System and method for changing double-loop operation into single-loop operation of centrifugal machine cooling system

A centrifuge and dual-circuit technology, applied in centrifuges and other directions, can solve the problems of water pollution of cooling water, uncertain valve sealing, complicated operation process, etc., and achieve the effect of simple and reliable connection, obvious energy saving effect, and increase of outlet water temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

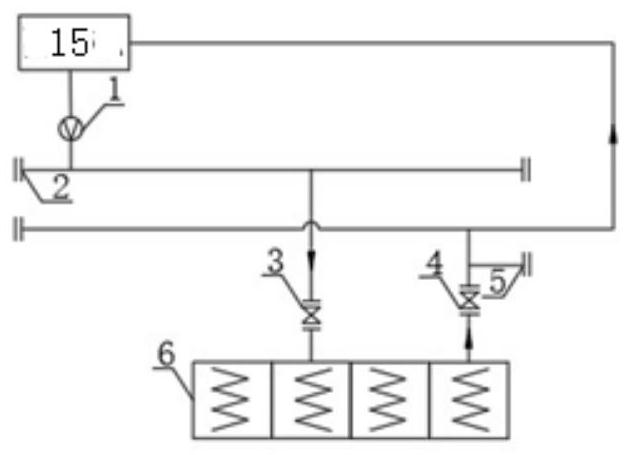

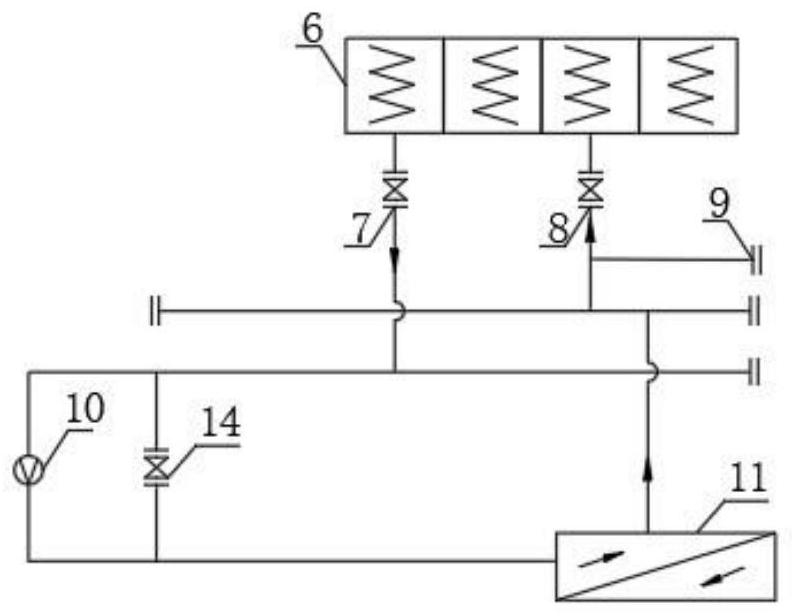

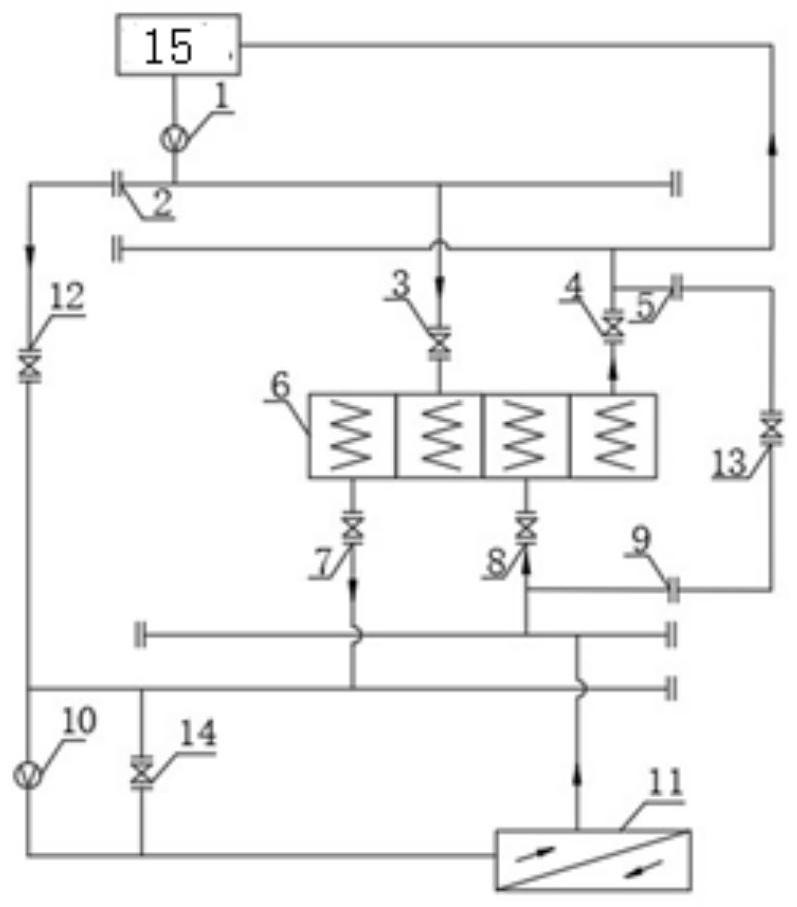

[0023] figure 1 with figure 2 It is a schematic description of the dual-circuit operation of the centrifuge cooling system before the transformation, image 3 is true figure 1 with figure 2 Changed to a schematic illustration of a single circuit.

[0024] Such as figure 1 As shown, the cooling water of the centrifuge is powered by the circulating water pump 1, enters the heat exchanger 6 through the cooling water inlet valve 3, and exchanges heat with the chilled water. After the temperature meets the operation requirements of the centrifuge, it is supplied to the centrifuge through the cooling water outlet valve 4 Machine, the reciprocating cycle continuously takes away the heat generated by the operation of the centrifuge.

[0025] Such as figure 2 As shown, the chilled water is powered by the circulating water pump 10, en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com