Robot gripper capable of preventing scratches on surfaces of objects

A robot gripper and scratch technology, applied in the field of robotics, can solve problems such as surface damage and scratches on the surface of objects, and achieve the effect of reducing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

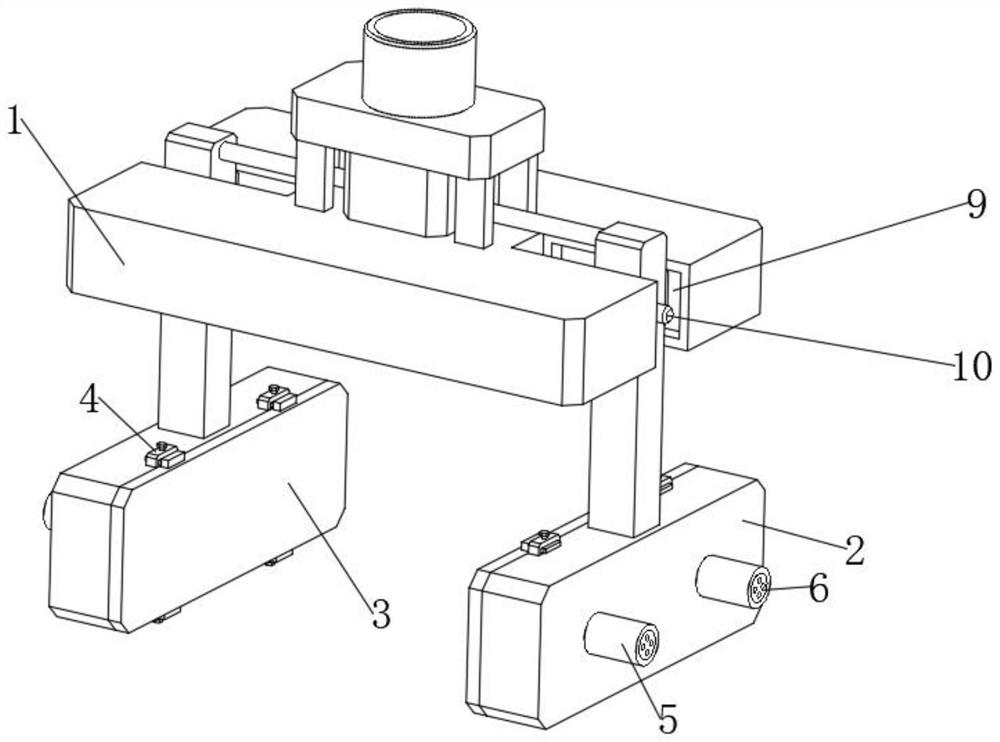

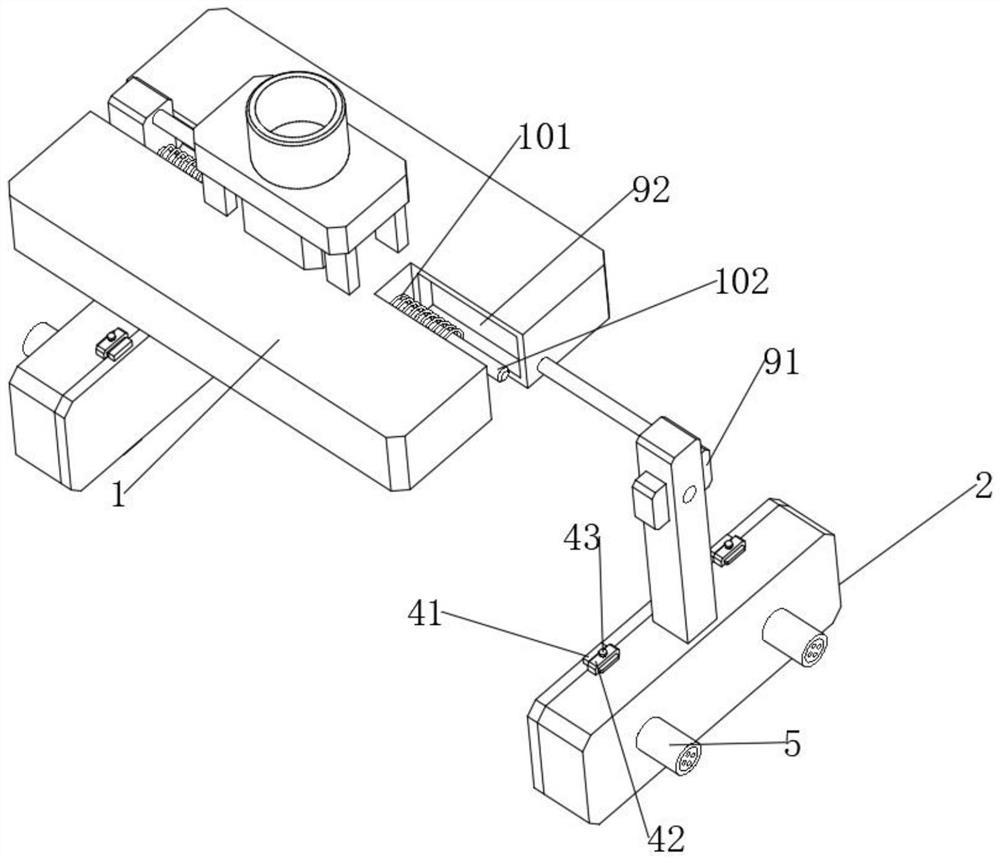

[0039] see Figure 1 to Figure 4 , a robot gripper for preventing scratches on the surface of objects, including a fixed plate 1, a claw plate 2 is slidably arranged on the fixed plate 1, a protective air cushion 3 is installed on the claw plate 2, and a circulation groove is also arranged on the claw plate 2 21, the circulation groove 21 penetrates into the protective air cushion 3;

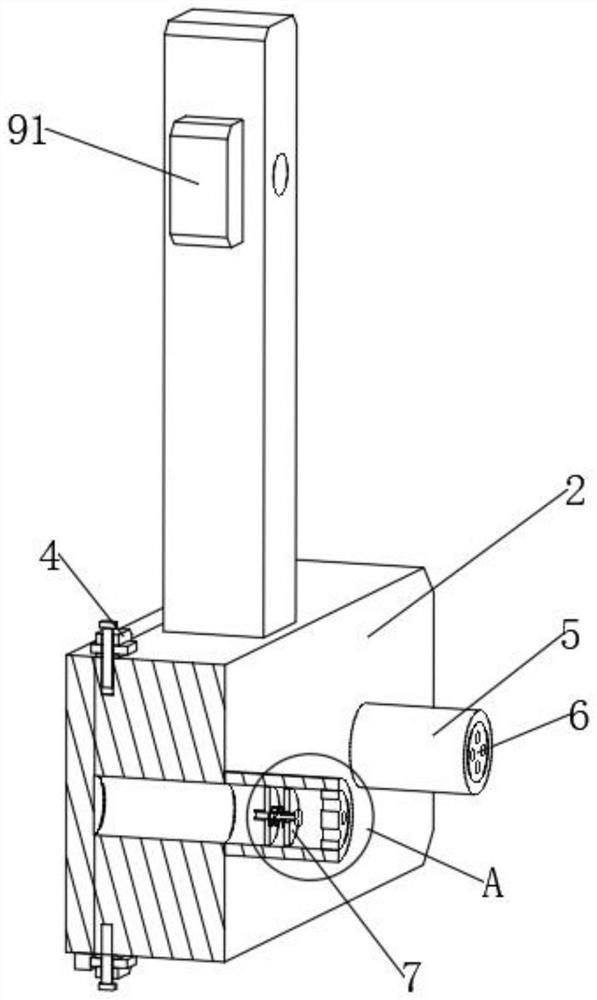

[0040] The claw plate 2 is provided with a flow pipe 5, and the flow pipe 5 is provided with a sealing mechanism 7. The sealing mechanism 7 includes a piston plate 71 installed in the flow pipe 5. The piston plate 71 is provided with a pipeline 73, and the flow pipe 5 is still sliding. A sealing plate 72 is provided, and the sealing plate 72 is slidably arranged on the pipe 73;

[0041] A communication groove 74 is opened on the pipe 73, and the communication groove 74 is used for air intake.

[0042] In this embodiment: since the manipulator is mostly made of a relatively strong alloy, when g...

Embodiment 2

[0048] This embodiment is an explanation made on the basis of Embodiment 1, please refer to Figure 1 to Figure 4 , the piston plate 71 is also provided with a connecting spring 76, and the piston plate 71 is elastically connected between the connecting spring 76 and the sealing plate 72;

[0049] The connection spring 76 is provided on the outer surface of the pipe 73 .

[0050] A gasket block 75 is also arranged on the pipeline 73 , and the gasket block 75 is used for sealing the sealing plate 72 .

[0051] In this embodiment: the piston plate 71 is provided with a connecting spring 76, and the piston plate 71 is elastically connected to the sealing plate 72 through the connecting spring 76, so that when the sealing plate 72 moves towards the piston plate 71 under the action of air pressure When sliding, the connecting spring 76 will be squeezed, so that it accumulates elastic potential energy. When the sealing plate 72 is no longer under the action of air pressure, the con...

Embodiment 3

[0055] This embodiment is an improvement made on the basis of Embodiment 2, please refer to Figure 1 to Figure 4 , the flow pipe 5 is also provided with a filter 6, the filter 6 is used to filter the air entering the flow pipe 5. . In this embodiment: due to the dust in the air, the manipulator is mostly used in environments with poor air quality such as factories. If the air entering the circulation pipe 5 is not filtered, the dust will easily block the circulation groove 21 so that the air cannot enter normally. In the protective air cushion 3, if the particle dust or impurities mixed in the air enter the protective air cushion 3, when the protective air cushion 3 contacts the surface of the article to generate pressure, the dust or impurities are easy to damage the protective air cushion 3.

[0056] Filtration: a filter screen 6 is arranged on the flow pipe 5, and the filter screen 6 can filter the air entering the flow pipe 5, thereby preventing dust and impurities in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com