Polishing device for micromotor plastic accessory production

A technology of micro-motors and plastics, applied in the direction of grinding drive devices, grinding machine parts, grinding machines, etc., can solve the problems of needing a certain amount of time, low grinding efficiency, unfavorable continuous grinding process, etc., to achieve convenient turning and grinding The effect of high efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

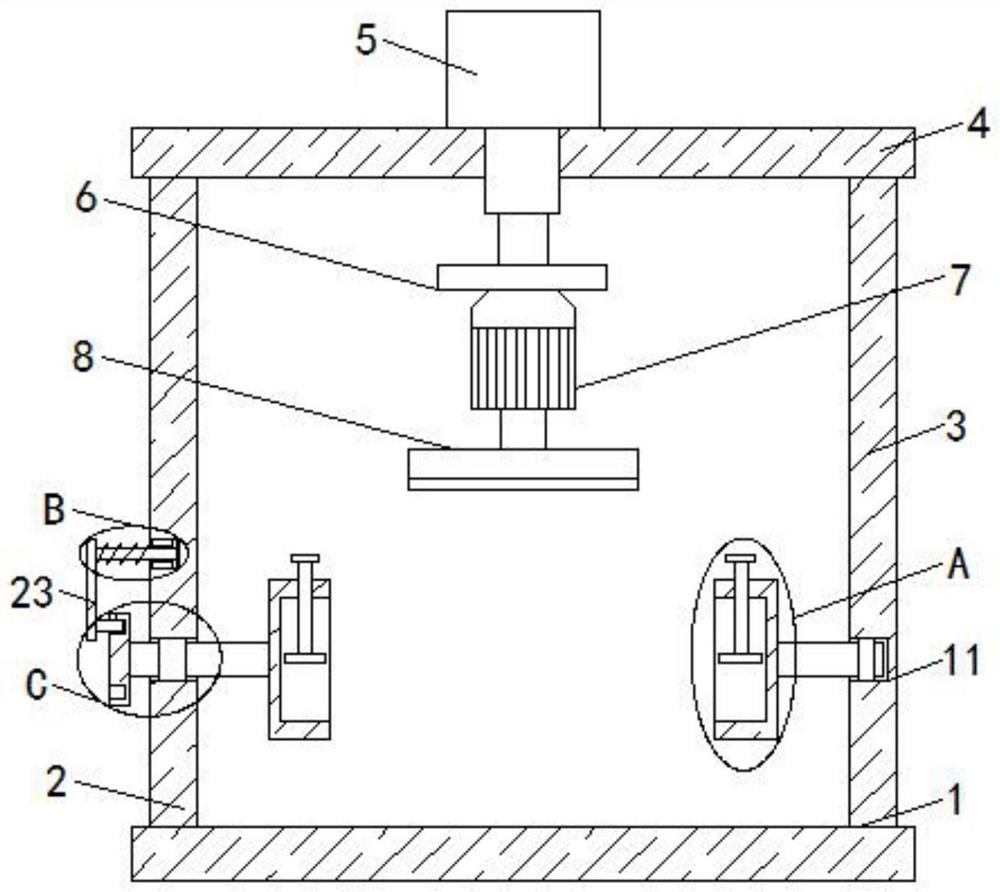

[0025] Example 1, please refer to Figure 1-4 , a grinding device for the production of micro-motor plastic parts, including a machine base 1, the top of the machine base 1 is fixedly connected with a first frame 2 and a second frame 3, and the tops of the first frame 2 and the second frame 3 The same top plate 4 is fixedly connected, the top of the top plate 4 is fixedly connected with a push rod motor 5, the output shaft of the push rod motor 5 extends through the top plate 4 to the bottom of the top plate 4 and is fixedly connected with a fixed plate 6, and the bottom of the fixed plate 6 is fixed A grinding motor 7 is connected, and the output shaft of the grinding motor 7 is fixedly connected with a grinding disc 8. Both the first frame 2 and the second frame 3 are rotatably connected with a fixed clamping mechanism, and the two fixed clamping mechanisms are compatible. Matching, the side of the first frame 2 away from the second frame 3 is slidingly connected with a posi...

Embodiment 2

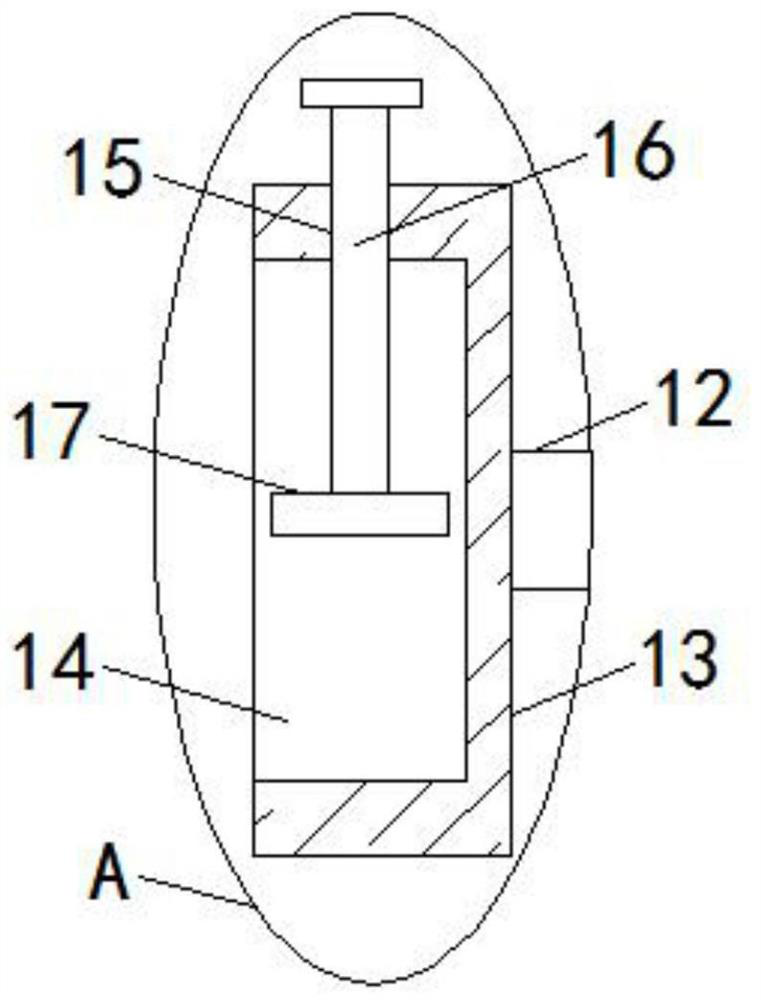

[0026] Example 2, please refer to figure 2 , the fixed clamping mechanism includes a first rotating rod 10, a second rotating rod 12, a clamping seat 13, a fastening bolt 16, a fixed plate 17 and a hand wheel 18, and the first frame 2 is provided with a rotating hole 9, and the second A rotating rod 10 is rotationally connected with the rotating hole 9, and the second frame 3 is provided with a rotating groove 11 near the side of the first frame 2, and the second rotating rod 12 is rotationally connected with the rotating groove 11, and two clamping seats 13 The sides away from each other are respectively fixedly connected with the adjacent ends of the corresponding first rotating rod 10 and the second rotating rod 12. The sides of the two clamping seats 13 close to each other are provided with clamping grooves 14. The top of the holder 13 is provided with threaded holes 15, and the two fastening bolts 16 are respectively connected to the corresponding threaded holes 15 for r...

Embodiment 3

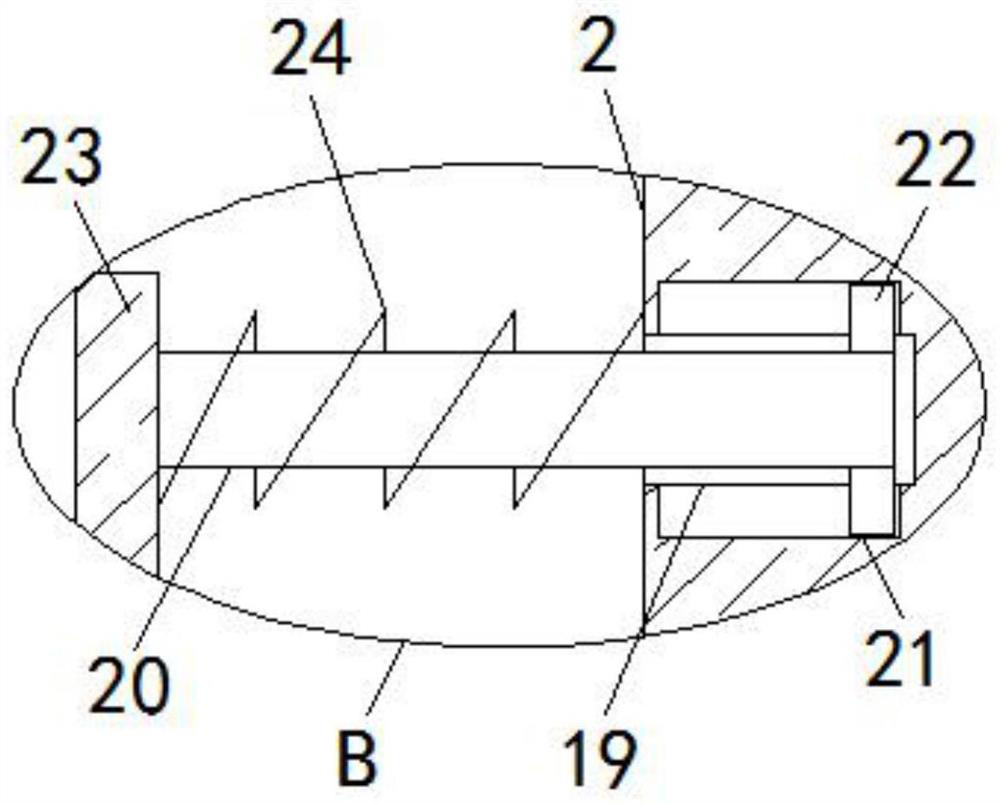

[0027] Embodiment three, please refer to image 3 , the positioning mechanism includes a positioning rod 20 and two reset blocks 22, the first frame 2 is provided with a positioning groove 19 on the side away from the second frame 3, and the positioning rod 20 is slidingly connected with the positioning groove 19, and the top of the positioning groove 19 Both the inner wall and the bottom inner wall are provided with reset grooves 21, and two reset blocks 22 are respectively slidably connected with the corresponding reset grooves 21, and the ends of the two reset blocks 22 that are close to each other extend into the positioning groove 19 and connect with the positioning rod 20. The top and bottom are fixedly connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com