Special-shaped intermediate ring blank

A technology of intermediate rings and special-shaped rings, which is applied to engine components, machines/engines, metal rolling, etc., can solve the problems of high cost, many processing hours, and low material yield, so as to improve service life and reduce subsequent processing , Improve the effect of material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

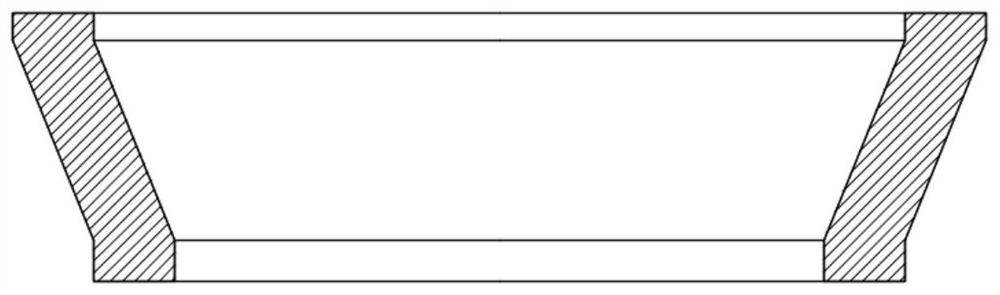

[0030] An aely shaped intermediate ring blank according to the present invention is formed by a small hole rectangular portion, a tapered middle portion, and a large hole rectangular portion; including the following steps:

[0031] Step 1: Determine the height of the blank according to the axial dimension of the ring

[0032] Hide o = (0.90 ~ 0.98) h d ;

[0033] Hide b0 = H b ;

[0034] Hide s0 = H s ;

[0035] hide s0 = H s ;

[0036] Medium, h 0 H d The axial height of the blank and the ring is respectively; H b0 H b The rectangular cross section height of the blank and the binduner of the riolent surface is respectively; H s0 H s Higher the rectangular cross section of the blank and the small hole end of the ring and the ring; H s0 H s The rectangular cross section of the blank and the small hole end of the roll and the ring is respectively.

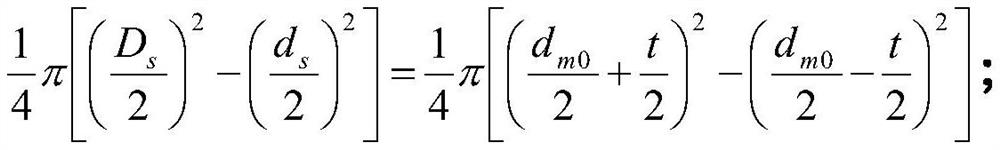

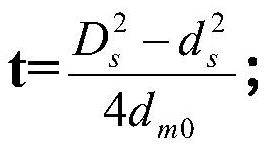

[0037] Step 2: Determine the average diameter of the blank small hole according to the average diameter of the rolling ratio K and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap