Glass cover plate hot bending equipment and hot bending method thereof

A glass cover and equipment technology, applied in glass manufacturing equipment, glass molding, glass reshaping, etc., can solve the problems of manual switching, limited size and low glass cover, and achieve the goal of avoiding deformation and convenient bending Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

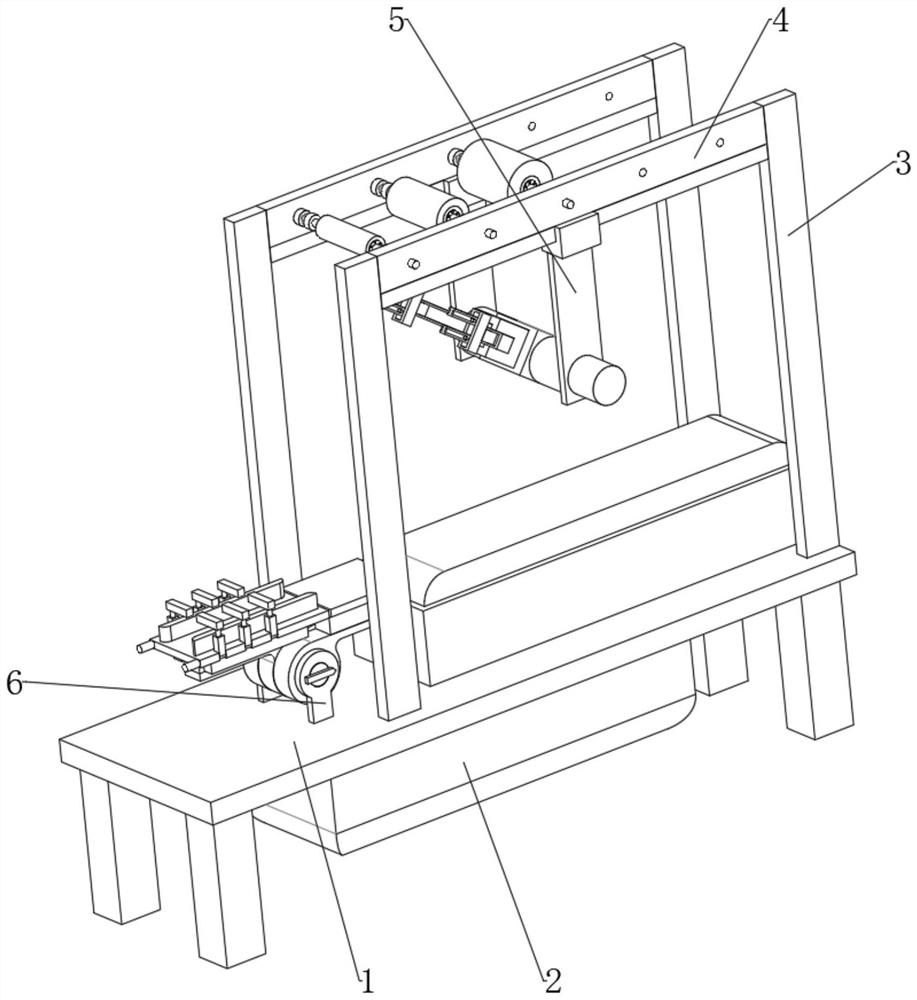

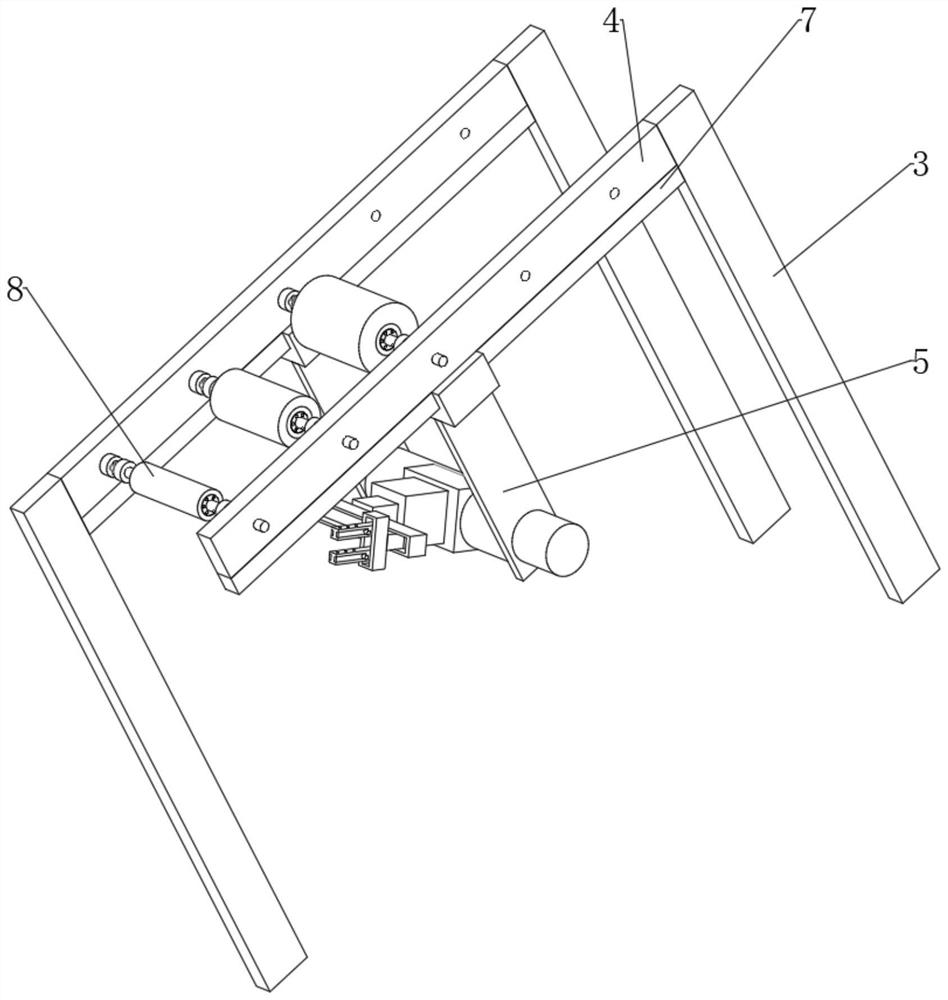

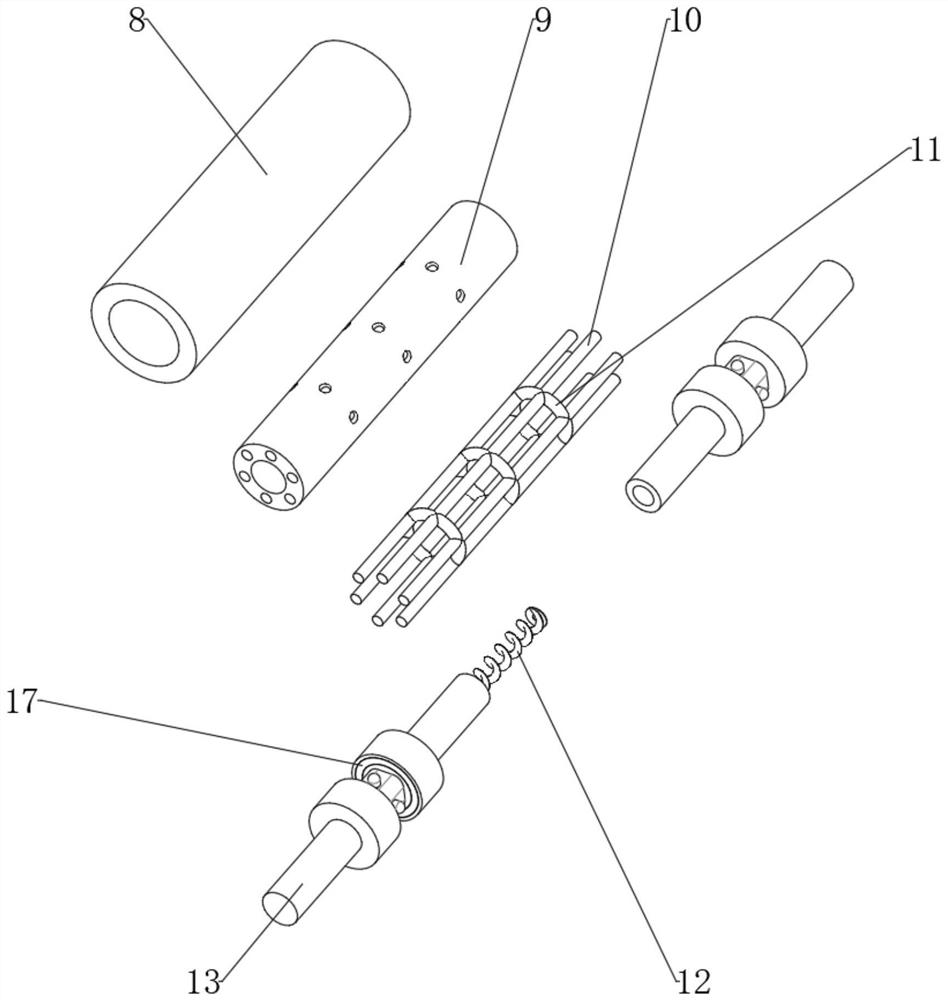

[0031] Such as Figure 1-Figure 8 As shown, the glass cover hot bending equipment provided in this embodiment includes a frame 1 and a bending mechanism arranged on the outer wall of its top end, the outer wall of the top of the frame 1 is fixedly connected with auxiliary components, and the bending mechanism includes 1 A plurality of stands 3 on the outer wall of the top and a beam 4 fixedly connected to the outer wall of the top of the stand 3, the outer wall of the bottom of the beam 4 is provided with a switching assembly, and there are multiple sets of single-tube assemblies arranged between the two beams 4, and the single-tube assembly includes two An inserti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap