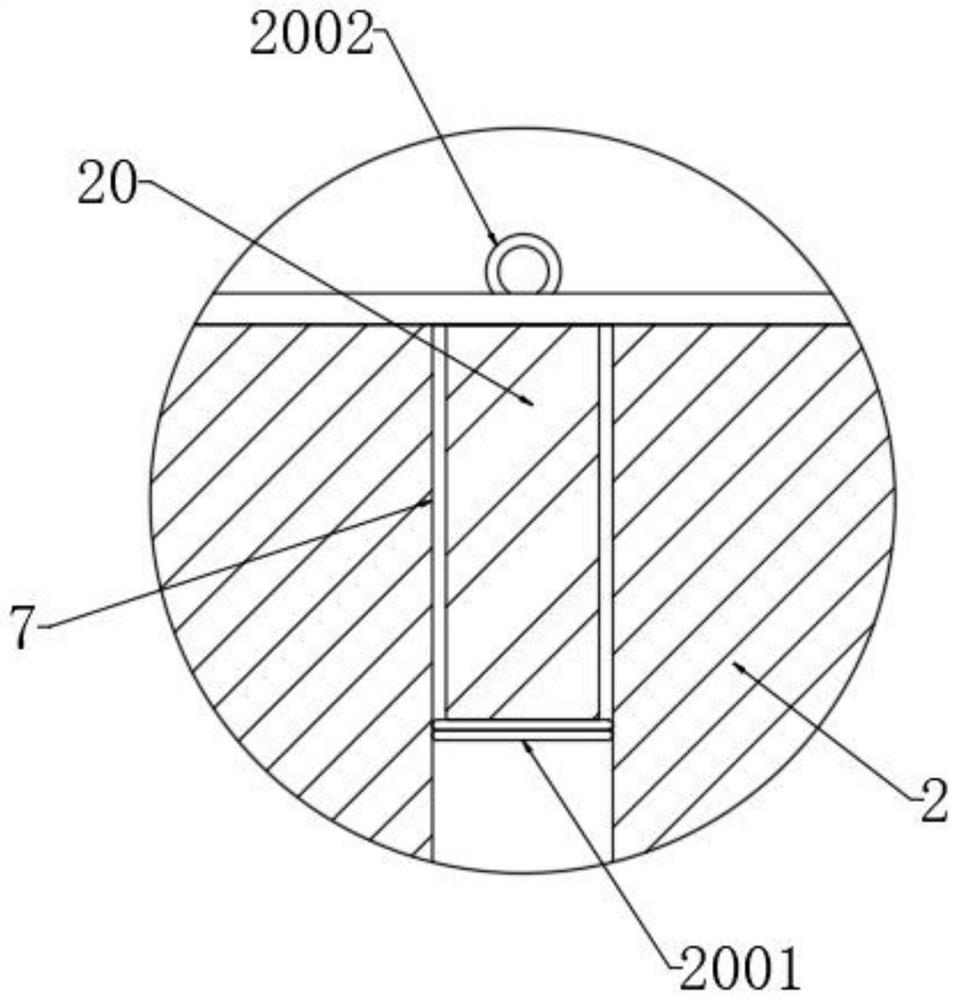

[0041] see Figure 1-7 , an internal decontamination type cone crusher for mines, comprising a crusher driving mechanism 1, the outer end of the crusher driving mechanism 1 is rotatably connected to a thrust plate 2, the outer end of the thrust plate 2 is fixedly connected to a fixed lining plate 3, and the fixed lining plate 3. A movable liner 4 is installed on the outer side. An I-shaped cavity 5 is excavated inside the thrust plate 2. A water outlet pipe 6 is excavated at the outer end of the thrust plate 2. The water outlet pipe 6 is connected with the I-shaped cavity 5. The upper end of the thrust plate 2 is excavated. There are threaded holes 7, the threaded holes 7 communicate with the I-shaped cavity 5, the thrust plate 2 is fixedly connected with a magnetic strip 8, the magnetic strip 8 is located at the outer end of the I-shaped cavity 5, and the inner bottom of the I-shaped cavity 5 is fixed Connected with telescopic rod 9, the upper end of telescopic rod 9 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com