Adjustable packaging box assembly line device

An assembly line, packaging box technology, applied in transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of waste of human, material and financial resources, cumbersome processes, and large limitations, so as to improve the efficiency of production change and improve the resolution. rate, avoid the effect of weakening the intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

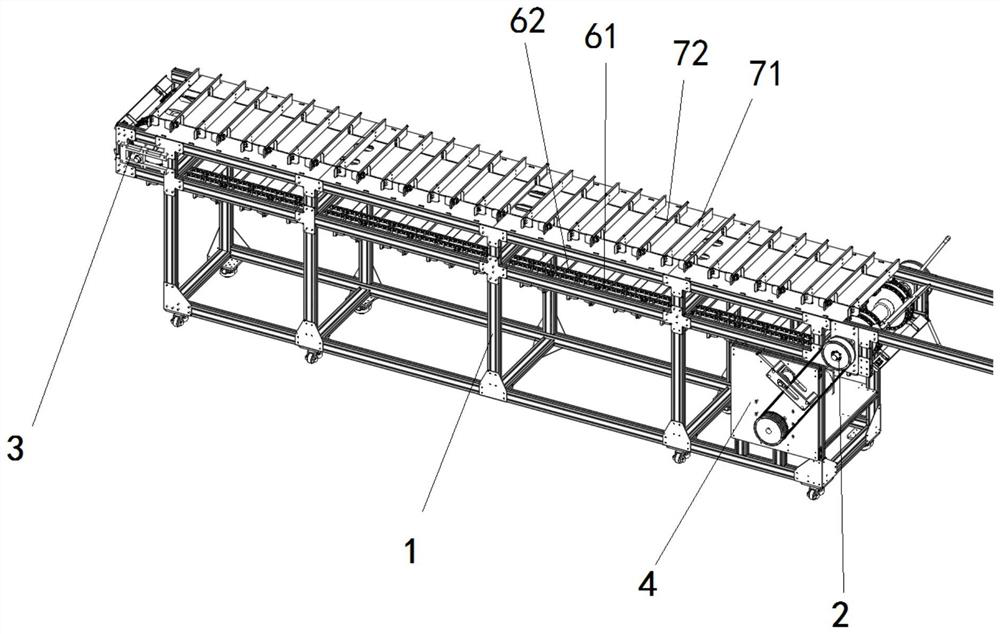

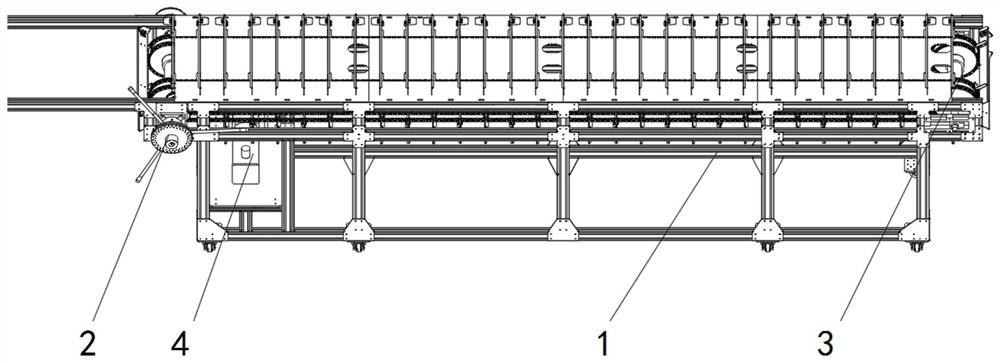

[0029] Refer to attached Figures 1 to 5 As shown, the adjustable packing box assembly line device in this embodiment includes an assembly line support 1 and a phase adjustment driving shaft system 2 and a phase adjustment driven shaft system 3 arranged thereon.

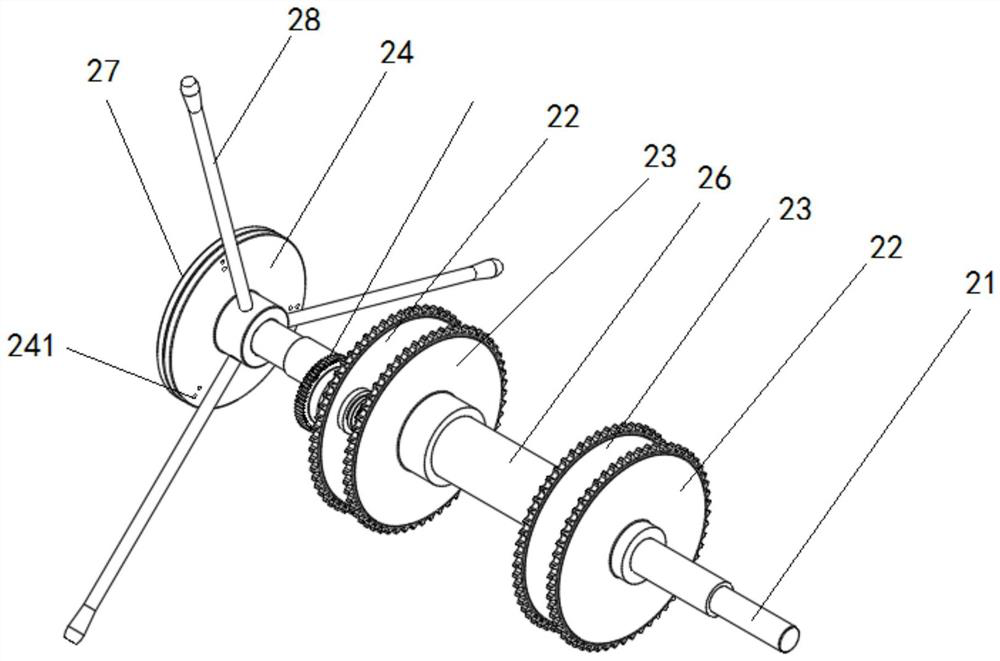

[0030] The shown assembly line support 1 adopts aluminum profile support. The phase adjustment drive shaft system 2 includes a drive shaft 21 connected to the motor 4, two drive sprockets 22, two driven sprockets 23, and a phase adjustment index plate 24 and planets arranged on the drive shaft 21. gear train. The two driving sprockets 22 are fixedly connected to the driving shaft 21 through common flat keys 25 . The two driven sprockets 23 are arranged between the two driving sprockets 22 through hollow bushings 26 . The phase adjustment dial 24 is arranged on the power distal end of the drive shaft 21 . The planetary gear train includes a primary sun gear 51 and a primary spur planetary gear 52 meshing with it, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com